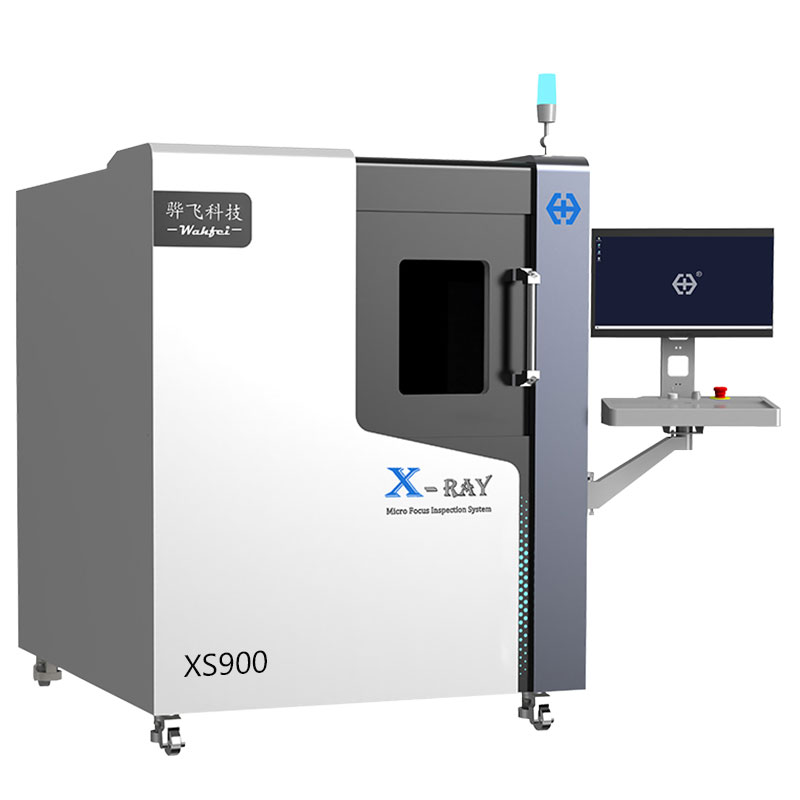

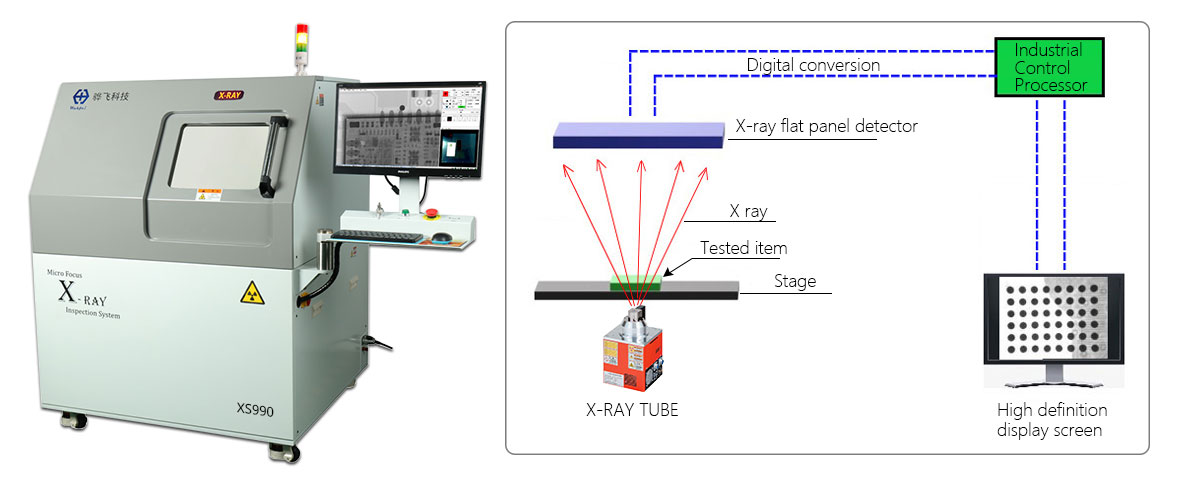

Equipment principle:

1.Non destructive testing of the internal structure of the object being tested by utilizing the penetrability of X-rays and the absorption and scattering characteristics of substances towards X-rays;

2.The X-rays attenuated by the object reach the high-resolution image flat panel detector and undergo digital conversion to form a high-definition two-dimensional grayscale image;

3.The data processing system processes and analyzes images to accurately determine whether there are defects, foreign objects, structural abnormalities, and other adverse issues inside the object;

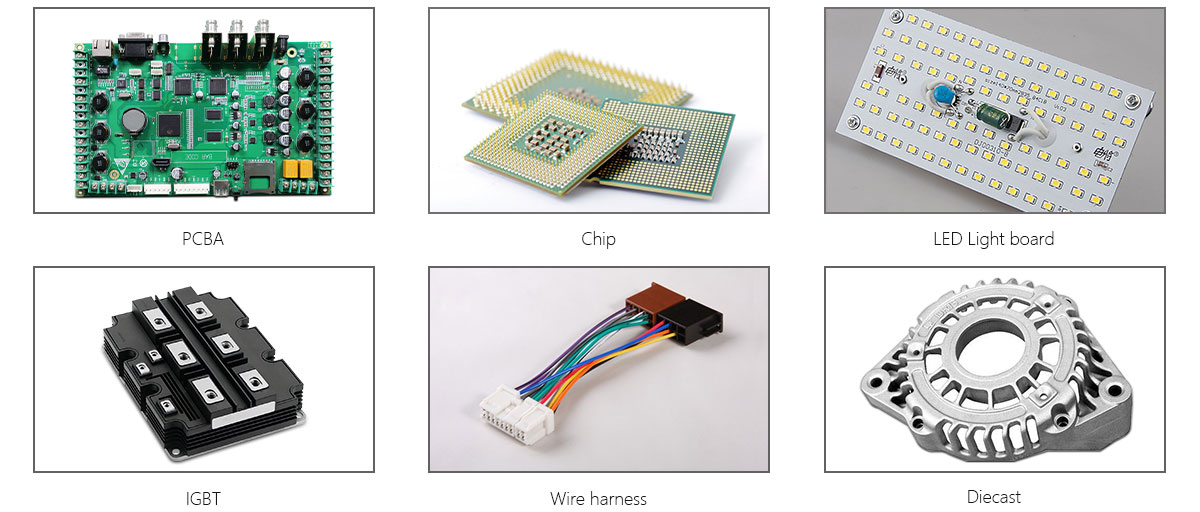

Application scope:

1.Mainly used in fields such as automotive electronics, energy electronics, home appliance electronics, consumer electronics, semiconductors, die-casting, etc;

2.Suitable for testing SMT mounting, BGA solder joints, packaged devices, semiconductor components, precision metal castings, injection molded products, etc;

3.Suitable for PCBA, chips LED、IGBT、 Wires, sensors, fuses, QFNs, MOSFETs FPC、 Non destructive testing of new energy lithium batteries, power cords, diodes, capacitors, automotive parts, aviation parts, etc;

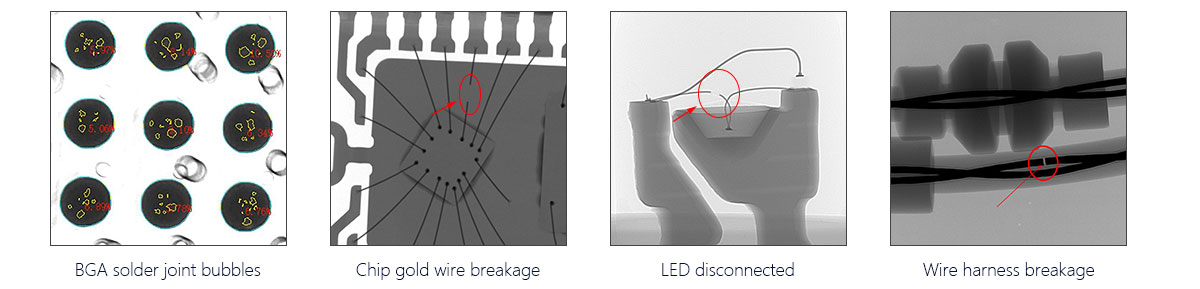

Test case:

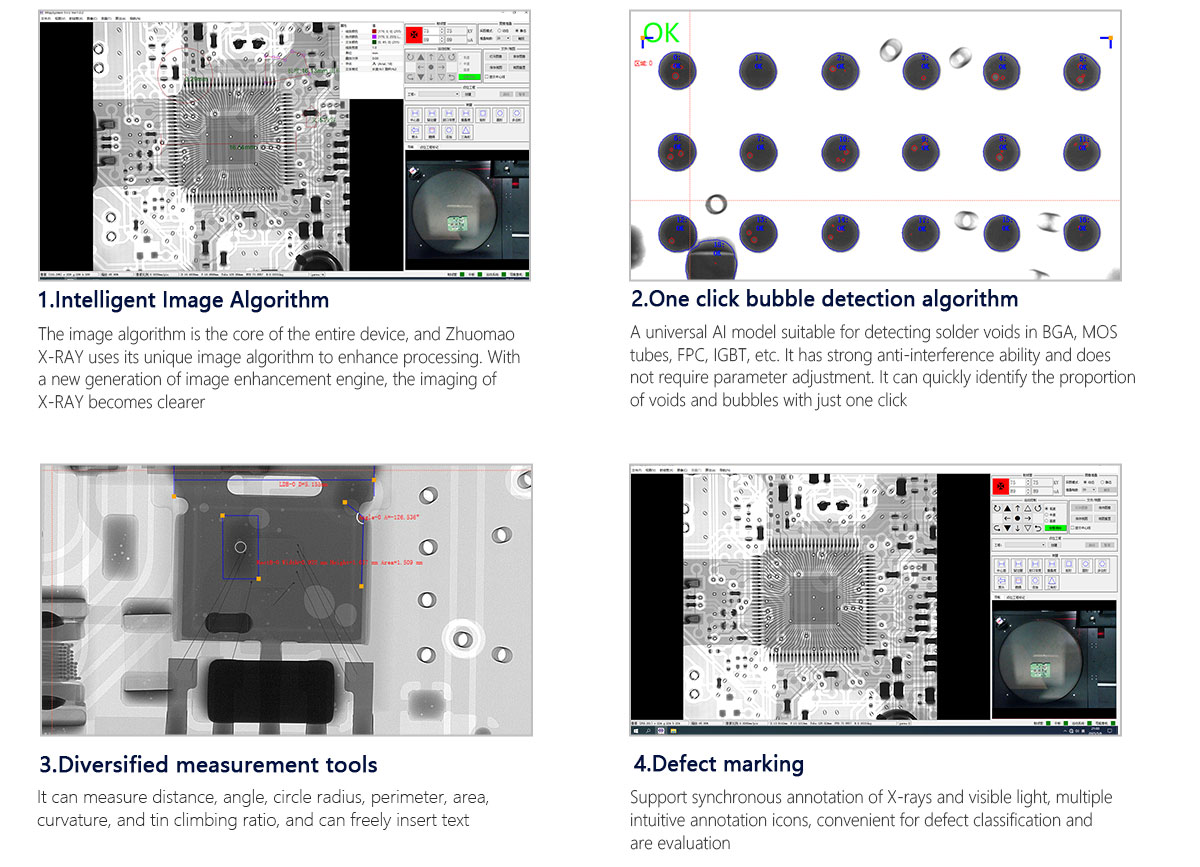

Functional Features:

Other features:

1.The device software is easy to operate, quickly identifying target defects, and requires two hours of training to get started;

2. High voltage, high resolution, and high magnification to obtain the best detection image;

3. Equipped with innovative self-developed intelligent detection software, new image enhancement processing, and preset filter algorithms;

4. CNC automated detection, automatic identification of good and defective products, and automatic production of inspection reports, with higher detection efficiency;

5. Multi angle analysis of internal structural defects of objects, one click opening and closing of doors, automatic centering display, and automatic following;

6. AI intelligent detection algorithms can be customized according to users' actual needs;

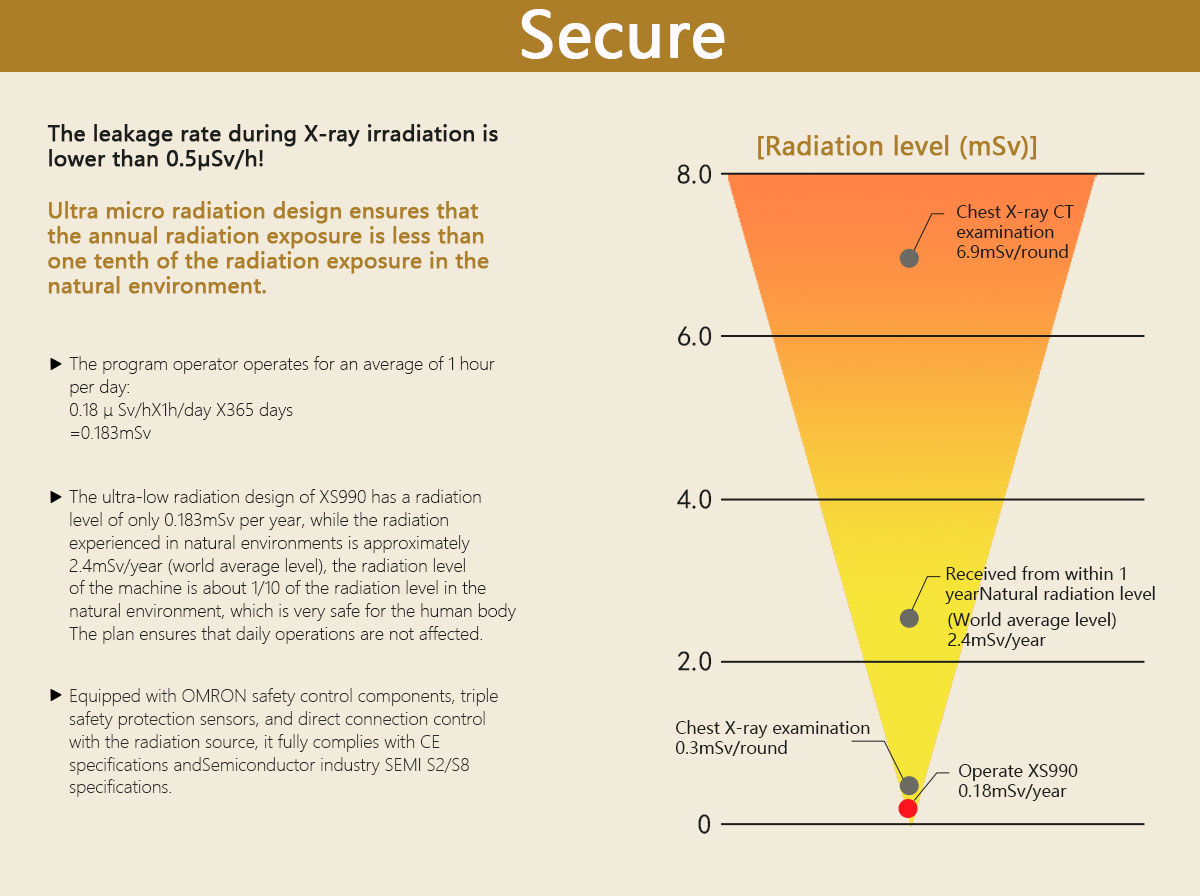

7. Real time monitoring of radiation values, safety interlock, automatic shutdown of radiation sources in idle state, and other multiple protections;

8. Optional 360 ° rotating stage for easy detection of product defects in all directions;

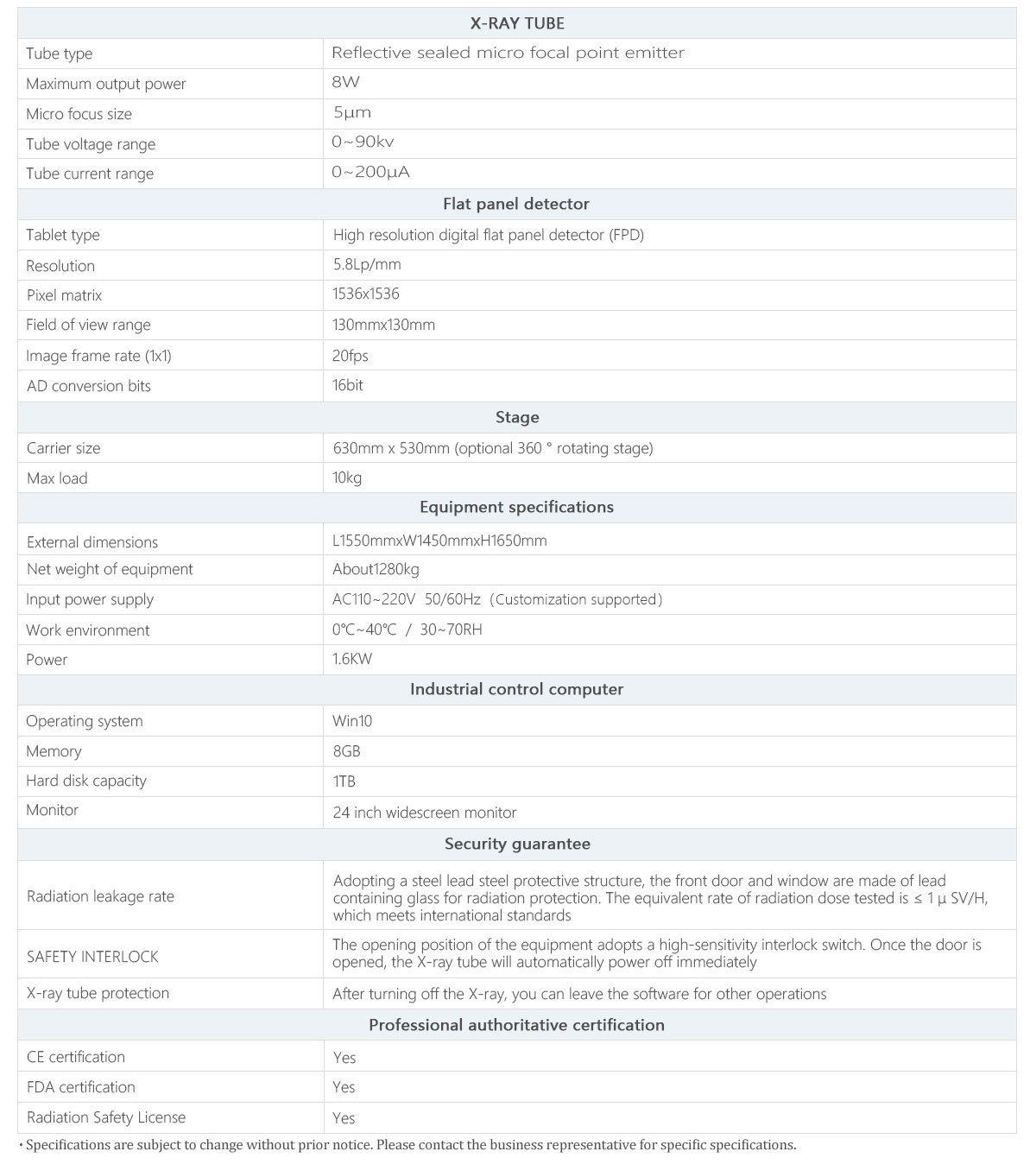

Technical Parameter:

Detection effect: