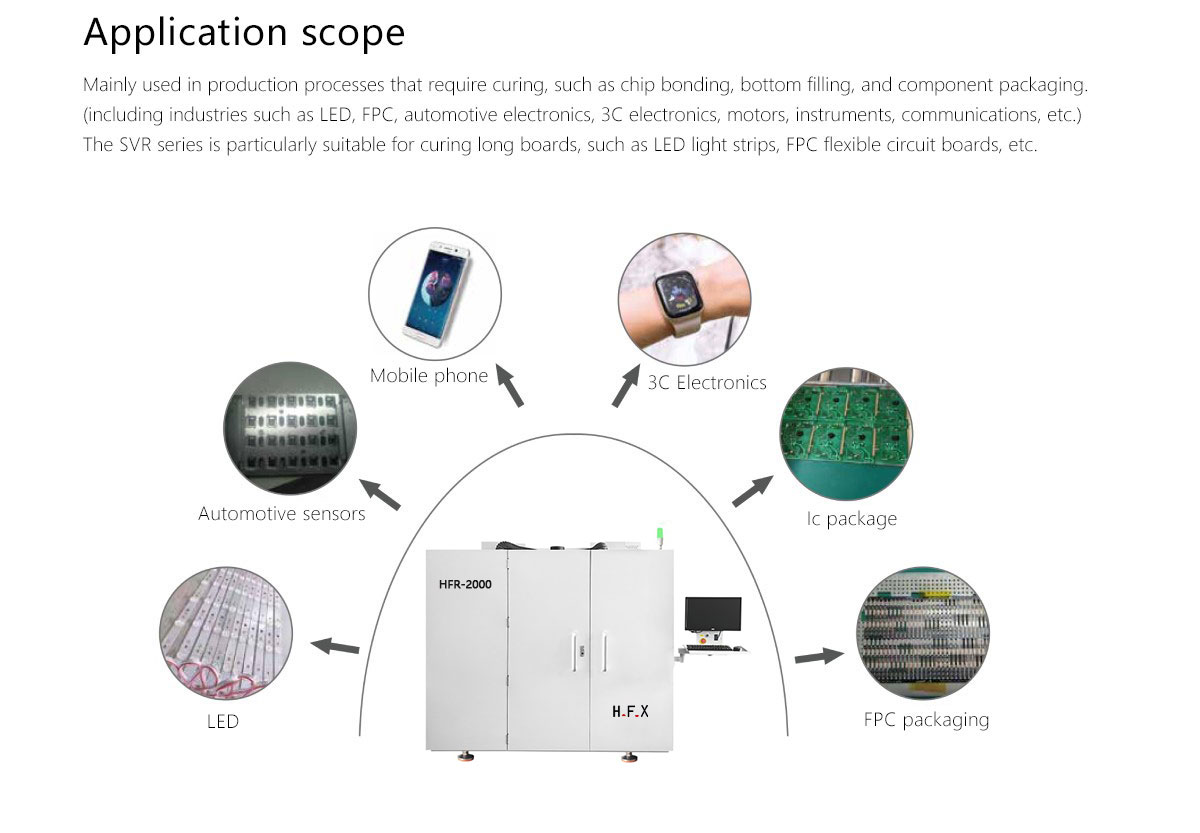

HFR series on-line vertical oven, newly upgraded design, more humanized. With segmented heating and independent temperature control, the heating is more efficient and temperature control is more accurate. The transportation system is stable and reliable, and the operation and maintenance are convenient, automatic loading and unloading, intelligent production,high production efficiency. Small size, which effectively shorten the length of production line. The vertical oven SVR-V series are

even more advantageous for the curing applications of long boards, up to1200mm. Hundreds,thousand, and ten thousand cleanliness equipment to meet the requirements of clean production process.

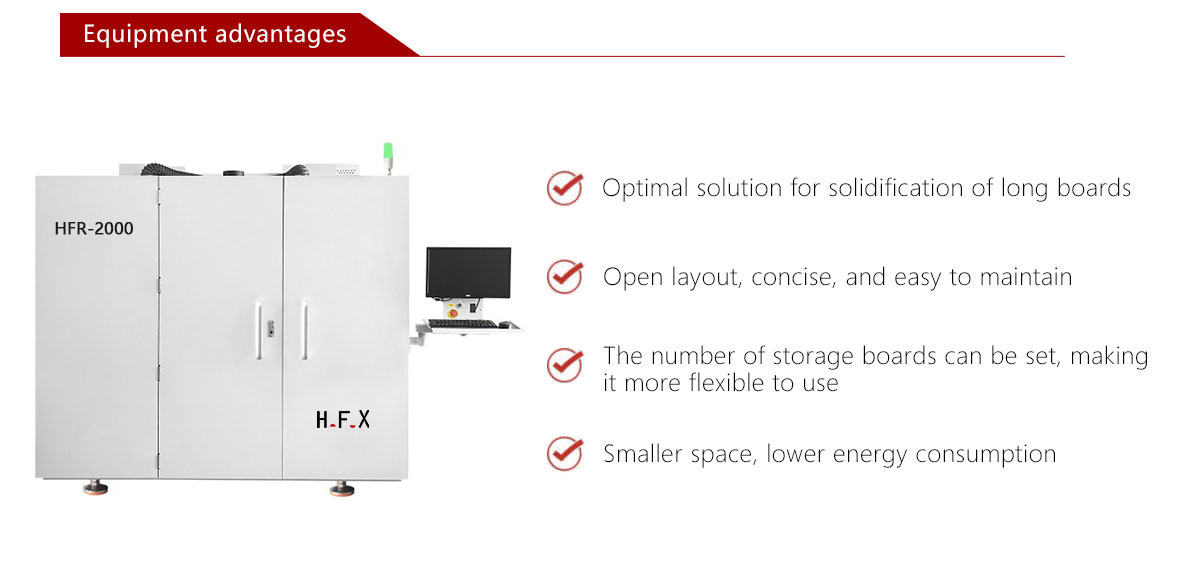

Advantages:

Optimal solution for longboard curing

Open layout, simple, easy to maintain

The storage quantity can be set, flexible operation

Smaller space, lower energy consumption

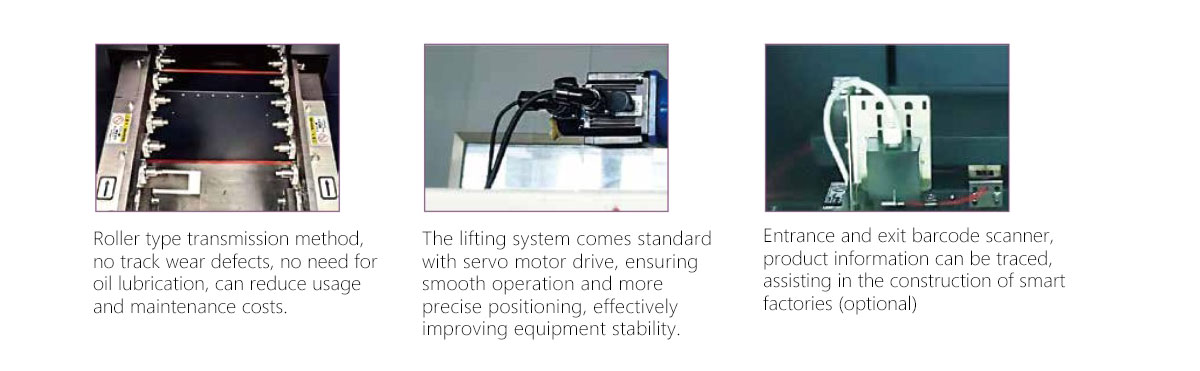

Roller type conveying mode, no rails wear risk, no need oil lubrication,reduce the use and maintenance costs

Lifting system with standard servo motor driving, smooth operation, more accurate positioning, effectively improve the stability

With barcode reader, product information can be traced to support smart factory construction.(option)

Product parameters:

| SVR-V Specification | ||||

| Model | HFR-2000 | HFR-2000D | HFR-2000L | Remarks |

| Machine Dimension | L1486xW1830xH2100mm | L1736xW1930xH2150mm | L2036xW2030xH2150mm | |

| Machine Weight | Approx.1300kg | Approx.1600kg | Approx.1800kg | |

| Product size | MIN:W50*L200mm | |||

| MAX:W250*L520mm | MAX:W350*L900mm | MAX:W450*L1200mm | ||

| Inlet height | 900±30mm | |||

| Storage type | Vertical storage | |||

| Storage quantity | 30pcs | Can be customized. | ||

| Layers spacing | 20mm | Can be customized. | ||

| Curing time | ≥1min Curing time can be set. | |||

| Heating module | 4 Heating modules | 8 Heating modules | 8 Heating modules | Each module controls |

| temperature independently | ||||

| Temperature range | Room temp~200℃ | |||

| Warming up time | Approx.15min | Set temp 150℃ | ||

| Running power | Approx.4KW | Approx.5KW | Approx.6KW | |

| Temperature control accuracy | ±1℃ | |||

| Temperature deviation | ≤±2℃ | |||

| Abnormal alarm | Tricolor signal lamp +Human-machine interface prompt | |||

| Power supply | 3P5L 380V 50/60Hz | |||

> Customization can be made according to customer needs.