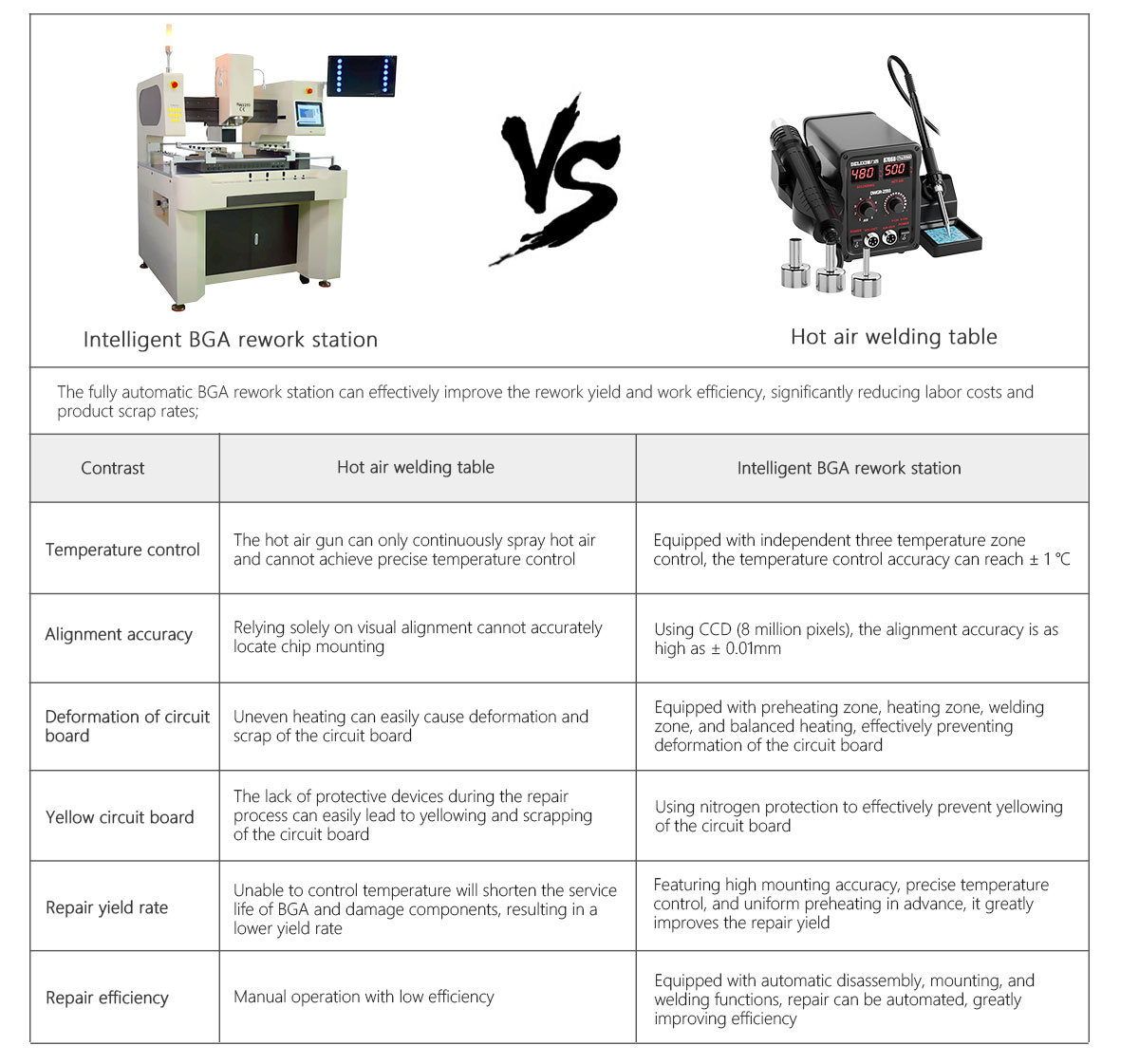

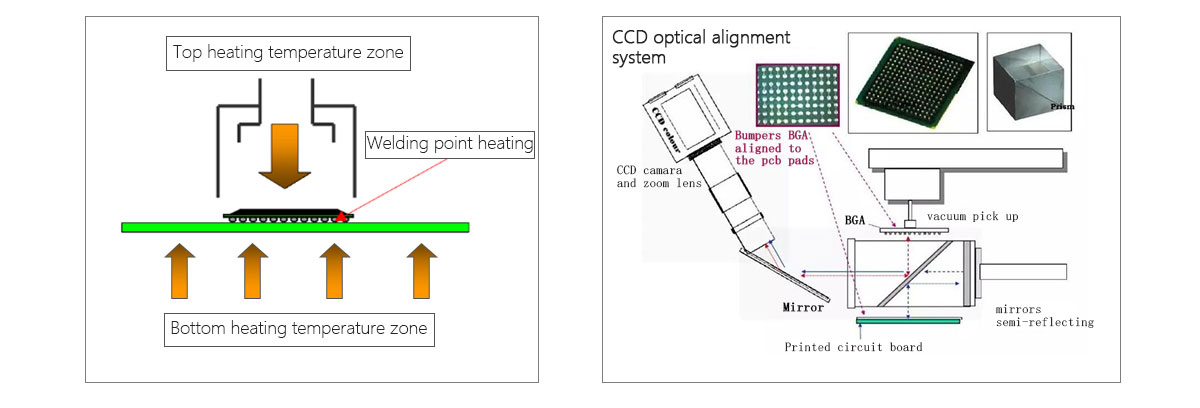

Equipment principle:

1.Based on operations such as heating, removing, cleaning, repositioning, and soldering BGA chips, to achieve repair and replacement of BGA packaging;

2.Heat the BGA chip through the top temperature zone, bottom temperature zone, and preheating temperature zone to melt the solder joints at the bottom of the chip, and remove the chip from the circuit board;

3.By using the CCD optical alignment system, the solder joints at the bottom of the chip and the solder joints on the circuit board are accurately aligned, and then the soldering is completed through automatic mounting;

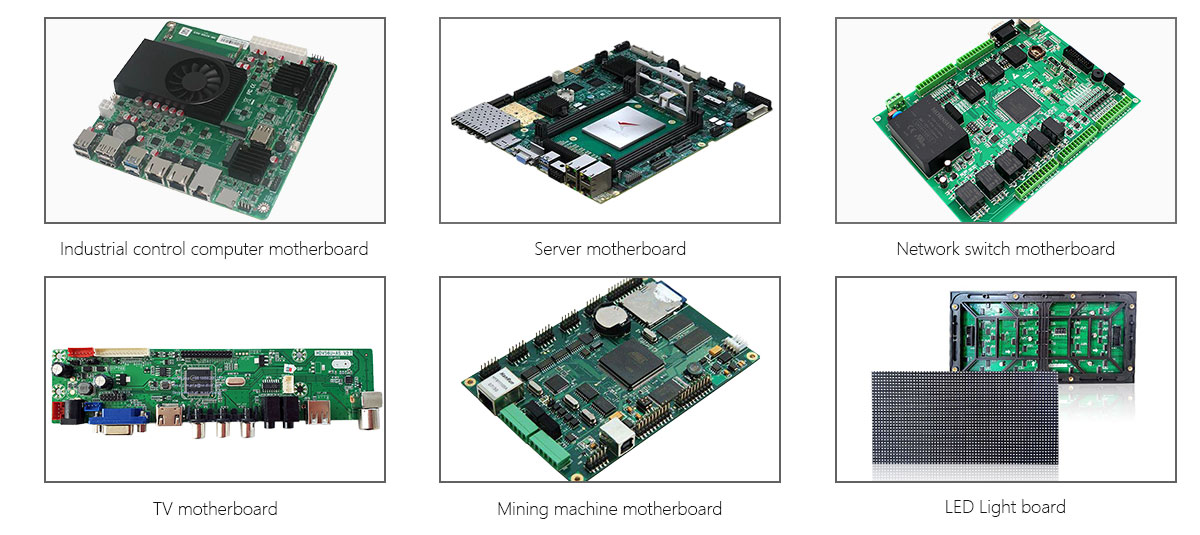

Application scope:

1.Suitable for repairing various types of circuit boards such as servers, game console motherboards, PC motherboards, SMT processing, motherboards, other communication motherboards, LCD TV motherboards, security products, tablets, intelligent terminals, etc;

2.Mainly targeting the repair of BGA/POP, PTH, WLESP, QFN, CHIP0201/01005, shielding frames/modules and other components on PCBA substrates;

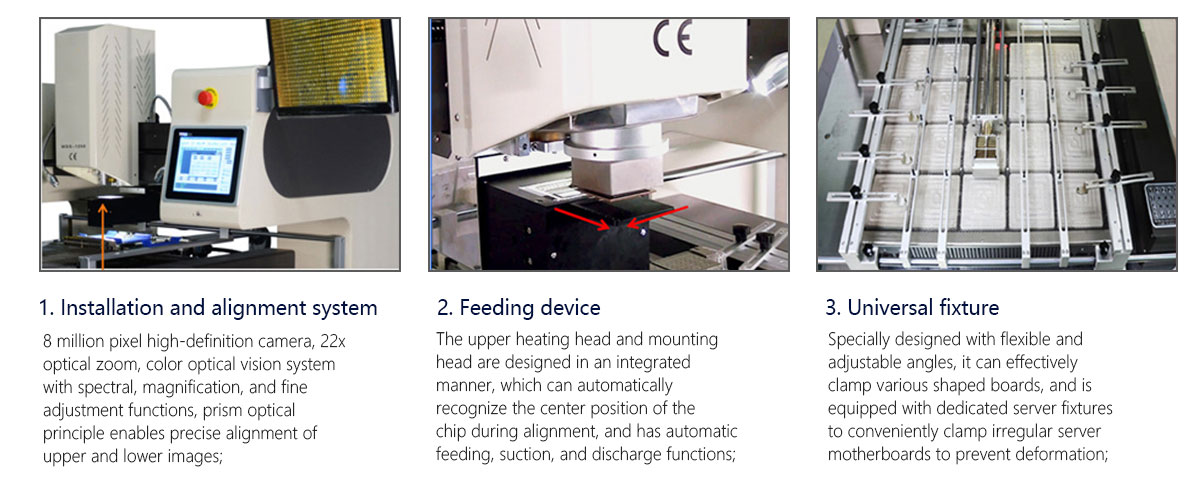

Feature Highlights:

Other functional features:

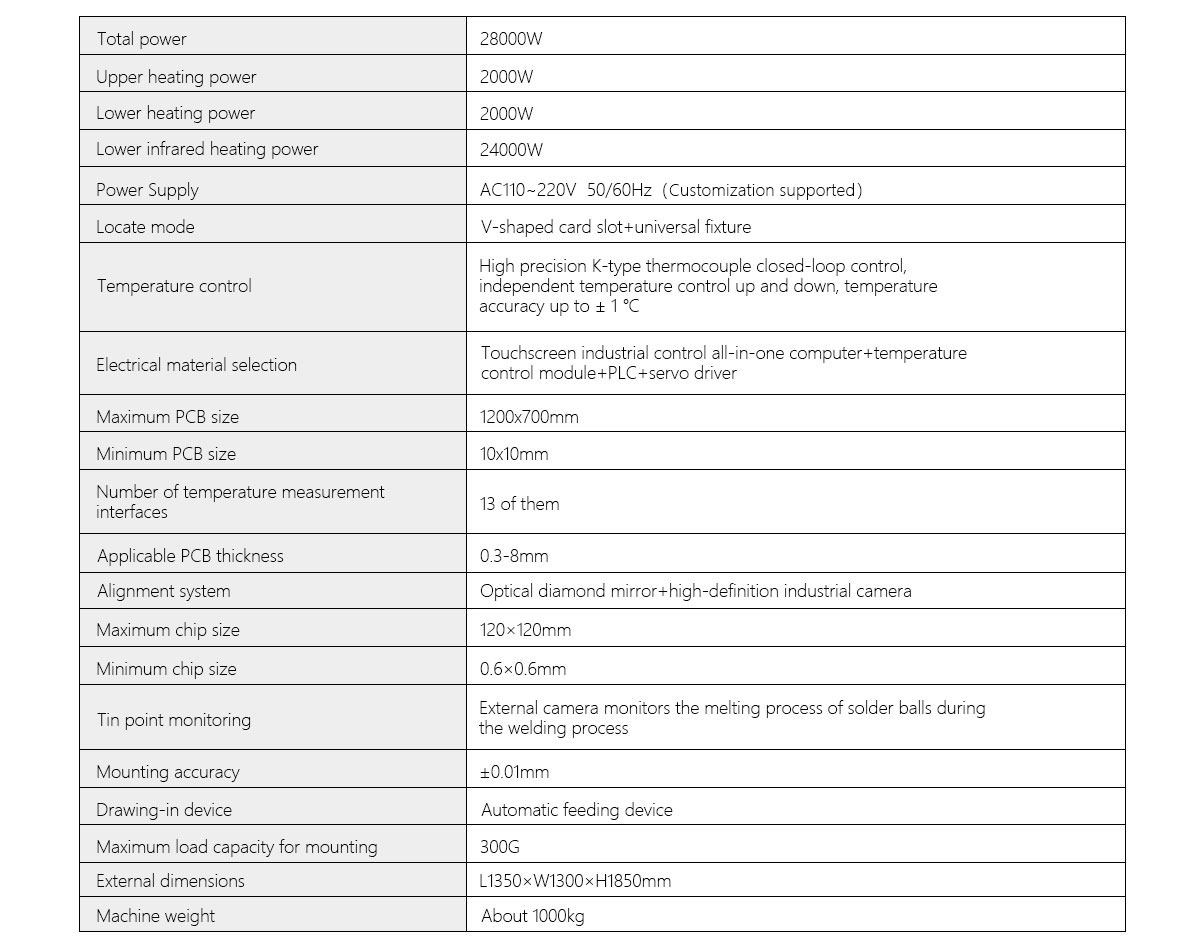

1. Self tuning temperature curve: Industrial POL and servo motion control system accurately control temperature, display real-time temperature curve, can display set curve and measured curve, and can analyze temperature measurement curve; And the temperature curve is automatically saved, making it easy to retrieve historical parameters and trace quality abnormalities. It has over temperature protection and alarm functions, and the software can be encrypted and foolproof.

2. Automatic feeding device: A vacuum suction tube is installed inside the heating head for chip adsorption, equipped with an automatic feeding device to achieve automatic feeding and feeding. It has a memory function and can complete chip disassembly and suction with one click, with simple operation.

3. Precision motion platform: Industrial control integrated computer and PLC control; Embedded industrial computer, high-precision K-type thermocouple closed-loop control, independent temperature measurement up and down, temperature accuracy up to 1 degree Celsius;

4. High definition optical alignment system: It adopts a high-definition imported CCD (8 million pixels) optical alignment system, automatic focusing, software operation function, 22x optical zoom, and automatically moves the optical lens alignment through POL control servo system. It adopts a 21.5 display screen and operation interface, and the alignment function does not interfere with the operating system, making it easy to operate.

5. High performance, multi loop heating system: 13 temperature measurement interfaces are installed externally, and high-precision K-type thermocouples are used internally, with an accuracy of up to 19C. At the same time, oxygen heating protection POBA can be connected to avoid oxidation and yellowing, and flow and negative pressure can be accurately adjusted.

6. Lower heating system: Bottom infrared preheating platform, using German imported Elstein dark infrared heating plate, fast heating, uniform preheating, and pre heatingThe thermal area reaches 650x520mm.

Equipment parameters:

Why choose BGA rework station?