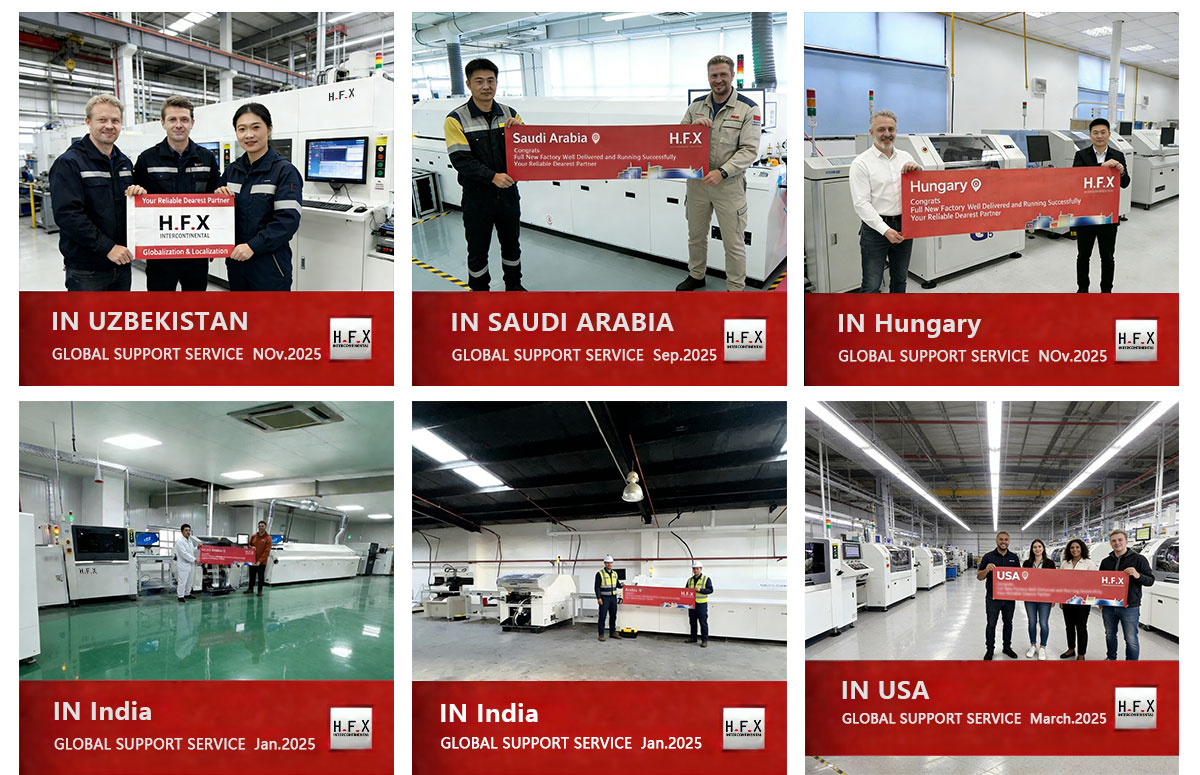

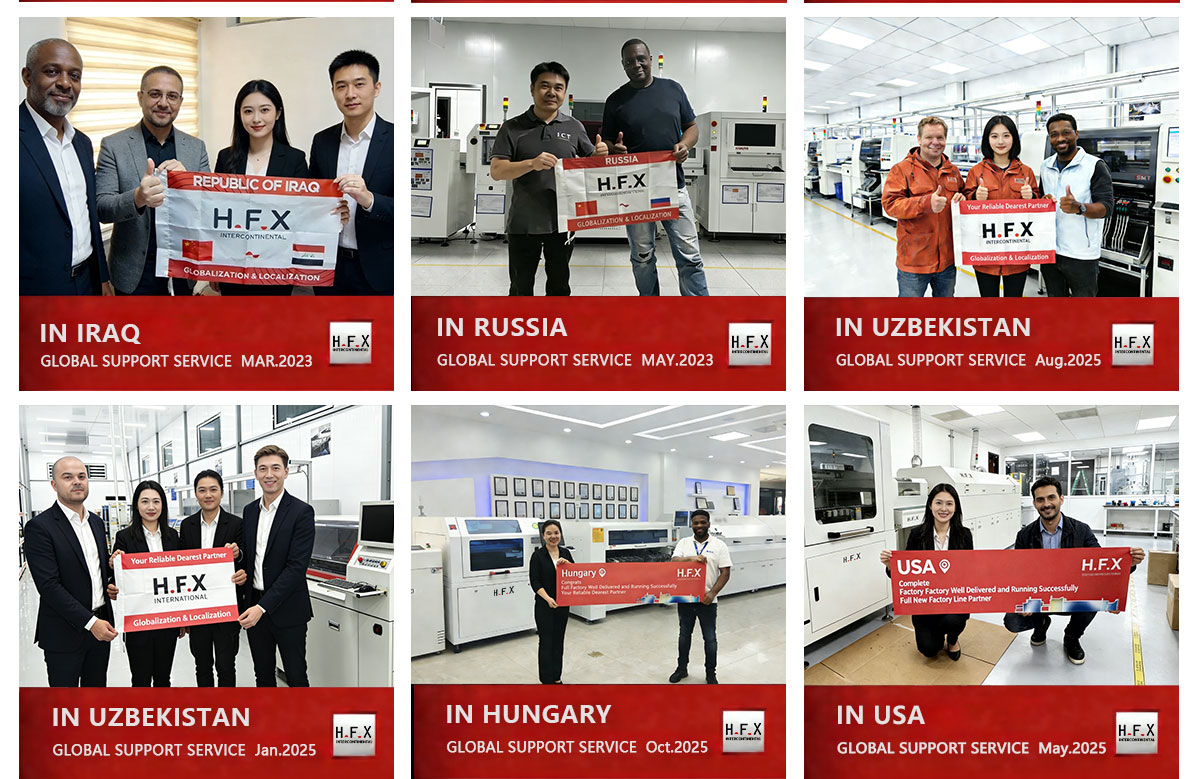

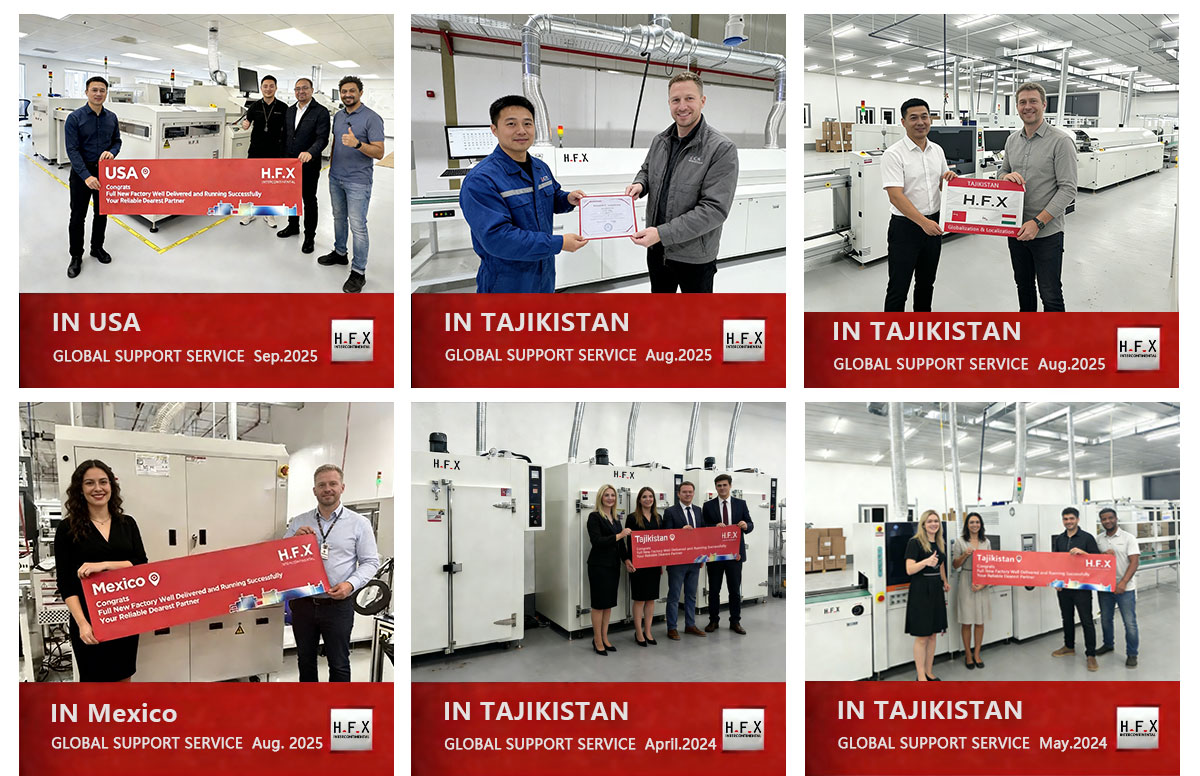

SMT production line solution

H.F.X provides turnkey SMD production line solutions tailored specifically for LED panel production. With over 12 years of experience in production line assembly, we offer professional planning and JUKI SMT production line integration. Our product line is equipped with automatic loaders, stencil printers, JUKI picker, multi-zone reflow, AOI inspection, and intelligent unloaders.

Semi-automatic or fully automatic configurations require minimal operator intervention. We provide LED panels, televisions, mobile phones, and other products to customers worldwide. A rapid 2-day installation includes layout optimization. An in-depth 5 to 15-day training covers operation and maintenance. Comprehensive support from design to launch ensures smooth factory setup. The JUKI SMT production line guarantees precision for complex LED boards.

Feature

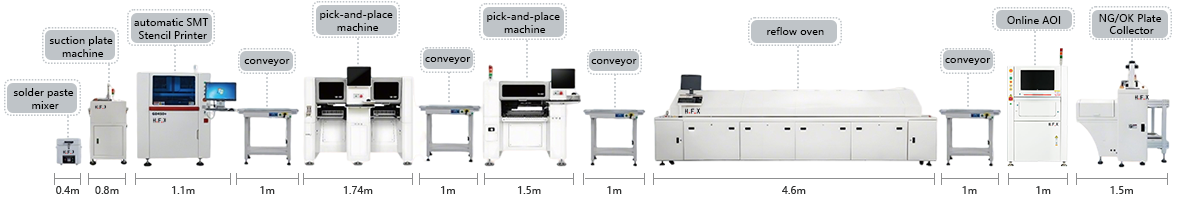

1. Seamless production line integration

Our SMD production line connects each workstation, ensuring uninterrupted flow in LED panel assembly. An automatic loader feeds clean boards into the printer, achieving uniform solder paste application. A JUKI picker mounts SMD chips with laser-guided precision. The reflow oven achieves component attachment without defects through controlled zones. After soldering, an AOI immediately detects soldering issues. An NG/OK unloader automatically separates defective products. This configuration is highly suitable for LED panel ceiling light assembly lines, especially for large-scale assembly lines.

2. Advanced Mounting Solution

JUKI technology precisely produces thousands of SMD components per hour on the SMD production line. It can quickly mount tiny parts onto PCBs. Its high speed is suitable for large-scale production. The machine coordinates with the conveyor to achieve a fully automated process. The dual-door option doubles the speed, suitable for demanding circuits. It supports ceiling light panel sizes up to 1200mm. It reduces misalignment in JUKI SMT production lines. Automatic calibration maintains consistency during long-distance operation. The program switching for product line changes is very simple.

3. Multi-zone reflux control

By heating and melting the solder paste pre-applied on the soldering pad, the electrical interconnection between the electronic component pins pre-mounted on the soldering pad and the soldering pad is achieved, thereby soldering the electronic components onto the PCB board. Independent temperature adjustment for upper and lower zones prevents damage to components due to overheating and ensures soldering quality. Rapid cooling prevents thermal stress. Nitrogen protection is selected to reduce the generation of solder balls, avoid bridging, and achieve good soldering quality. The energy-saving design meets the cost target of the SMD production line. The touchscreen interface simplifies formula management. The use of lead-free solder is more reliable.

4. Intelligent detection system

Online AOI utilizes three-dimensional imaging to scan solder joints and their positions after reflow soldering. It can detect bridges, displacements, abnormal solder quantity, or missing components within seconds. SPI achieves prevention by presetting the volume of detection paste. Data analysis tracks the trend of process adjustments. Zero defects are essential in the assembly line of LED panel ceiling lights.

5. Custom configuration selection

For startups, opt for a semi-automatic SMD production line, while for mass production, choose a fully automatic one. The modular units allow for future expansion without downtime. The factory drawings include specifications for power, air, and exhaust. We provide labor cost estimates and ROI calculations. It adheres to clean room standards.

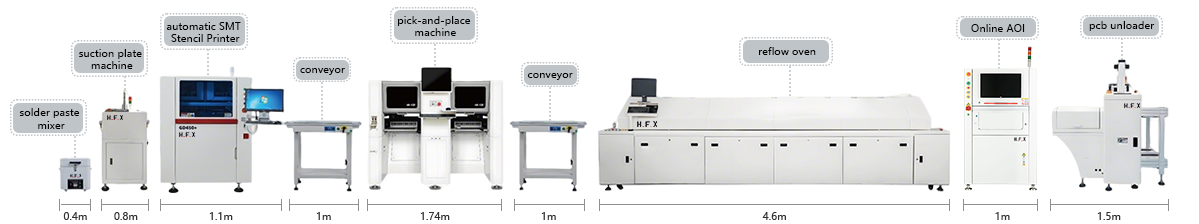

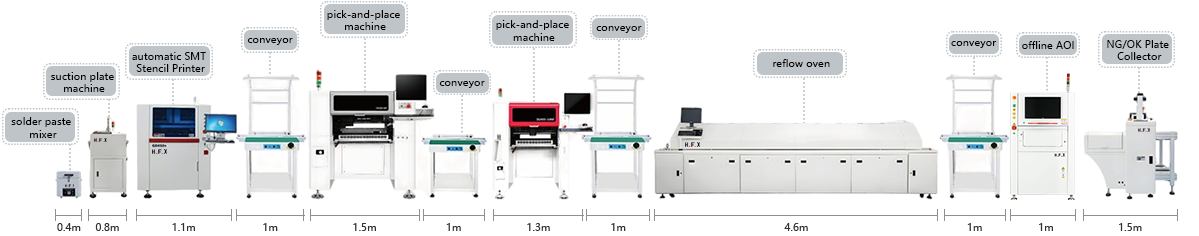

6. SMT line equipment list

The H.F.X high-quality PCBA production line is equipped with advanced equipment to achieve efficient and precise PCB assembly. The fully automated SMT series includes loaders, automatic printers for precise solder paste application, pickers for accurate component placement, reflow ovens for reliable soldering, and AOI systems for thorough defect detection. This high-quality PCBA production line ensures smooth operation, high reliability, and low-cost SMT assembly, meeting the diverse needs of the industry.

| Product Name | Purpose in SMT Line |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| AOI Machine | Inspects solder joints and placement defects. |

| SPI Machine | Checks solder paste height and quality. |

| Traceability Equipment | Records and tracks production data: Laser Marking Machine/Label Mounter/Inkjet Printer |

| SMT Cleaning Machine | Used for cleaning PCBs, stencils, fixtures, nozzles, etc. |

| PCB Routing Machine | Cut the PCBA into the final product |

Specification

| Category | Projects | Details |

Factory Layout Requirements | Factory Air Circuit Layout | Use factory air source or separate oil-free compressed air machine. Pressure should be greater than 7kg/cm². |

| Factory Electrical Layout | Single-phase AC220 (220±10%, 50/60Hz) Three-phase AC 380V (380±10%, 50/60Hz) | |

| Factory Exhaust Layout | The minimum flow rate of the exhaust duct is 500 cubic feet per minute (14.15m³/min) | |

| Factory Lighting Layout | The ideal illumination in the factory is 800~1200LUX, at least not less than 300LUX. | |

| Factory Temperature Layout | The ambient temperature of the production workshop is 23±3°C, generally 17~28°C, and the relative humidity is 45%~70%RH. | |

| Material Preparation | BOM List | List all parts and quantities needed for PCBA Production Line assembly. |

| CAD File | Digital design file to plan PCB layout and machine setup. | |

| Gerber File | Standard file for PCB manufacturing and printing stencil. | |

| Solder Paste | Material applied on pads before placing components in printer. | |

| SMD Component Materials | Surface mount parts like chips and resistors for placement. | |

| Industrial Alcohol | Used to clean boards and stencils during setup process. | |

| Splice Belt | Tape to connect feeder reels without stopping the line. | |

| Stencil | Metal sheet with holes to print solder paste accurately. |

Certifications and Standards

CE certification confirms electrical safety. RoHS compliance avoids restricted substances. ISO9001 governs systematic production. Multiple patents cover line innovations. These validate SMD Production Line reliability worldwide. Rigorous pre-shipment testing included.