Features

1. Innovative side illuminated detection technology

Adopting horizontal X-ray penetration scanning, it perfectly solves the limitations of traditional top illuminated equipment in detecting bottled beverages (liquid level bubble interference) and tin cans (metal lid obstruction).

Specially optimized optical path design ensures no blind spot scanning for high filling liquid level products (such as beverages, sauces) and metal packaging (such as cans), with higher detection sensitivity.

2. Ultra high speed detection and precise elimination

The detection speed is up to 30000 bottles/hour (standard operating condition for 500ml PET bottles), equipped with a high-performance servo removal system to ensure precise separation of defective products, with no omissions or errors.

Can adapt to various packaging types (glass bottles, metal cans, plastic containers) to meet the needs of high-speed production lines.

3. Industry leading hardware configuration

X-ray source: VJ 350W high-frequency constant voltage light source from the United States, stable and reliable, with a lifespan of over 20000 hours, suitable for testing products with different densities.

Detector: Finnish DT 0.2mm high-resolution linear array detector, capable of detecting foreign objects as small as 0.3mm (Fe sphere equivalent), ensuring high-precision detection.

Single light source optimized structure: While ensuring detection accuracy, it reduces energy consumption and maintenance costs, and improves the long-term stability of equipment operation.

Technical Specifications

| Project | Technical indicators |

| Detection speed | Up to 500 bottles per minute (customizable) |

| Detection accuracy | ≤ 0.3mm (Fe ball equivalent) |

| X-ray light source | US VJ 350W, lateral horizontal irradiation |

| Detector | Finland DT 0.2mm high resolution |

| Remove system | High response pneumatic removal with an accuracy of ± 1mm |

| Protection safety | Lead curtain shielding, radiation leakage<1 μ Sv/h |

| Software features | Multi product preset, data recording, real-time alarm |

Summary of Equipment Advantages

✅ Side illuminated design - more suitable for blind spot detection of bottled beverages and metal cans.

✅ Ultra high detection speed -500 bottles/minute, meeting the needs of high-speed production lines.

✅ Top hardware configuration - American VJ light source+Finnish DT detector, ensuring stability and accuracy.

✅ Intelligent removal system - high-precision pneumatic removal, 100% separation of defective products.

✅ Low maintenance cost - single light source structure, energy-saving and durable.

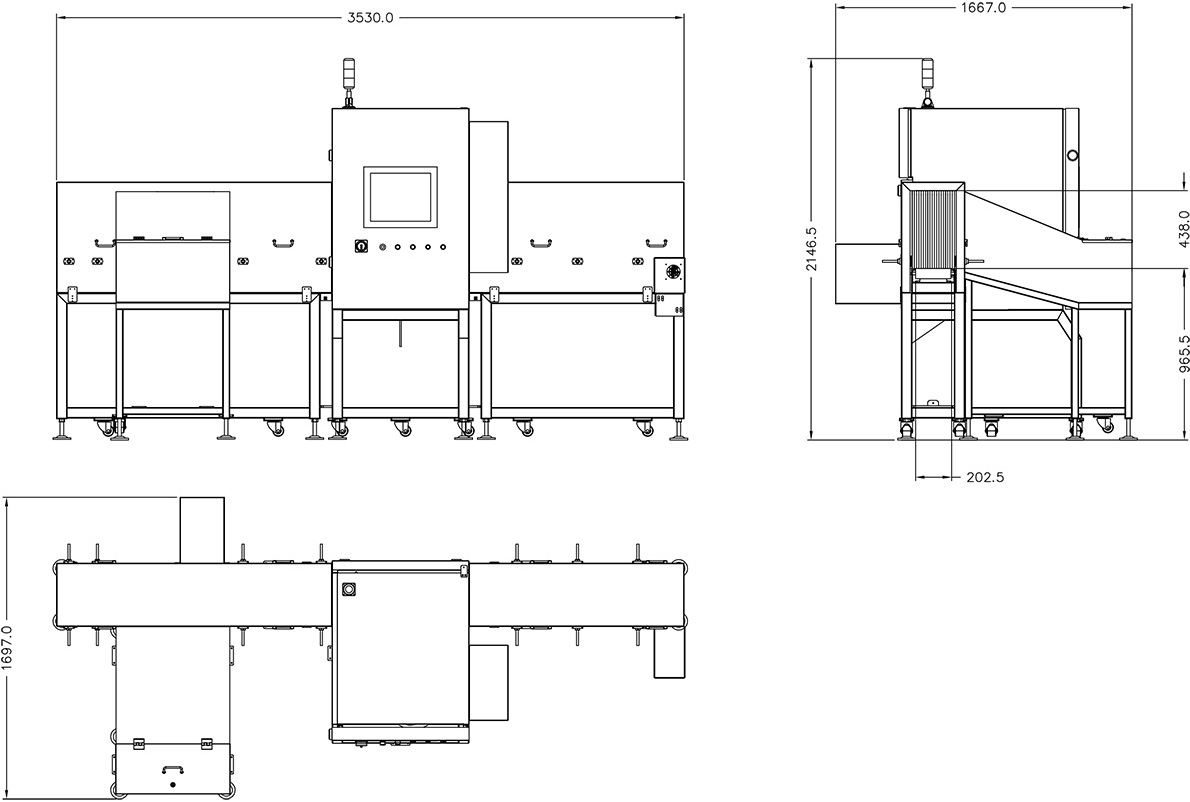

Device dimensions