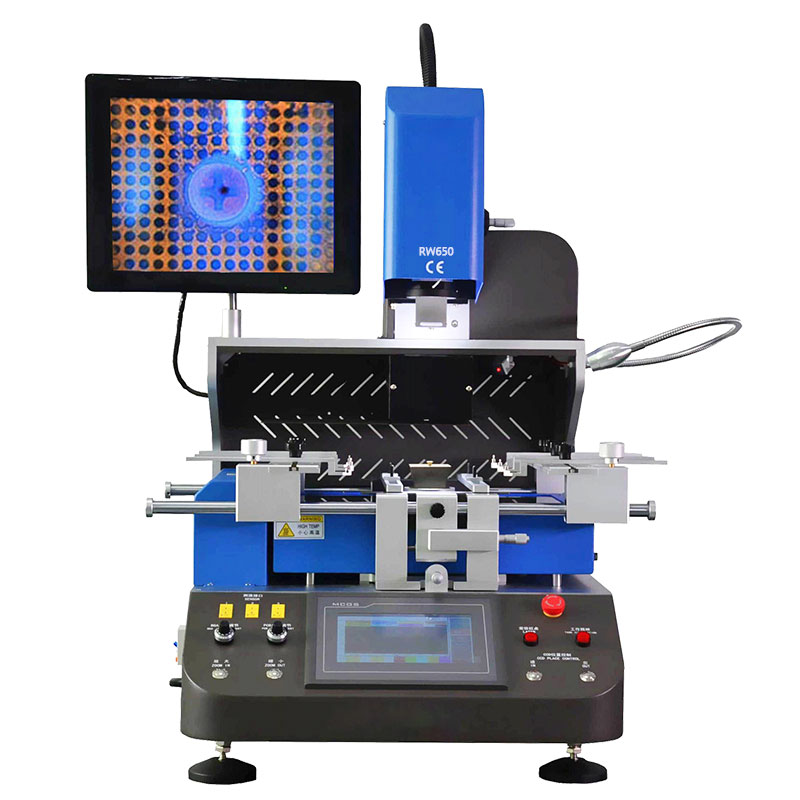

Equipment principle:

1.Based on operations such as heating, removing, cleaning, repositioning, and soldering BGA chips, to achieve repair and replacement of BGA packaging;

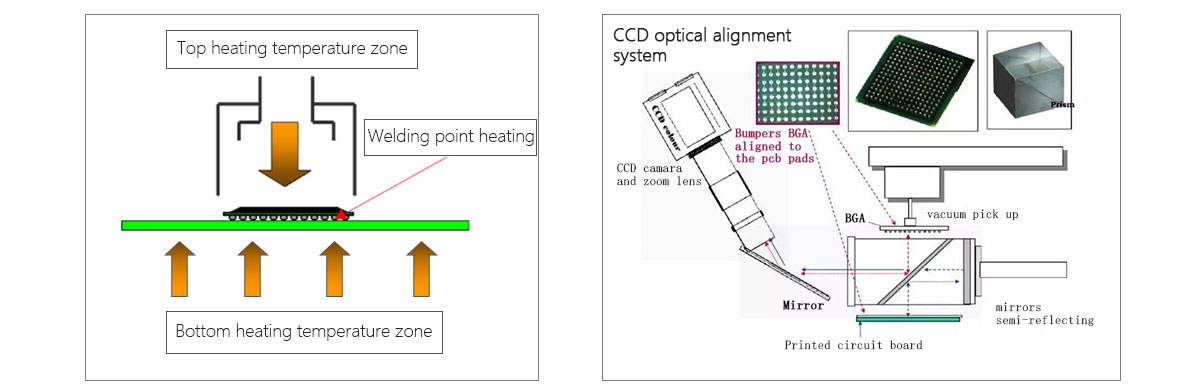

2.Heat the BGA chip through the top temperature zone, bottom temperature zone, and preheating temperature zone to melt the solder joints at the bottom of the chip, and remove the chip from the circuit board;

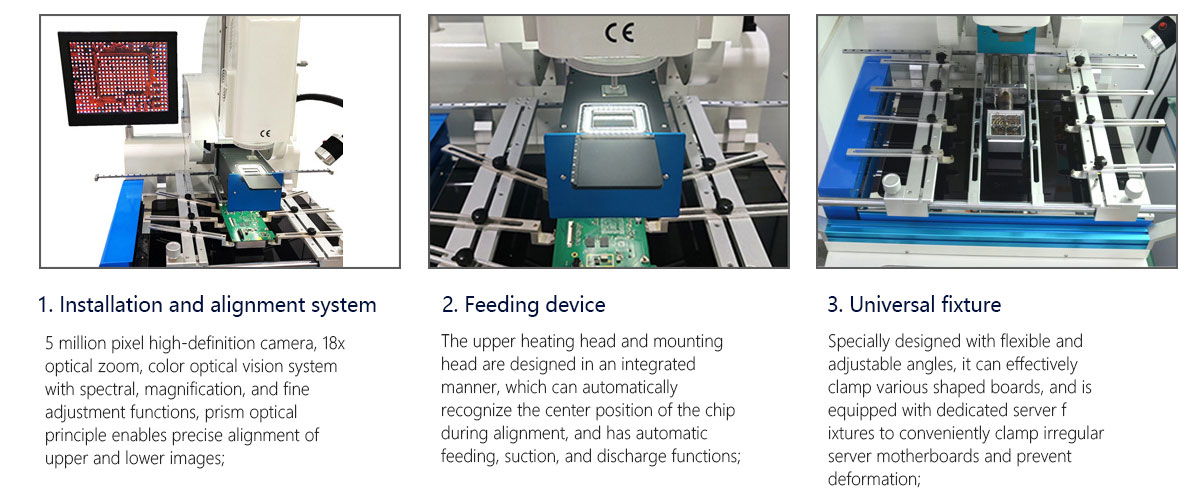

3.By using the CCD optical alignment system, the solder joints at the bottom of the chip and the solder joints on the circuit board are accurately aligned, and then the soldering is completed through automatic mounting;

Application scope:

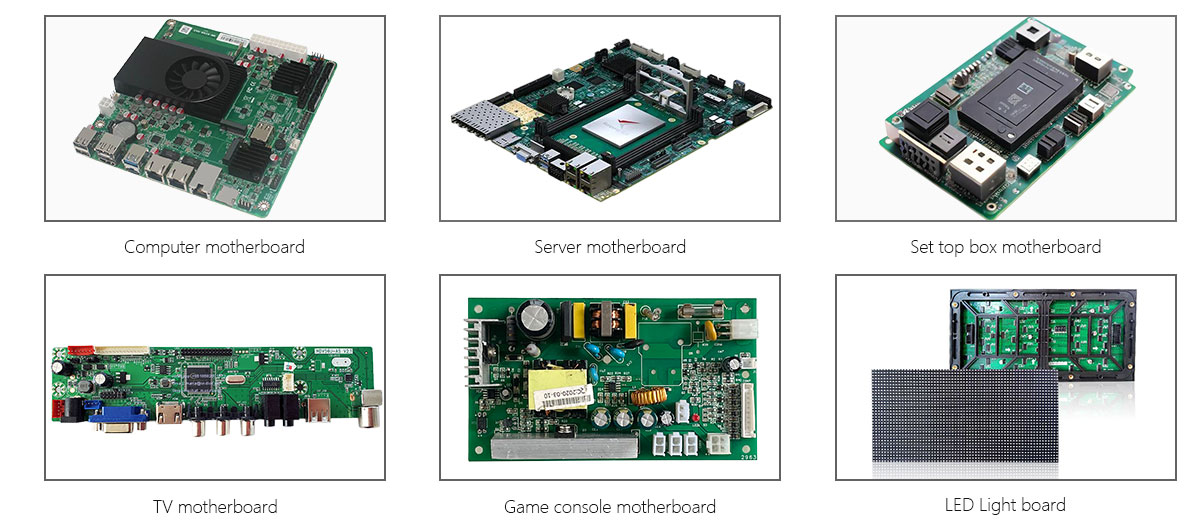

1.Suitable for repairing various types of circuit boards such as servers, game console motherboards, PC motherboards, SMT processing, motherboards, other communication motherboards, LCD TV motherboards, security products, tablets, intelligent terminals, etc;

2.Mainly targeting the repair of BGA/POP, PTH, WLESP, QFN, CHIP0201/01005, shielding frames/modules and other components on PCBA substrates;

Feature Highlights:

Other functional features:

1. Independent three temperature zones (upper temperature zone, lower temperature zone, infrared preheating zone), the upper and lower temperature zones can move synchronously and automatically reach any position within the bottom infrared preheating zone. The lower temperature zone can move up and down, supporting the PCB, and is automatically controlled by a motor. Realize that the PCB remains stationary on the fixture, and the upper and lower heating heads can move together to the target chip on the PCB;

2. The upper wind head adopts a hot air system, which heats up quickly, maintains a uniform temperature, and cools down quickly (with a sudden drop of 50-80 degrees during cooling), better meeting the process requirements of lead-free soldering. The lower heating zone adopts a mixture of infrared and hot air heating. Infrared directly acts on the heating area and conducts heat simultaneously with the hot air, which can compensate for each other's shortcomings and make the PCB heat up quickly (with a heating rate of 10 ℃/S) while maintaining uniform temperature;

3. The suction nozzle automatically recognizes the suction and mounting height, and the pressure can be controlled within a small range of 10 grams. It has zero pressure suction and mounting functions, suitable for smaller chips;

4. X/Y adopts a motor automatic control movement method, which makes alignment fast and convenient, and fully utilizes equipment space. It achieves large-area PCB repair with a relatively small equipment volume, and the maximum clamp size can reach 610x480mm, without any blind

spots for repair;

5. The machine automatically generates SMT standard temperature disassembly curves at different temperatures in different regions and environments, without the need for manual setting of machine curves. It can be used with or without experience, achieving machine intelligence;

6. The preheating platform, clamping device, and cooling system can move as a whole in the X direction, making PCB positioning and disassembly soldering safer and more convenient;

7. Unique bottom preheating platform, using excellent heating materials imported from Germany (infrared gold-plated light tube)+anti glare constant temperature glass (temperature resistant to 1800 ℃) with a preheating area of 500x420mm; The advantages of bright infrared heating tubes: fast heating, when the equipment is heated normally, there will not be a large temperature difference between the temperature around the PCB motherboard and the temperature at the location of the repaired chip, to ensure that the PCB motherboard will not deform or twist, which can better improve the soldering yield of the chip;

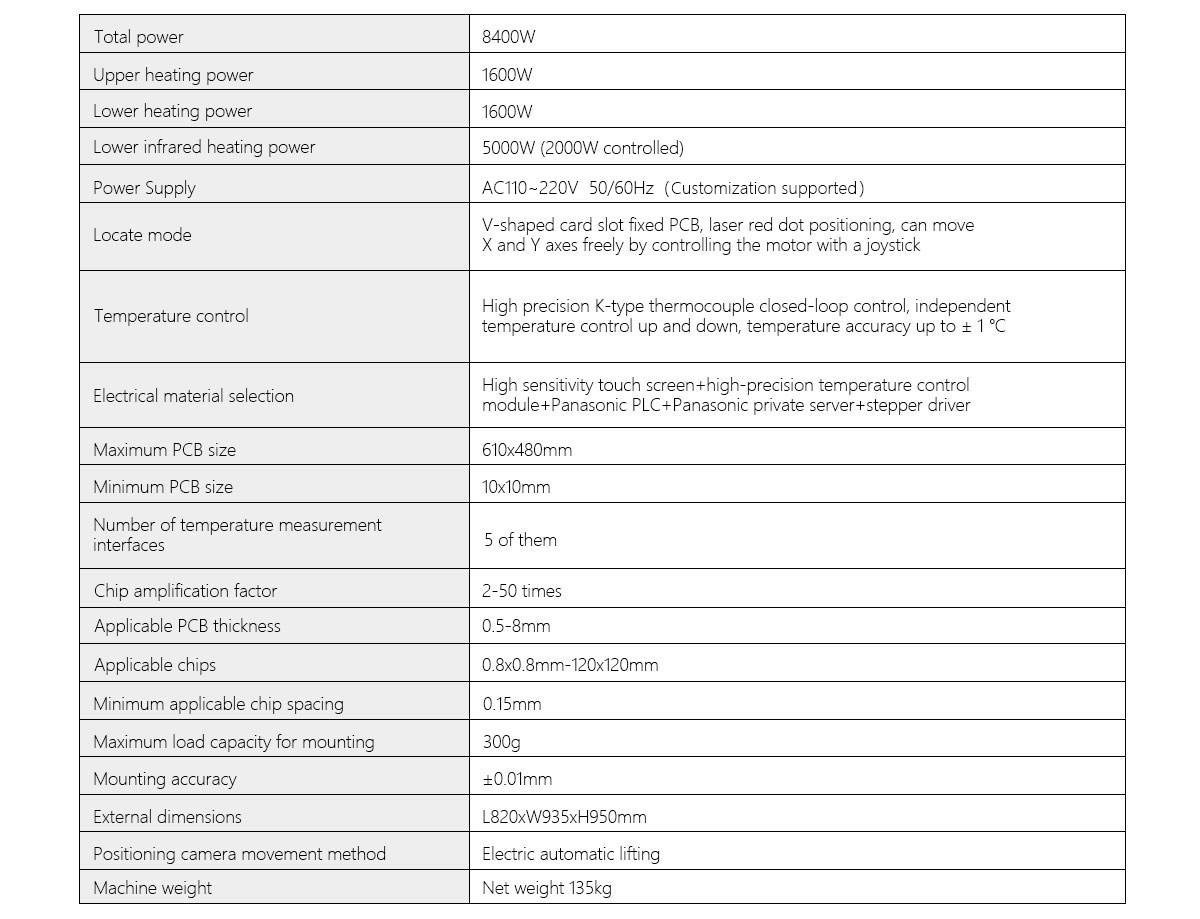

Equipment parameters:

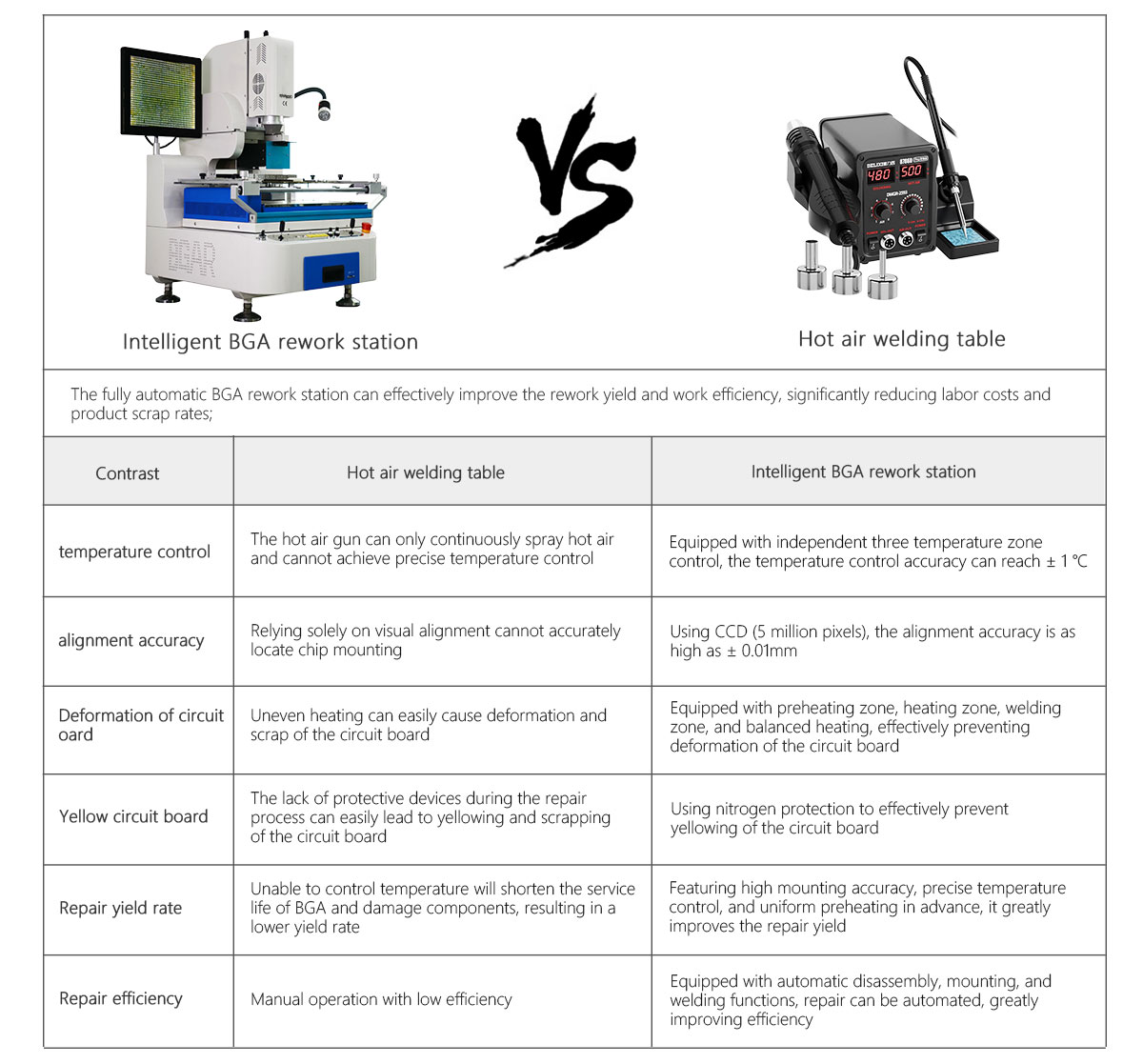

Why choose BGA rework station?