PCBA production line solution

The SMT assembly line operates from the loader to the unloader, with full automation throughout the entire process. Everything starts with loading and cleaning the boards. The printer accurately adds solder paste. The JUKI machine quickly mounts the parts. The reflow oven ensures the solder is secure. The AOI detects the quality of the soldering. The NG/OK unloader is responsible for sorting the boards. This smooth process enhances speed and reduces errors. It reduces production costs and improves production efficiency.

Feature

1. Automated workflow

The SMT assembly line operates from the loader to the unloader, with full automation throughout the entire process. Everything starts with loading and cleaning the boards. The printer accurately adds solder paste. The JUKI machine quickly mounts components. The reflow oven ensures the solder is secure. AOI is used for quality inspection. The NG/OK unloader is responsible for sorting the boards. This smooth process enhances speed and reduces errors. It reduces production costs and improves production efficiency.

2. JUKI Placement Technology

The JUKI selection and installation in our PCBA production line ensure precision. It can quickly mount tiny components onto PCBs. Its high speed is suitable for large-scale production. The machine coordinates with the conveyor to achieve a fully automated process. It supports circuit boards ranging from small to large. This technology reduces defects in LED or mobile phone components.

3. Reflow oven efficiency

The reflow oven within the production line can evenly heat the circuit board. It can strongly solder components without causing damage. The advantage is that the temperature is easy to control, and oxidation can be avoided during the soldering process, making manufacturing costs easier to manage. This step is suitable for turnkey PCBA production lines to ensure reliable output. Low energy consumption saves costs.

4. Inspection and testing

AOI scans the circuit board after soldering. It can identify missing components. SPI detects the thickness, area, and volume of solder paste on the printed circuit board before placement. NG boards are automatically marked and sorted out. This ensures high quality in the automatic LED bulb assembly line.

5. Flexible production line configuration

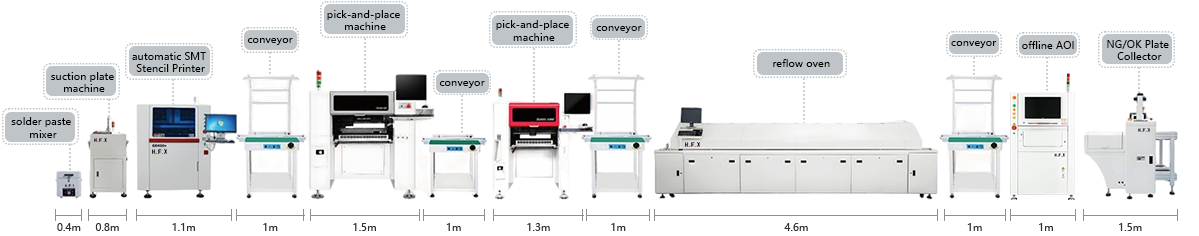

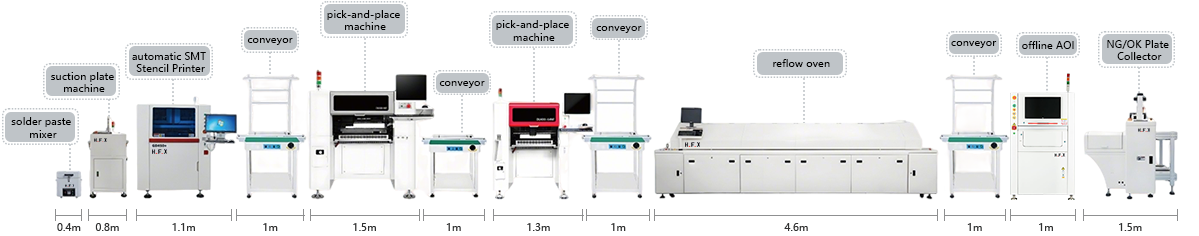

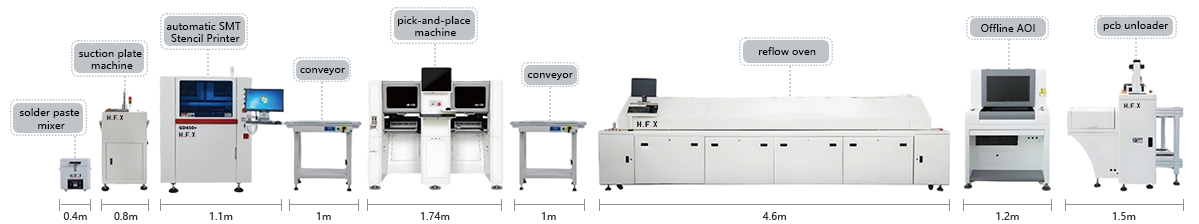

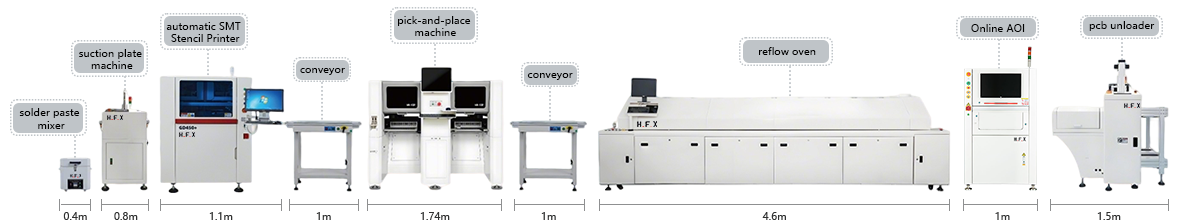

Choose between semi-automatic or fully automatic PCBA production lines. Semi-automatic is suitable for small items, such as light bulbs. Fully automatic is responsible for automotive electronic equipment. The layout diagram helps plan the space. We will flexibly configure the production line equipment according to your factory needs.

Specification

| Category | Projects | Details |

Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

SMT Line Equipment List

H.F.X High Quality PCBA Production Line features advanced equipment for efficient and precise PCB assembly. The fully automated SMT line includes a loader, an auto printer for accurate solder paste application, a pick-and-place machine for precise component placement, a reflow oven for reliable soldering, and an AOI system for thorough defect inspection. This High Quality PCBA Production Line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting diverse industry requirements.

| Product Name | Purpose in SMT Line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

Certifications and Standards

H.F.X holds CE for safety compliance. RoHS ensures no harmful materials. ISO9001 manages quality processes. Patents protect our innovations. These prove reliable PCBA Production Line.