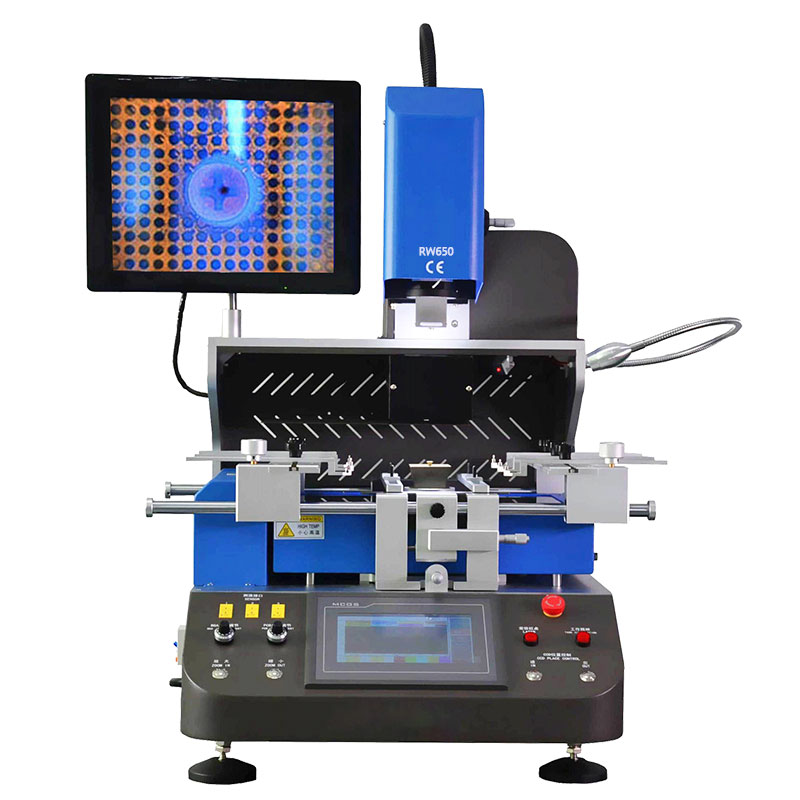

Equipment principle:

1.Based on operations such as heating, removing, cleaning, repositioning, and soldering BGA chips, to achieve repair and replacement of BGA packaging;

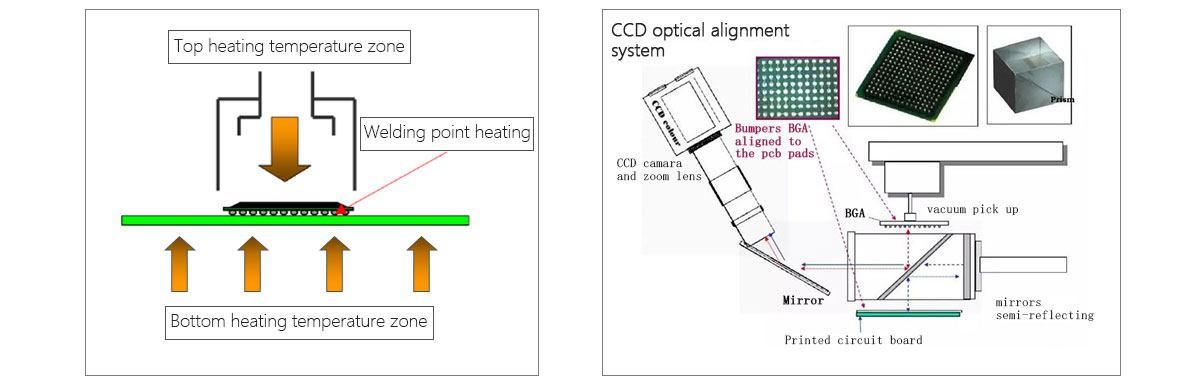

2.Heat the BGA chip through the top temperature zone, bottom temperature zone, and preheating temperature zone to melt the solder joints at the bottom of the chip, and remove the chip from the circuit board;

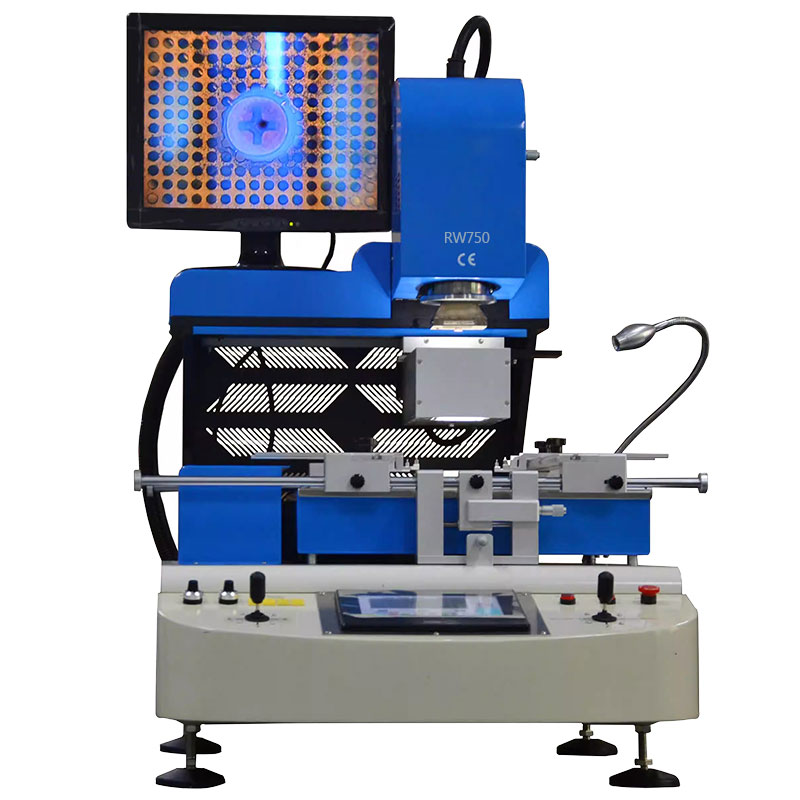

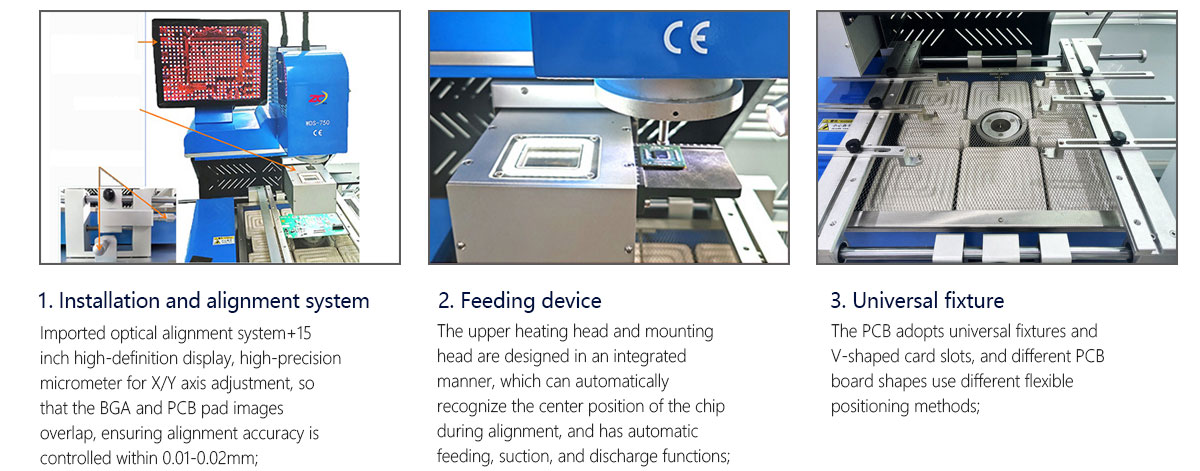

3.By using the CCD optical alignment system, the solder joints at the bottom of the chip and the solder joints on the

circuit board are accurately aligned, and then the soldering is completed through automatic mounting;

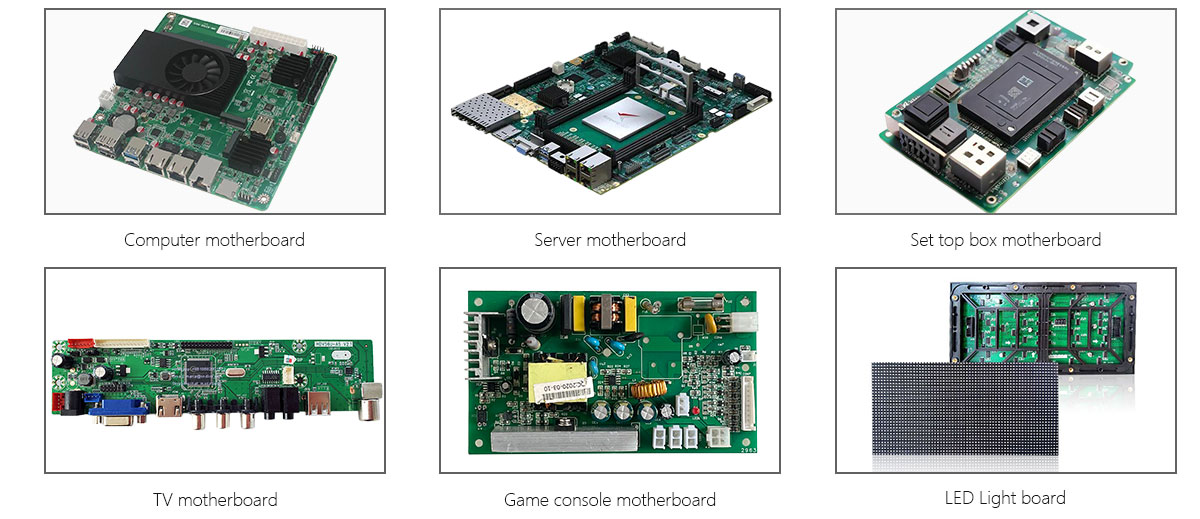

Application scope:

1.Suitable for repairing various types of circuit boards such as servers, game console motherboards, PC motherboards, SMT processing, motherboards, other communication motherboards, LCD TV motherboards, security products, tablets, intelligent terminals, etc;

2.Mainly targeting the repair of BGA/POP, PTH, WLESP, QFN, CHIP0201/01005, shielding frames/modules and other components on PCBA substrates;

Feature Highlights:

Other functional features:

1. The machine adopts a touch screen human-machine interface, with heating time, heating temperature, heating speed, cooling time, advance alarm, vacuum time, etc. all set internally on the touch screen, making the operation intuitive, simple, and easy to use;

2. This machine adopts Panasonic PLC imported from Japan and Dalian Institute of Technology temperature control module for independent control, displaying three temperature curves at any time and four independent temperature measurement interfaces. It can accurately judge the

temperature of multiple points on the chip, thereby ensuring the welding yield of the chip;

3. Three temperature zones are heated independently, and each temperature zone can independently set the heating temperature, heating time, and heating slope. There are six heating temperature ranges, simulating the reflow soldering heating method, which can be set as preheating,

insulation, heating, welding, reflow soldering, and cooling;

4. This machine has automatic feeding, suction, and discharge functions, and can automatically identify the center position of the chip when aligning;

5. Multi functional mode selection, with four modes including welding, removal, mounting, and manual, which can achieve automatic and semi-automatic functions to better meet customers' various needs;

6. Select high-precision K-type thermocouple closed-loop control imported from the United States, combined with our company's unique heating method, to ensure that the welding temperature difference is within ± 1 ℃;

7. High automation and precision, completely avoiding human operation errors, can achieve the best results for lead-free processes and repair of double-layer BGA, QFN, QFP, capacitors, resistors and other components;

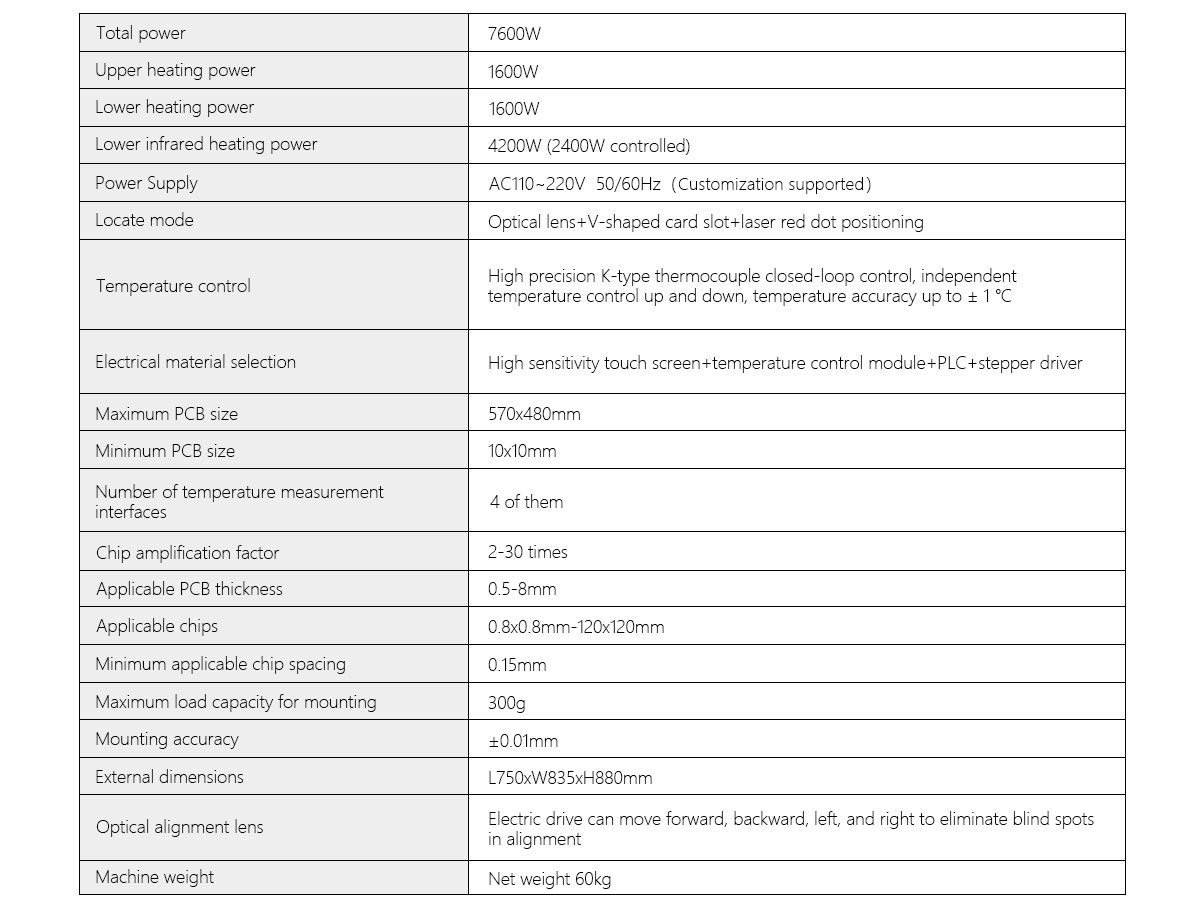

Equipment parameters:

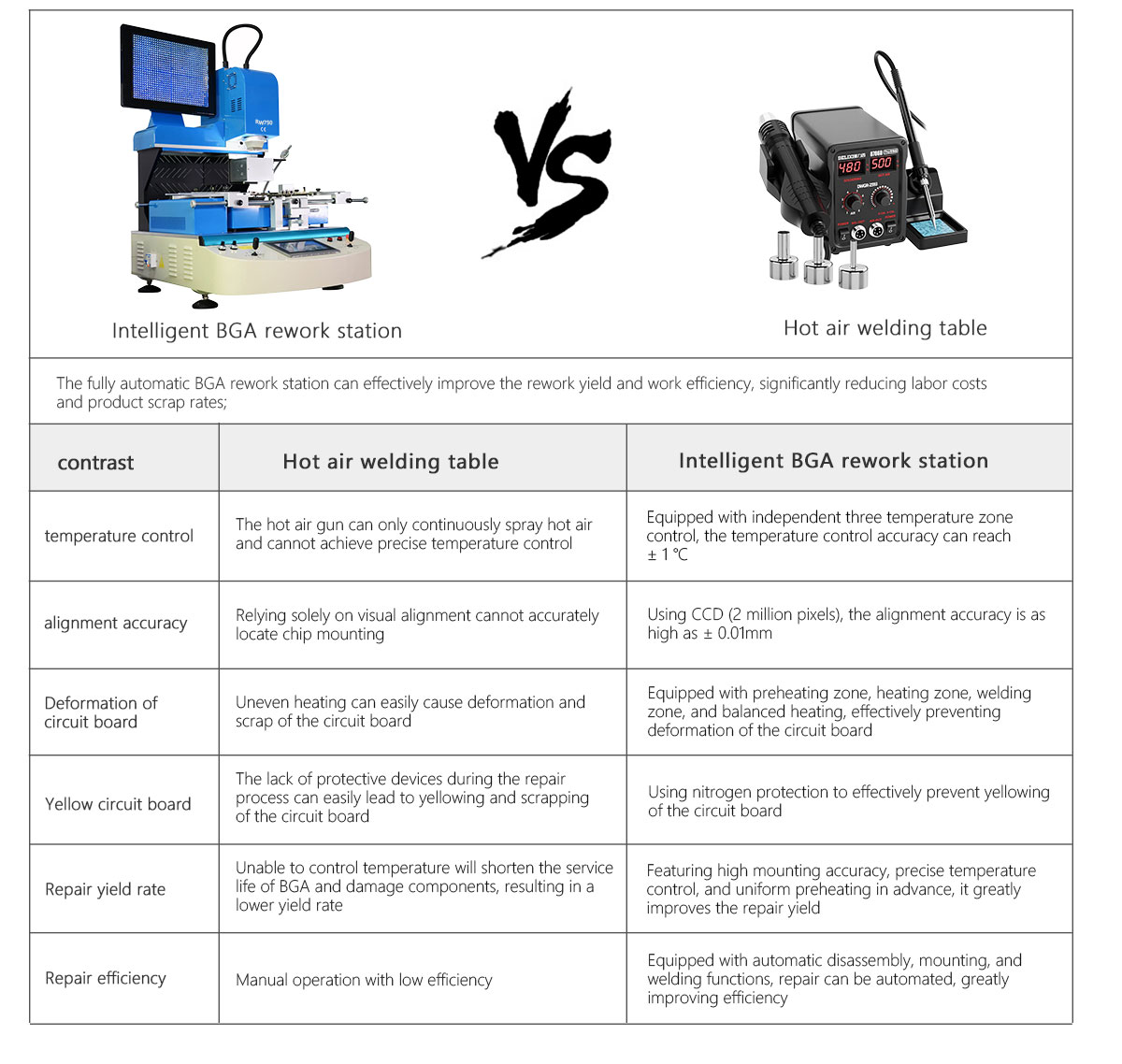

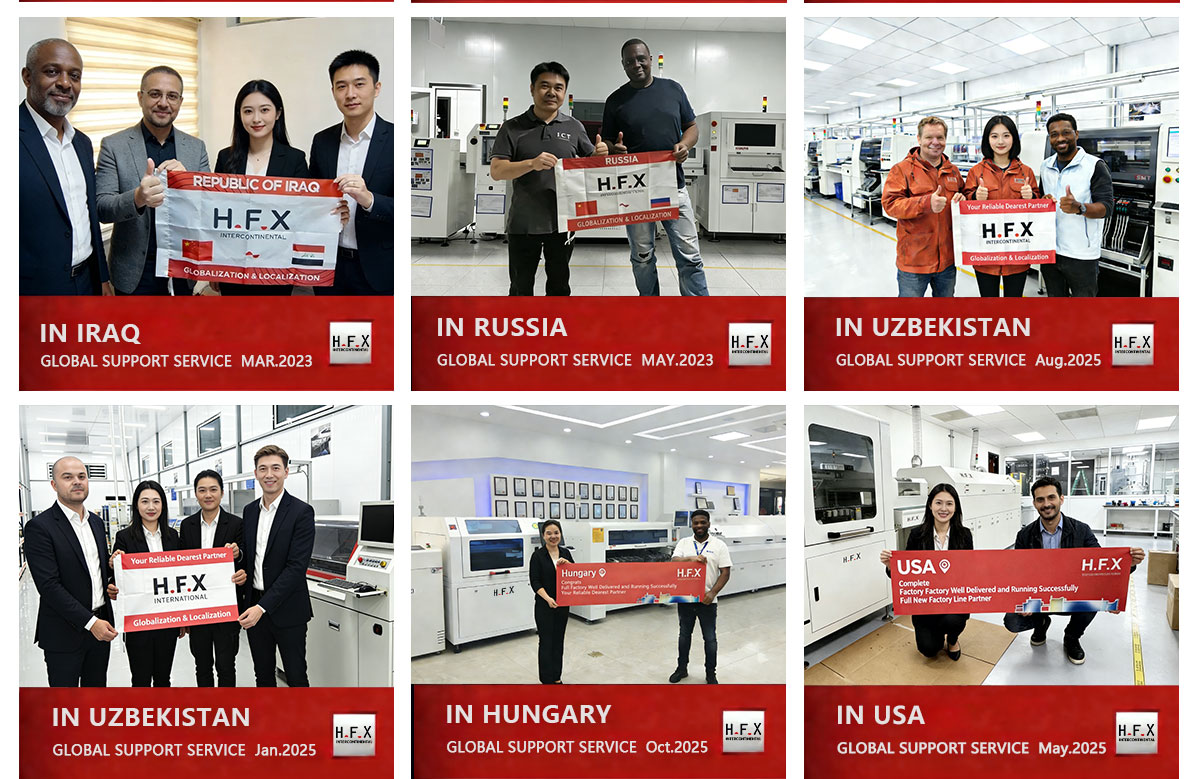

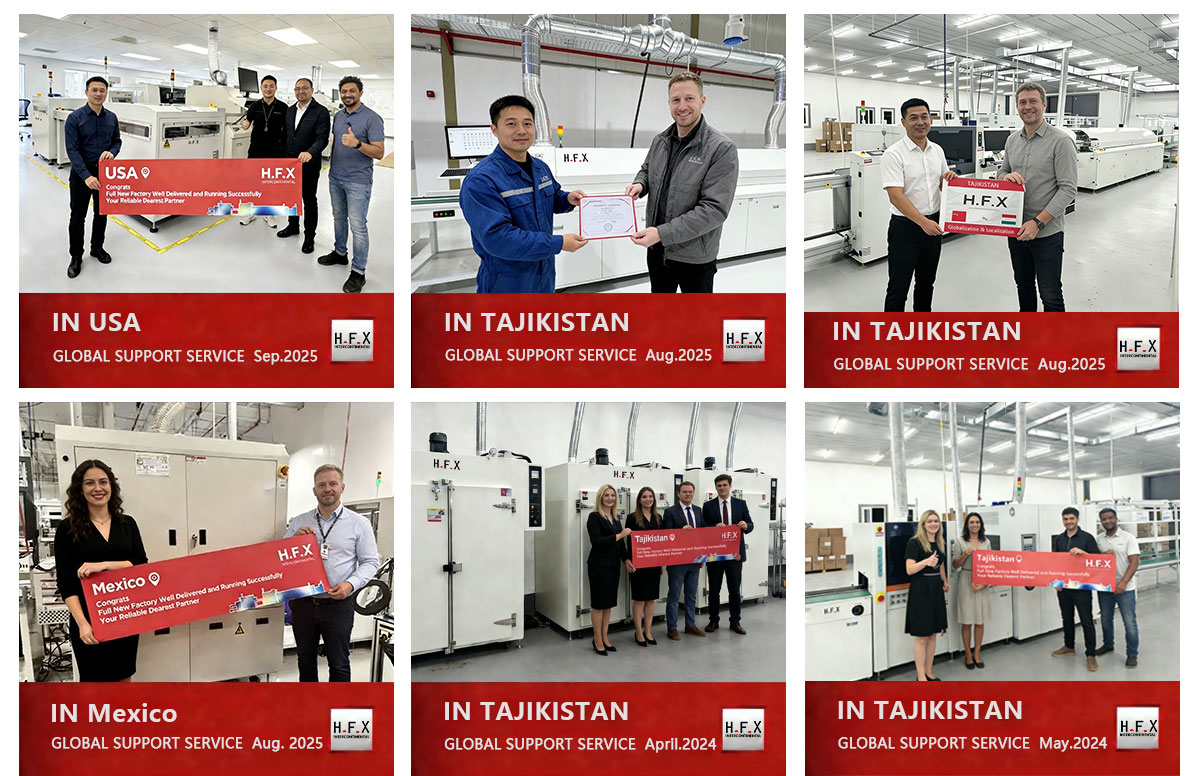

Why choose BGA rework station?