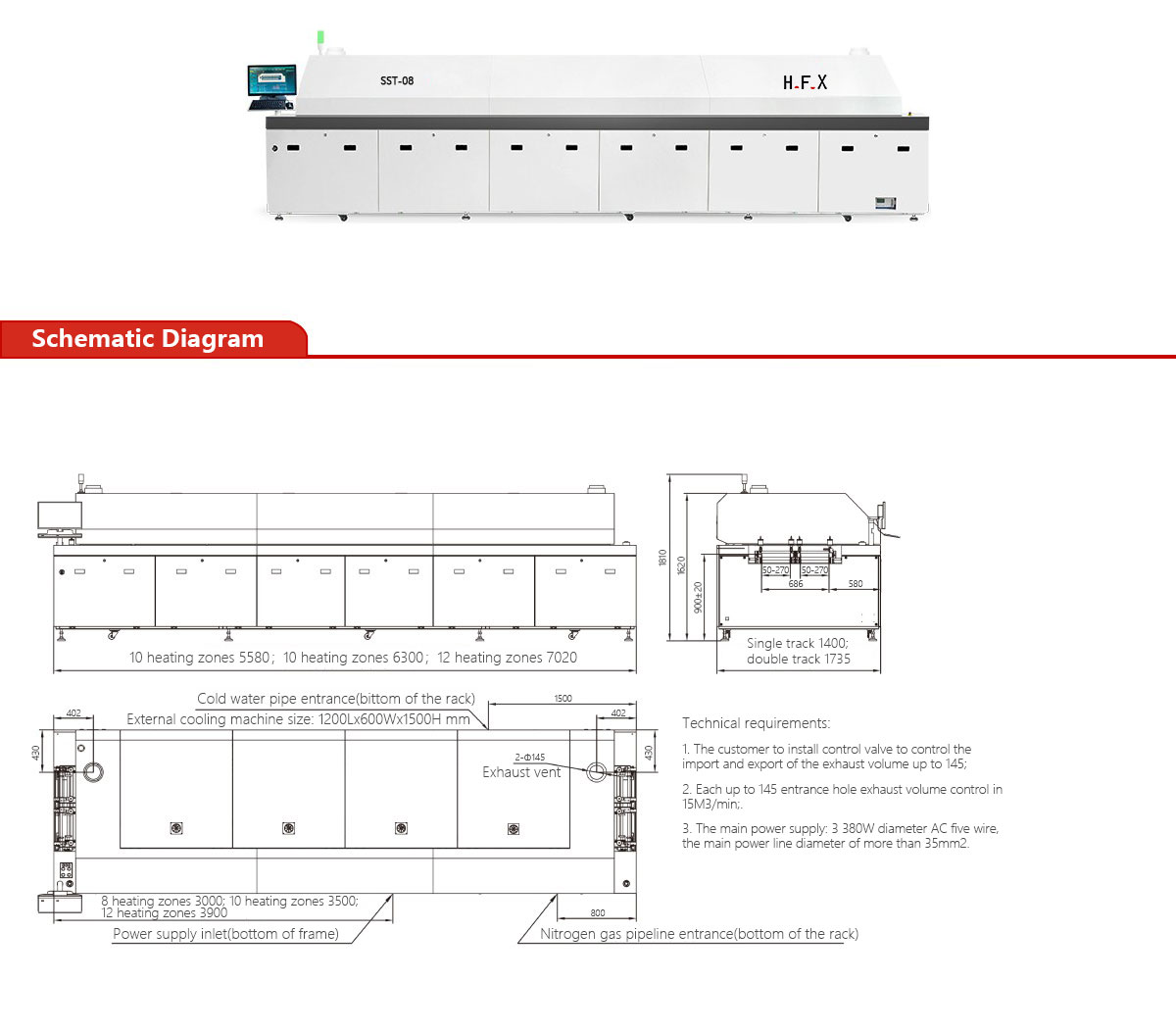

Reflow soldering SST series features:

Adopting double-sided guide rails and special hardening treatment, it is sturdy, durable, and highly interchangeable;

Adopting stainless steel chain with edge guard and anti jamming plate, practical and reliable;

New flux recycling system, fully modular design, easy and fast maintenance, reducing maintenance time and costs;

Patent hot air system, with more efficient hot air convection and faster thermal compensation;

New furnace structure design, multi-layer insulation, effectively reducing working environment temperature.

FAQ:

Q: What is reflow technique?

A: Reflow soldering is a fundamental technique in electronics assembly. It involves heating solder paste to a controlled temperature, allowing it to melt and form secure electrical connections between components and printed circuit boards (PCBs) during the surface mount technology (SMT) process.

Q: Why do you use flux when soldering?

A: Flux is used in soldering to remove oxides, contaminants, and promote wetting of the solder. It ensures a clean, reliable solder joint by facilitating the flow of molten solder and preventing defects like solder bridges or cold joints.

Q: Why is it called reflow soldering?

A: Reflow soldering gets its name from the process of "reflowing" or melting the solder paste. During reflow, solder paste transitions from a solid to a liquid state, forming precise and reliable connections between components and PCBs.

Q: How many times can you reflow a PCB?

A: Reflowing a PCB multiple times is generally not recommended. Each reflow cycle can subject components to thermal stress and potentially affect solder joint integrity. Minimizing the number of reflows helps ensure the reliability of electronic assemblies.

H.F.X - Our Company

About H.F.X:

H.F.X is a leading provider of factory planning solutions and industrial inspection solutions. We have 4 wholly-owned factories that provide professional consulting and services to global customers. We have over 11 years of experience in electronic integrated solutions and industrial testing solutions. We not only provide a complete set of equipment, but also offer comprehensive technical support and services, and provide customers with more reasonable professional advice. We help many clients establish factories in LED, TV, mobile phone, DVB, EMS, and other industries around the world. We will establish factories in LED, TV, mobile phone, DVB, EMS, and other industries around the world. We are trustworthy.

Exhibition:

For SMT factory setup and industrial non-destructive testing, we can provide you with:

1. We provide you with complete SMT solutions and industrial testing solutions

2. We Provide Core Technology With Our Equipments

3. We provide the most professional technical services

4. We have rich experience in establishing SMT factories and industrial testing

5. We can solve any problems related to SMT and industrial testing

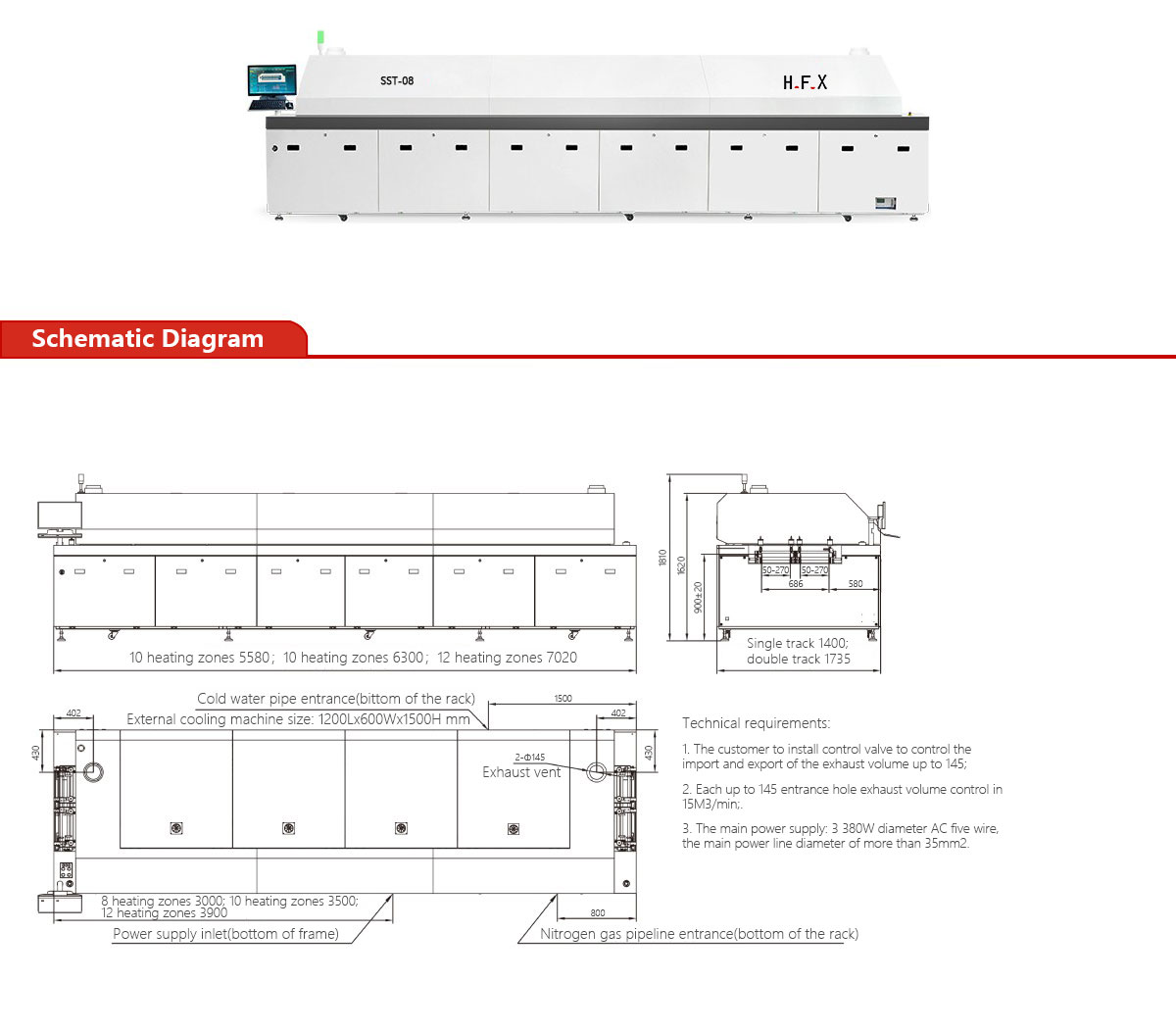

Reflow soldering furnace SST series