Product parameters:

| Model | Double-sided Projection Inline Machine / AI-400M |

| Camera | 12-megapixel industrial camera |

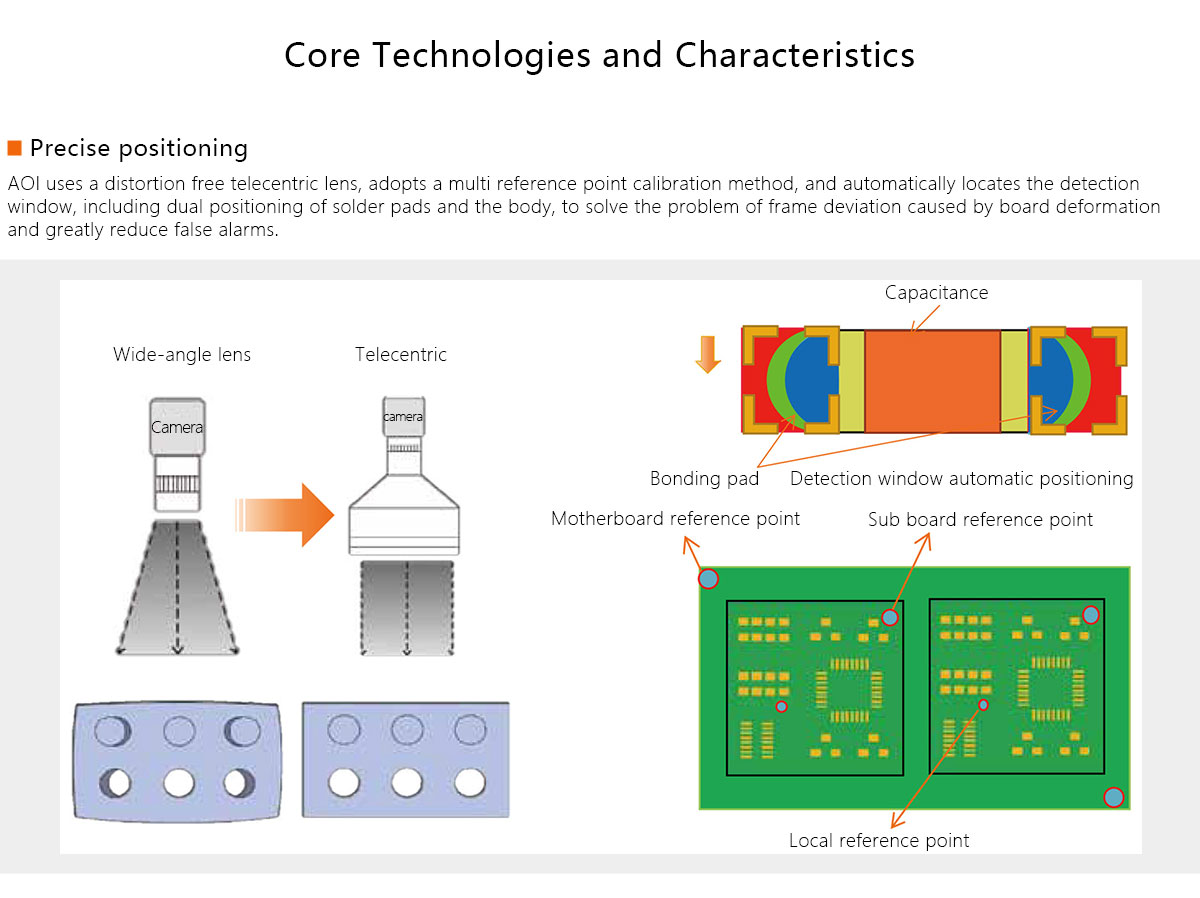

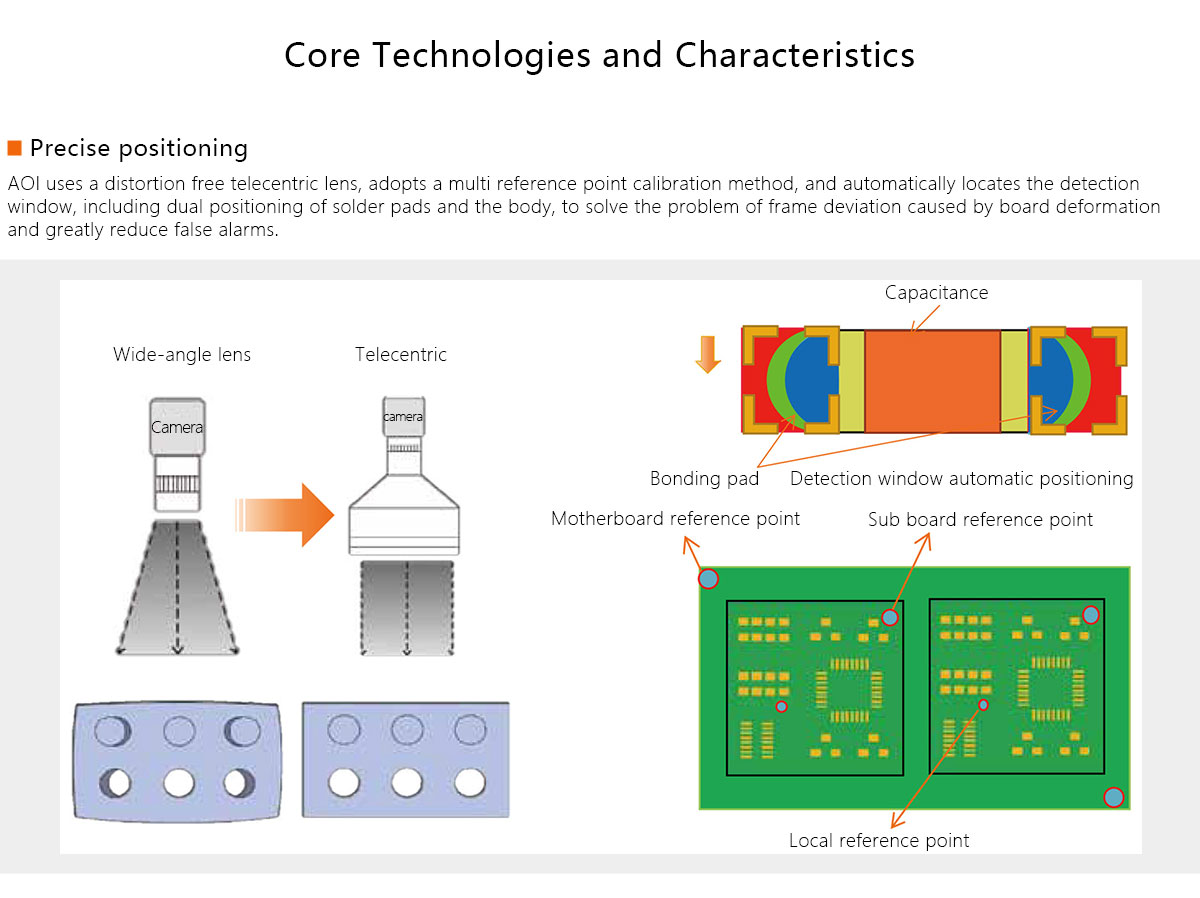

| Lens | Telecentric lens |

| Light source | RGB three-color light |

| Resolution | 16μm (optional 10μm/10μm as option) |

| FOV scope | 16μm:64*48mm 10μm:40*30mm |

| Size of detectable PCB | 510mm*460mm |

| PCB thickness scope | 0.3~5mm |

| Edge width | 3mm |

| Top/Bottom clear height | Ex-factory standard:TOP:50,BOT:30mm / Maximum adjustable height:TOP:50,BOT:50mm |

| Maximum PCB weight | 7KG |

| Inspection speed | 230~300ms/FOV |

| X, Y motion | Servo Motor |

| Operating system | Windows10 64bit |

| Power supply | AC110~220V, 50/60Hz(Customization supported) |

| Air pressure | 0.5Mpa |

| Track height | 900 ± 20mm (can be customized to 750 ± 20mm) |

| Machine weight | About 1300KG |

| Size | L1080*W1493*H1615mm |

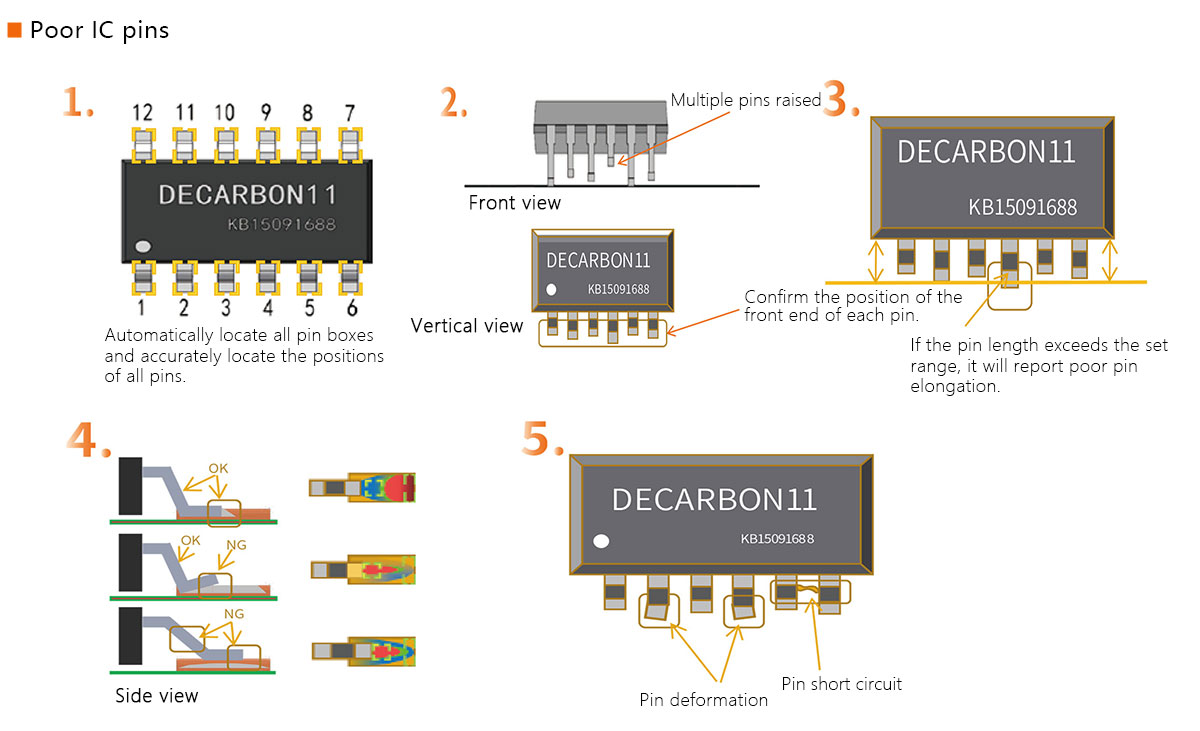

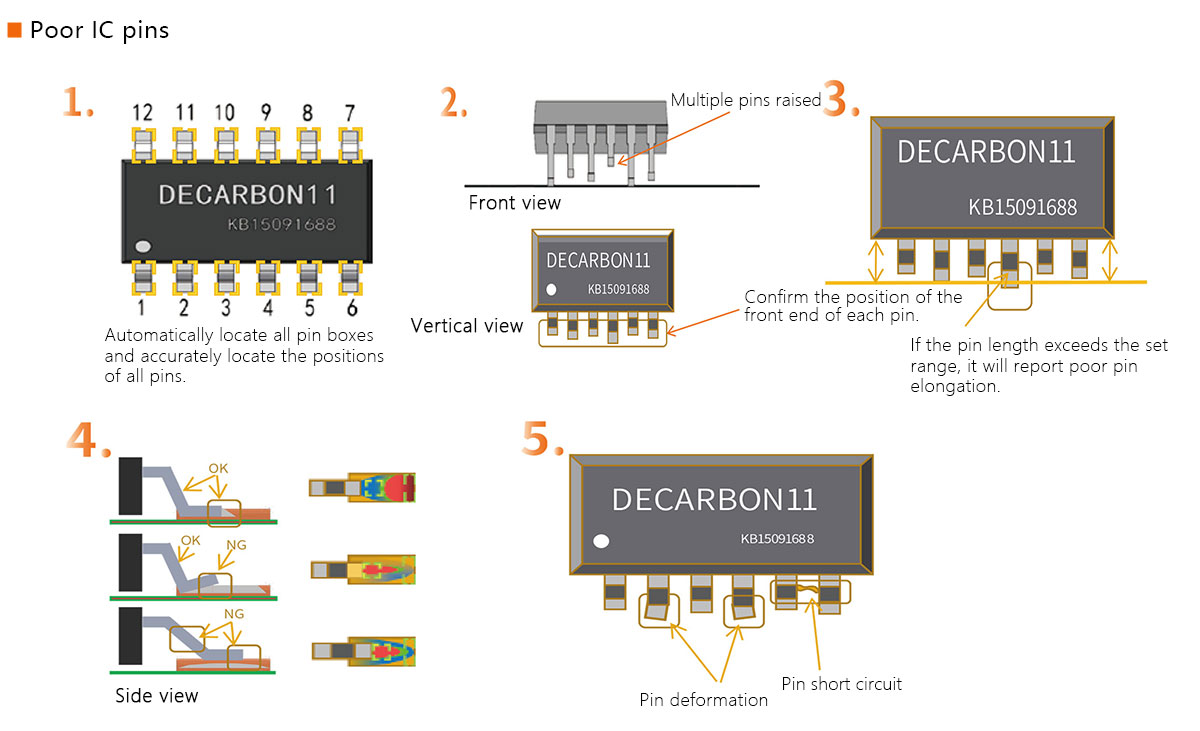

| SMT inspection items | Wrong parts, missing parts, reverse, offset, tombstoning, side stand, flip parts, damaged solder, short circuit, insufficient solder, false solder, missing solder, excessive glue, exposed copper,pin warpage, pin deformation |

| THT inspection items | Nonexistent solder, insufficient solder, excessive solder, cavity, short circuit, exposed copper, false solder, buried pins, solder ball, and contamination |

> Equipment can be customized according to customer needs

FAQ:

1.Will you provide on-site support?

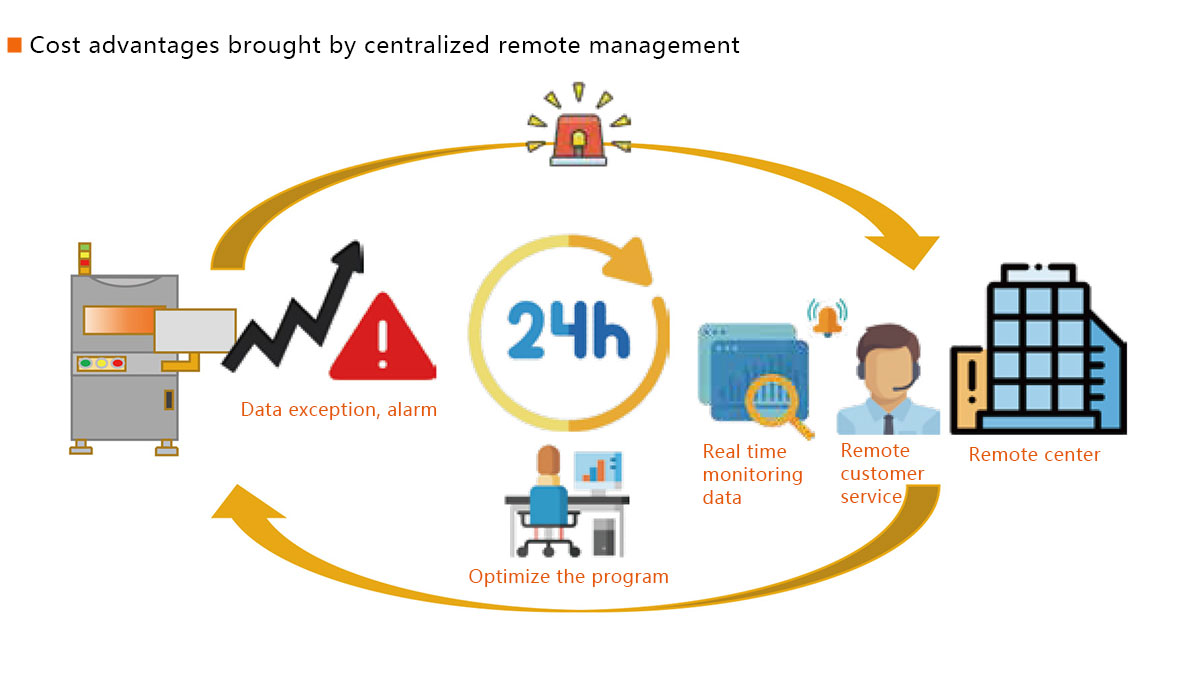

Our team of qualified and experienced engineers can provide on-site maintenance and repair support. You can use the online chat box Skype、Whatsapp、 Contact us by phone and email, and we are always on standby to assist you in resolving any issues.

2.Will any training be provided?

We provide a complete training program for all industrial testing equipment, maintenance equipment, picking and placing equipment, reflow soldering equipment, wave soldering, selective soldering equipment, solder paste printing machines, PCB splitting machines and other SMT production line equipment in our Shenzhen factory, and offer on-site training at the customer's location. Our plan aims to provide your engineers, technicians, and machine operators with the necessary knowledge to fully utilize the operation and maintenance of our machines.

3.Where can I buy spare parts?

You can visit our spare parts store to obtain the parts you need, which can be paid by bank transfer/PayPal/credit card. In addition, you can contact us to obtain parts and make payment through bank transfer.

H.F.X - Our Company

About H.F.X:

H.F.X is a leading provider of factory planning solutions and industrial inspection solutions. We have 4 wholly-owned factories that provide professional consulting and services to global customers. We have over 12 years of experience in electronic integrated solutions and industrial testing solutions. We not only provide a complete set of equipment, but also offer comprehensive technical support and services, and provide customers with more reasonable professional advice. We help many clients establish factories in LED, TV, mobile phone, DVB, EMS, and other industries around the world. We will establish factories in LED, TV, mobile phone, DVB, EMS, and other industries around the world. We have also obtained strict industry certifications such as CE, FDA, AERB, etc. Our products are exported to countries such as the United States, Germany, India, Singapore, Vietnam, Thailand, Canada, the United Kingdom, France, Italy, the Netherlands, Sweden, Mexico, Brazil, etc. We are trustworthy.

Exhibition:

For SMT factory setup and industrial non-destructive testing, we can provide you with:

1. We provide you with complete SMT solutions and industrial testing solutions

2. We Provide Core Technology With Our Equipments

3. We provide the most professional technical services

4. We have rich experience in establishing SMT factories and industrial testing

5. We can solve any problems related to SMT and industrial testing

H. F.X-AI-400M | Double sided online 2D automatic optical inspection equipment