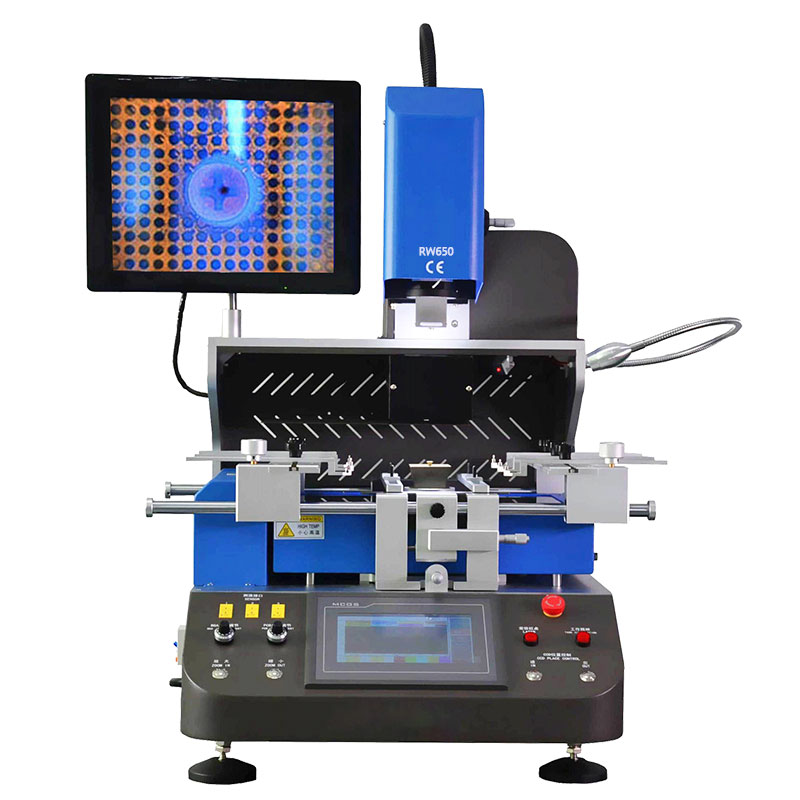

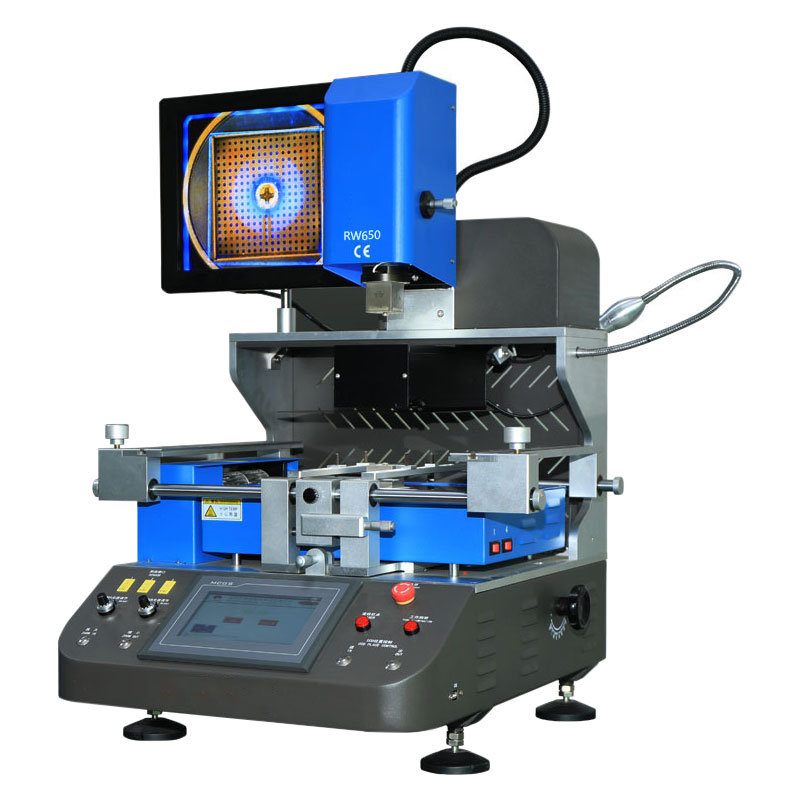

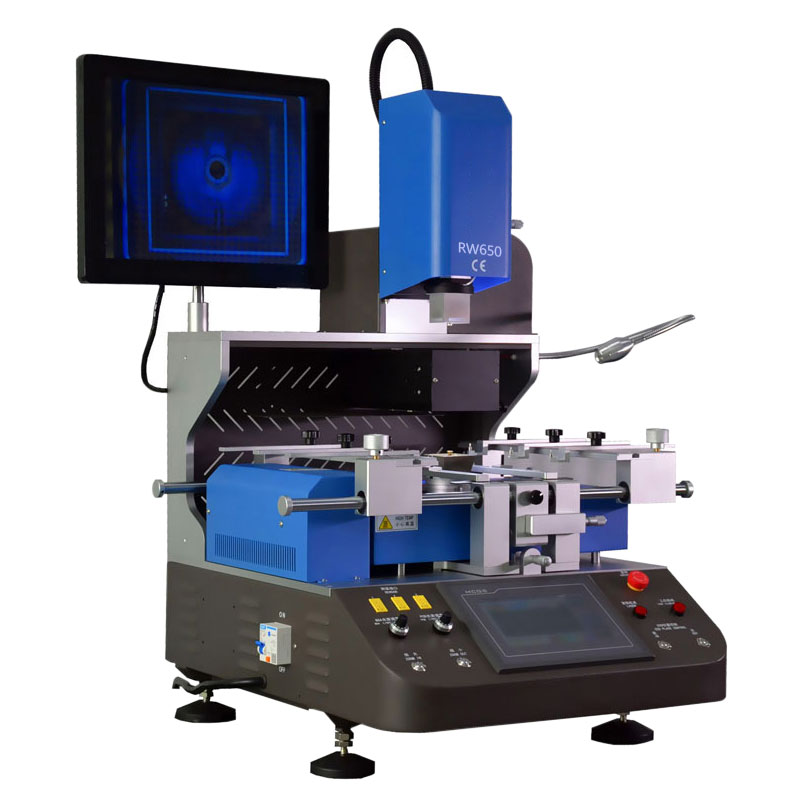

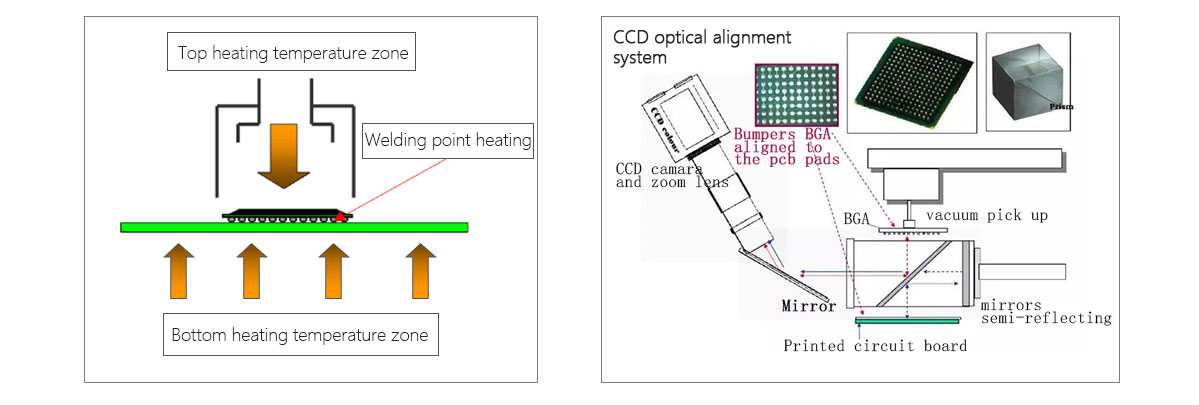

Equipment principle:

1.Based on operations such as heating, removing, cleaning, repositioning, and soldering BGA chips, to achieve repair and replacement of BGA packaging;

2.Heat the BGA chip through the top temperature zone, bottom temperature zone, and preheating temperature zone to melt the solder joints at the bottom

of the chip, and remove the chip from the circuit board;

3.By using the CCD optical alignment system, the solder joints at the bottom of the chip and the solder joints on the circuit board are accurately aligned, and

then the soldering is completed through automatic mounting;

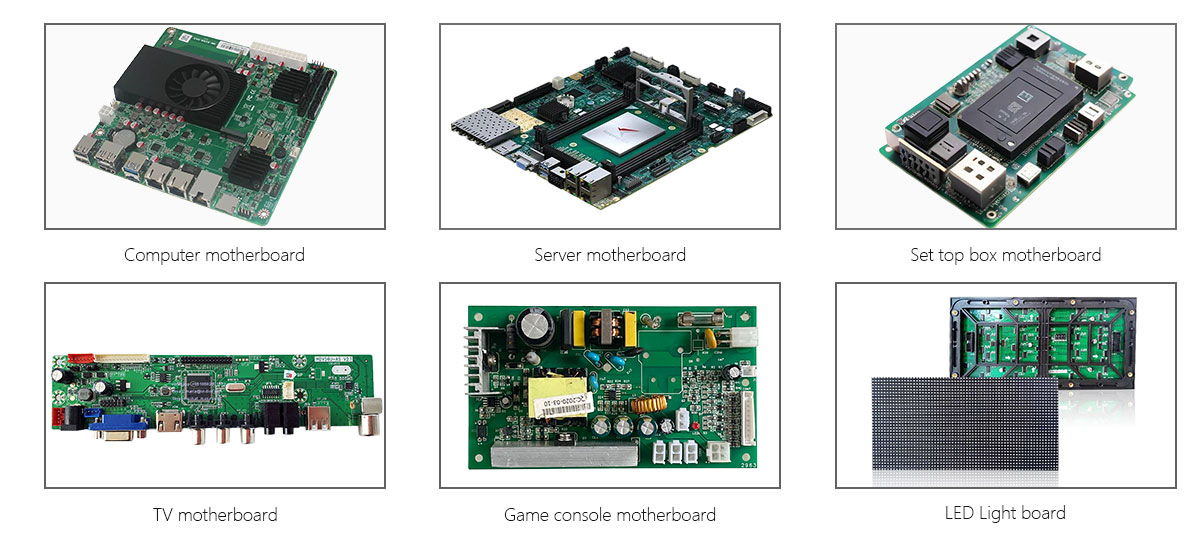

Application scope:

1.Suitable for repairing various types of circuit boards such as servers, game console motherboards, PC motherboards, SMT processing, motherboards, other communication motherboards, LCD TV motherboards, security products, tablets, intelligent terminals, etc;

2.Mainly targeting the repair of BGA/POP, PTH, WLESP, QFN, CHIP0201/01005, shielding frames/modules and other components on PCBA substrates;

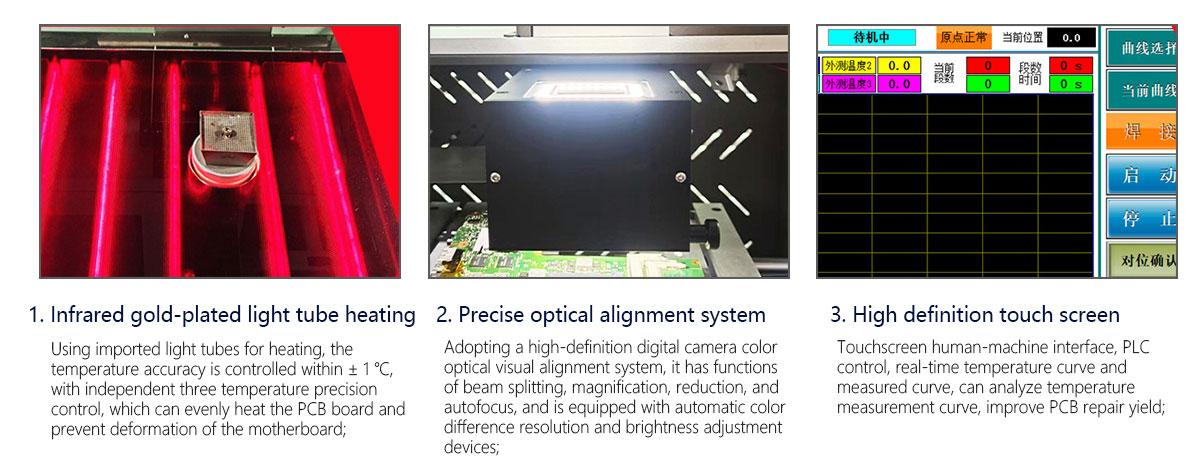

Feature Highlights:

Other functional features:

1. The upper heating head and mounting head of the machine are designed in an integrated manner, with five working modes: automatic welding, automatic disassembly, automatic mounting, semi-automatic, and manual, which can be freely switched to meet the different needs of special products;

2. Adopting touch screen human-machine interface PLC control, displaying 6 temperature curves at any time (including upper heating curve, lower heating curve, preheating temperature curve, and external measurement three curves, with three temperature measurement interfaces for external measurement, mainly used for BGA chip temperature curve temperature adjustment);

3. Eight stage constant temperature control, fully simulating reflow soldering process to ensure the improvement of welding yield, with temperature precisely controlled within ± 1 degree;

4. The machine has three independent heating zones on top and bottom (each zone can be independently set with the required heating temperature, time, and heating speed), and the first and second zones can simultaneously perform multiple sets and segments of temperature control;

5. Superior function: The air output of this machine can be saved according to the temperature curve, and different sizes of air output can be set for chips of different sizes. The electric automatic entry and exit of the alignment lens has a high degree of automation, which can avoid manual operation errors;

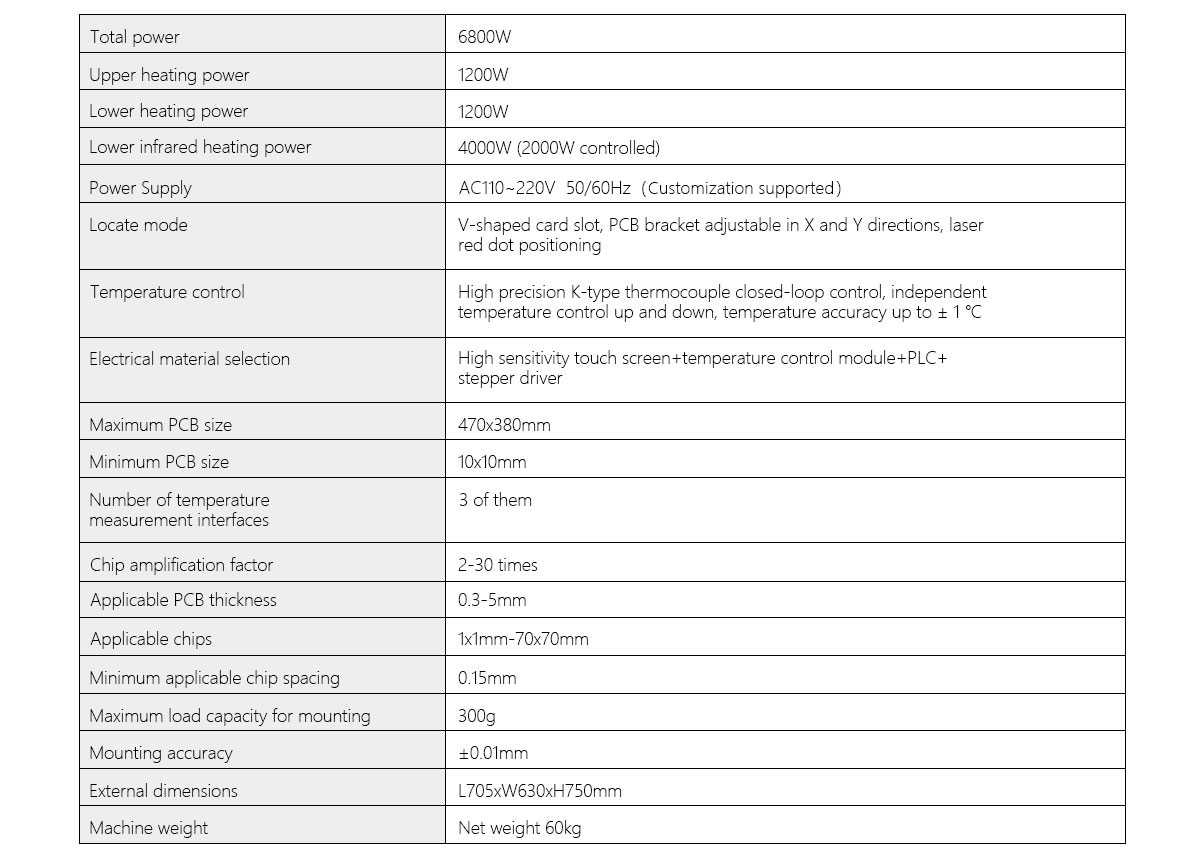

Equipment parameters:

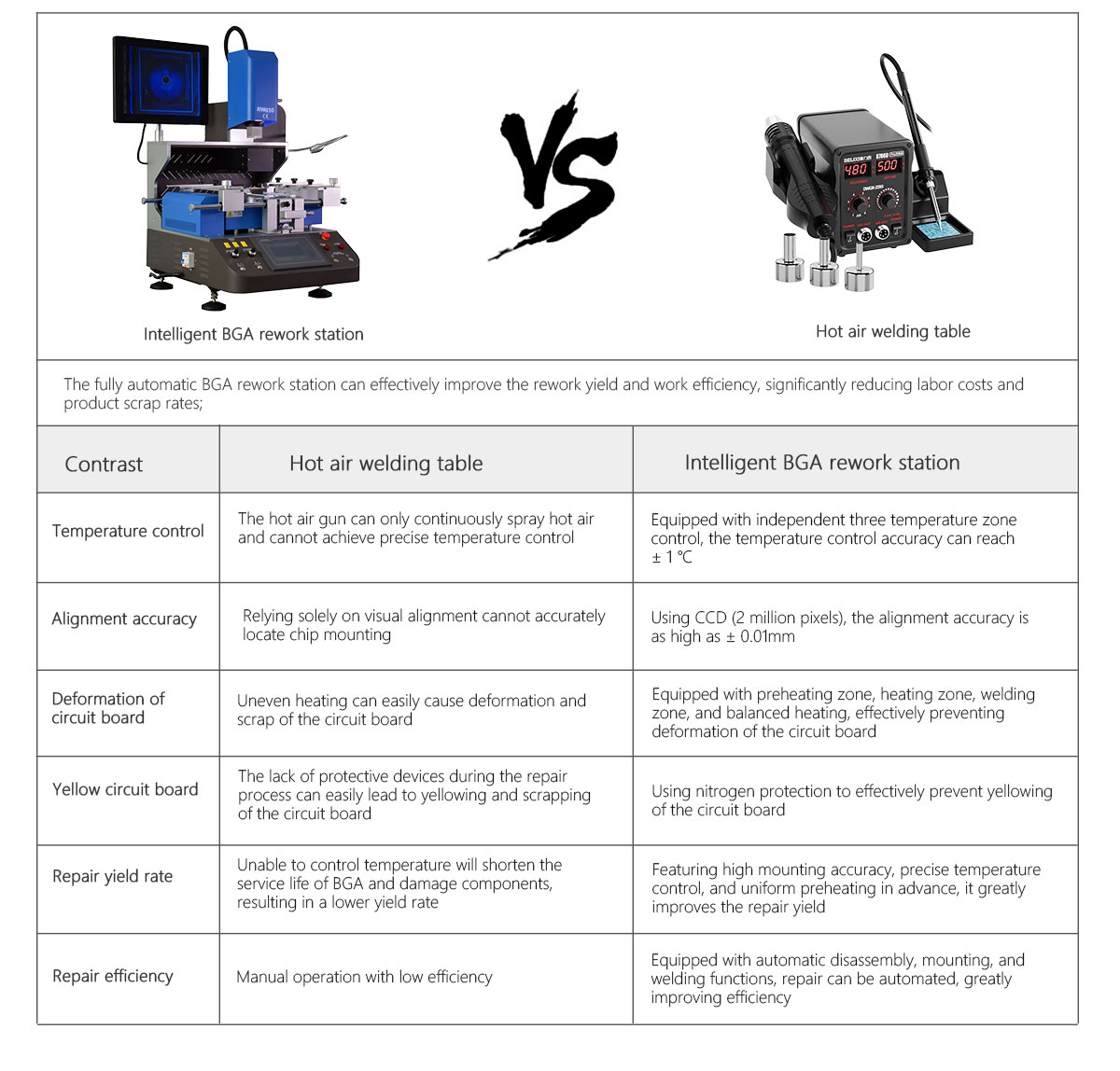

Why choose BGA rework station?