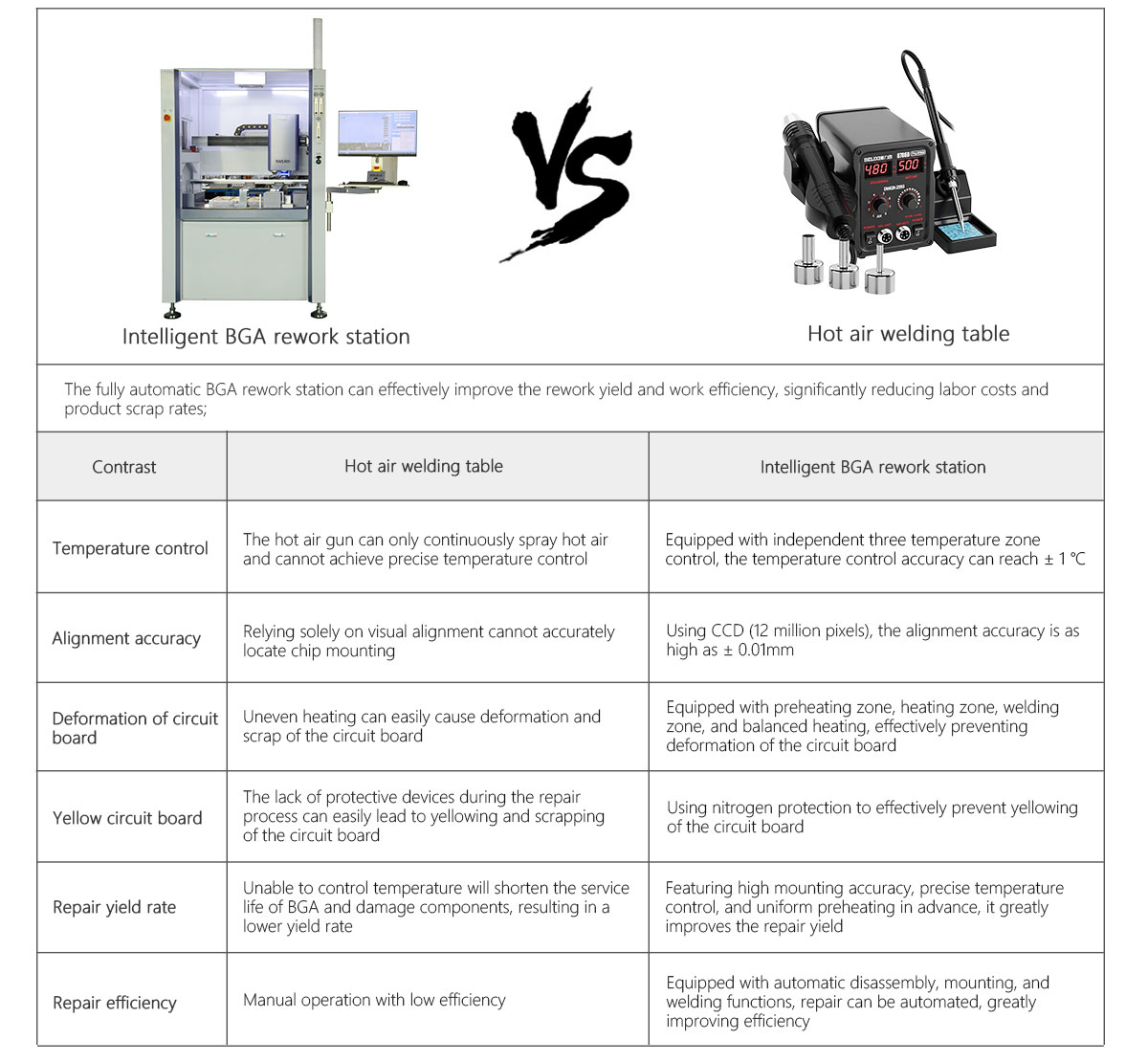

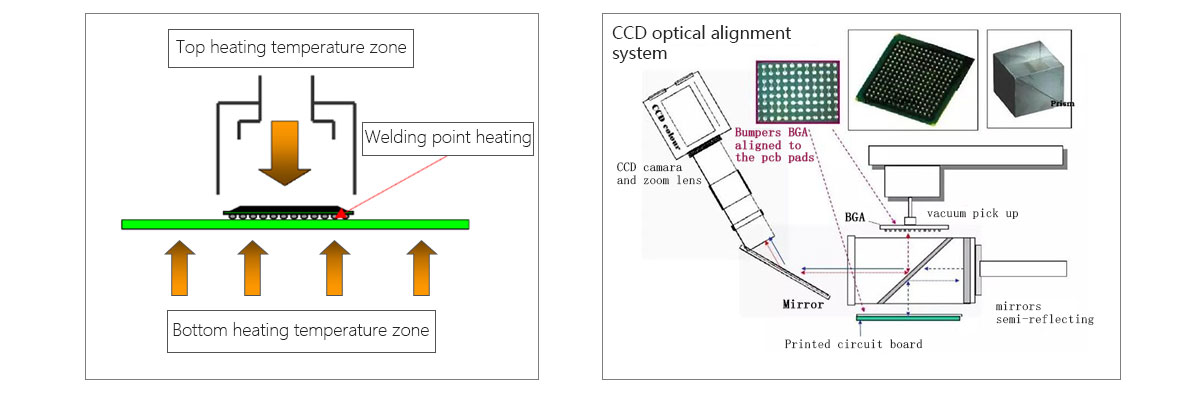

Equipment principle:

1.Based on operations such as heating, removing, cleaning, repositioning, and soldering BGA chips, to achieve repair and replacement of BGA packaging;

2.Heat the BGA chip through the top temperature zone, bottom temperature zone, and preheating temperature zone to melt the solder joints at the bottom of the chip, and remove the chip from the circuit board;

3.By using the CCD optical alignment system, the solder joints at the bottom of the chip and the solder joints on the circuit board are accurately aligned, and then the soldering is completed through automatic mounting;

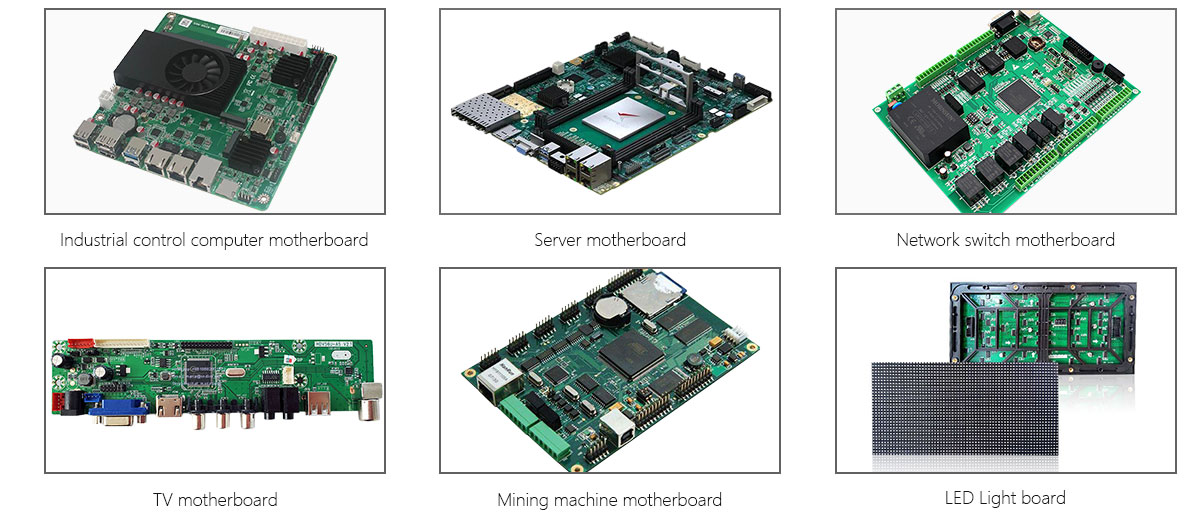

Application scope:

1.Suitable for repairing various types of circuit boards such as servers, game console motherboards, PC motherboards, SMT processing, motherboards, other communication motherboards, LCD TV motherboards, security products, tablets, intelligent terminals, etc;

2.Mainly targeting the repair of BGA/POP, PTH, WLESP, QFN, CHIP0201/01005, shielding frames/modules and other components on PCBA substrates;

Feature Highlights:

Other functional features:

1. Independent three temperature zones (upper temperature zone, lower temperature zone, infrared preheating zone), with the upper and lower temperature zones automatically moving to any position in the heating zone. When the upper heating head reaches the target chip position, the lower heating zone will automatically move to the bottom position of the target chip. The lower temperature zone can automatically adjust the heating position up and down. Realize that the PCB remains stationary on the fixture and the upper and lower heating heads can be moved to the target chip on the PCB.

2. Independent eight axis linkage, with eight motors driving all actions. Both the upper and lower temperature zones/PCB movements and the visual positioning system X/Y movements can be controlled by a computer, making the operation simple. It has memory function, suitable for batch repair to improve efficiency, and has a high degree of automation.

3. The heating head and mounting head are designed separately, with automatic rotation, alignment, welding, and automatic disassembly functions;

4. The ultra large bottom infrared preheating platform adopts the German imported Elstein dark infrared heating plate, which heats up quickly and evenly, with a preheating area of 550 * 400 mm. When repairing large-sized PCBs, the infrared heating has a pre preheating function. When starting the device, the infrared area heats up and preheats the PCB first. When the PCB temperature reaches the set trigger value, the upper and lower hot air begins to heat up. The advantage of doing so is to preheat the PCB first, reduce the heat loss caused by PCB heat absorption during the heating process, and the solder balls can reach the melting point faster, effectively preventing PCB deformation and improving the success rate of repair.

5. The X and Y direction mobile and unique overall design make full use of equipment space, achieving large area PCB repair with relatively small equipment volume. The maximum clamp size can reach 640 * 490mm (size can be customized according to needs), with no blind spots for repair;

6. Equipped with a built-in vacuum pump, the shaft can rotate freely at any angle, controlled by a high-precision stepper motor, and fine tuned for attaching suction nozzles;

7. The suction nozzle automatically recognizes the suction and mounting height, and the pressure can be controlled within a small range of 10 grams. It has zero pressure suction and mounting functions, suitable for smaller chips;

8.1200W pixel industrial vision camera automatically recognizes Marke point coordinates for positioning, with an accuracy of up to 10um and a maximum repairable component size of 80 * 80mm;

9. It can display real-time temperature curves, including set and measured curves, and analyze temperature measurement curves;

10.10 stage temperature rise (fall) ladder heating control, capable of storing a large number of temperature curves (more than 10000 sets) and real-time curve analysis;

11. Equipped with a nitrogen inlet for external nitrogen protection welding, making repairs safer and more reliable.

12. Industrial computer control, intelligent operation software, can achieve remote control after networking; Can be integrated with MES system; Optional camera for observing the melting point on the side of the solder ball, convenient for determining the curve.

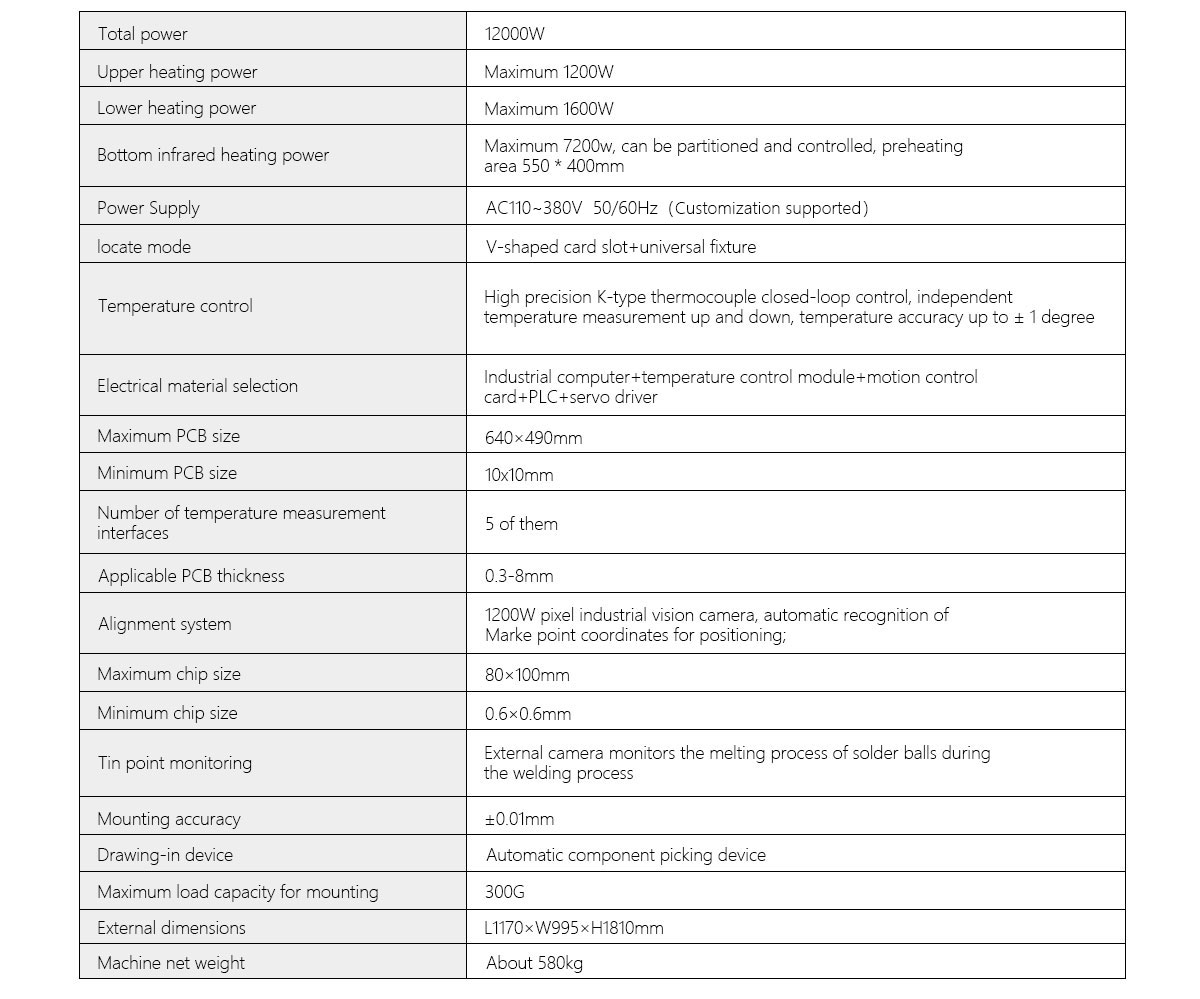

Equipment parameters:

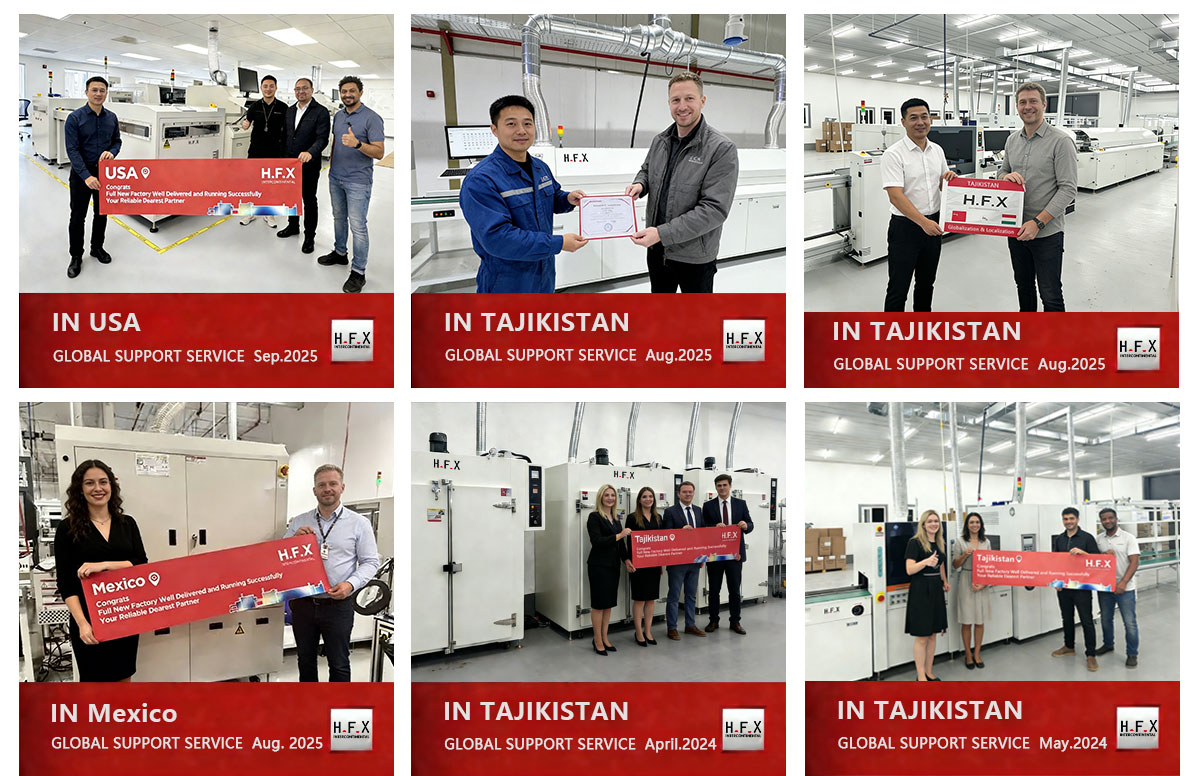

Why choose BGA rework station?