Application fields:

This model is suitable for high-precision chip or motherboard ball placement, wafer ball placement, etc., and can be applied to the high-repetitive positioning ball placement processing industry. Specific application scope:

(1) Supports BGA, QFN packaging, etc., with a minimum ball diameter of 0.2mm and a maximum ball diameter of 1.27mm.

(2) Various PCBA motherboards require precise soldering on circuit boards, small boards, with a minimum size of 2*2MM, and printing for objects up to 220*110 in size.

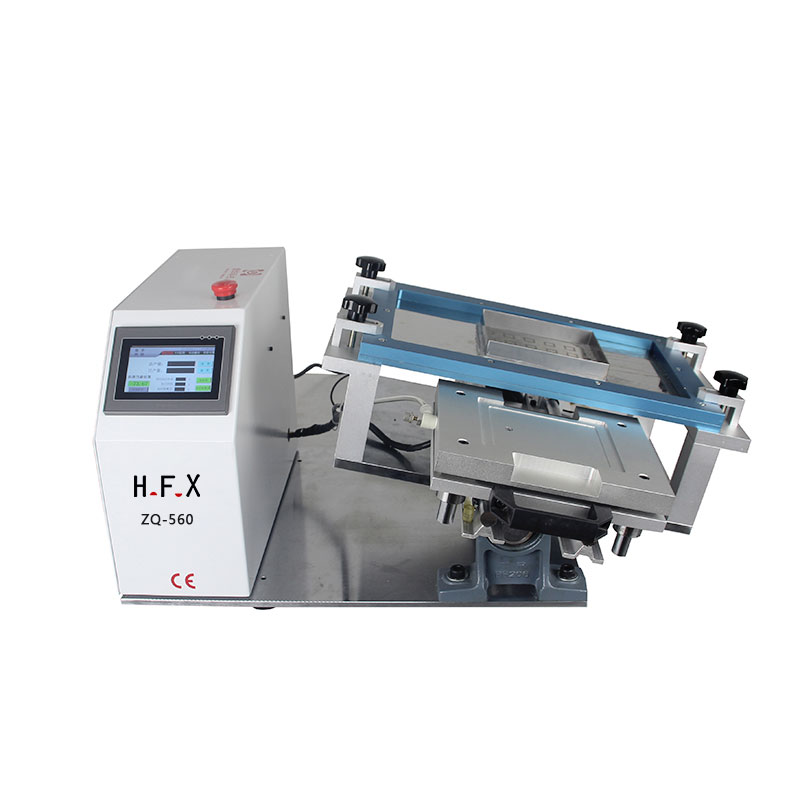

Product description:

1. The equipment is controlled by a stepper motor, ensuring stable up-and-down movement with a control accuracy of ±0.01mm;

2. It adopts a variable fixture slot, which can accommodate different BGA chips and is highly efficient;

3. Vacuum adsorption is used to further ensure the effect;

4. It exclusively adopts a touch screen human-machine interface, making operation simple and easy to learn;

5. The adjustable angle structure is adopted to better adapt to the human-machine principle.

Technical Specifications:

1. The ball placement machine utilizes an imported dual-guide rail system for repetitive shifting operations, coupled with a high-precision electric lifting

platform mechanism, ensuring that each positioning displacement is accurate and overlaps with the previous one (with an error margin of 0.01mm).

2. Control the separation between the mold and the steel mesh, with speed and travel distance allowing for flexible implementation of various demolding

methods. The quick-locking steel mesh screw facilitates the replacement of steel meshes of different specifications.

Technical parameters:

Repeatability positioning accuracy: ±12μM

Printing accuracy: ±15μM

Cycle time: <30S (excluding chip mounting time)

This machine adopts a positioning column method for rapid alignment and supports communication interface: USB2.0

Feeding speed: manual

Demolding speed: 0.1~15MM/sec

Planting speed: 3000 PCS/H (related to the design of the template)

Power Supply: AC110-220, 50/60HZ (Customization supported)

Compressed air: Equipped with a vacuum pump or vacuum generator

Working environment temperature: -20℃~+45℃

Working environment humidity: 30~60%

Machine weight: 30KG

Equipment dimensions: Length: 580mm, Width: 610mm, Height: 430mm (For customized models, please refer to the actual product)

Operating system: HMI + PLC

Specification of the tool steel mesh template used:

Base size: 240*160mm (other sizes can be customized upon request, with a maximum size of 400*400)

Base thickness: 30mm

Template size: 120*160mm (other sizes can be customized upon request, with a maximum size of 380*380)

Template thickness: 3-5mm (customizable according to customer requirements)

Maximum weight of base: 5KG

Steel mesh size range: 280*420mm (other specifications can be customized up to MAX420*420MM)

Steel mesh thickness: 0.08~0.3mm

Chip or template fixation: positioning frame and vacuum adsorption