Application scenarios

Ultrasonic flaw detector is a portable industrial non-destructive testing instrument that can quickly, conveniently, without damage, and accurately detect, locate, evaluate, and diagnose various internal defects (cracks, porosity, pores, inclusions, etc.) of workpieces. It can be used in both laboratories and engineering sites.

It is widely used in boiler, pressure vessel, aerospace, aviation, power, petroleum, chemical industry, offshore oil, pipeline, military industry, shipbuilding, automobile, machinery manufacturing, metallurgy, metal processing industry, steel structure, railway transportation, nuclear power, universities and other industries.

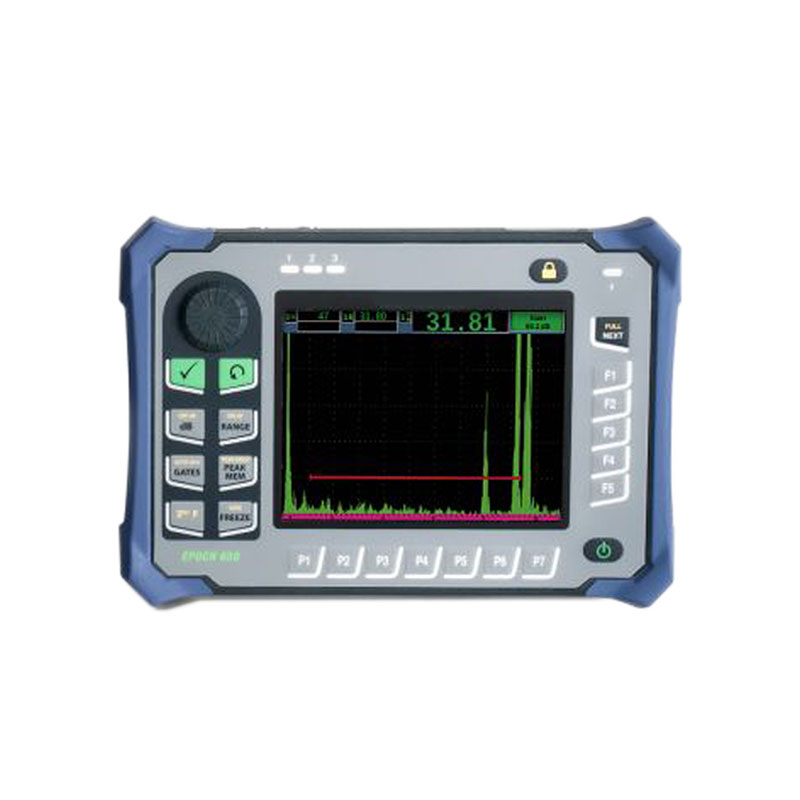

Compact and of superior quality

The spacious full VGA transparent display combined with a digital high dynamic range receiver can display stable and eye-catching A-scan images in most lighting conditions. The design of the instrument complies with the requirements of ISO-22232 standard and provides complete standard and optional flaw detection functions. Multiple onboard report production tools and a comprehensive data archiving system enable you to easily collect and report high-quality inspection data. This instrument is sturdy and durable, designed to meet ergonomic requirements, and can be used in various testing environments. The flexible PerfectSquare pulse generator and its numerous digital filters are helpful in completing most detection applications.

The digital ultrasonic flaw detector not only has the detection performance of leading conventional flaw detectors in the industry, but also has the efficient characteristics of intuitive operation and compact portable instruments. The comprehensive use of efficient menus and shortcut key access functions in the flaw detector provides you with an easy-to-use and high-quality defect detection platform.

The model design is suitable for most testing environments

Suitable for most testing environments, from laboratory bench testing to harsh and dangerous outdoor testing. The shuttle knob of the instrument meets the IP66 rating standard, and its browsing key area meets the IP67 rating standard. In addition, the instrument has passed strict testing in relevant environmental and reliability standards. Therefore, in most testing environments, users will have full confidence in the operational performance and durability of the instrument.

Key Features

1. Design in accordance with the requirements of ISO-22232 standard

2. PerfectSquare adjustable square wave pulse generator

3. Full screen A-scan mode

4. Digital high dynamic range receiver

5. 30 digital filters used to enhance signal-to-noise ratio

6.2 kHz pulse repetition frequency (PRF) for fast scanning

7. Shuttle knob or browsing key area, used to adjust configuration

8. A spacious, full VGA display screen that can be read under sunlight

9. Can work for more than 15 hours using batteries

10. Standard dynamic DAC/TCG and airborne DGS/AVG

11. Multiple onboard report formats

12. microSD memory card for data transfer

13. Optional corrosion module software with encoded B-scan

14. USB (OTG) port, used for communication with PC

15. Alarm and VGA output

16. Optional analog output

Technical Specifications

nstrument Inputs/Outputs | USB Ports | USB On-The-Go (OTG) |

| RS-232 Port | Yes | |

| Video Output | VGA output standard | |

| Analog Output | 1 analog output (optional), Selectable 1 V/10 V Full Scale, 4mA max | |

| Alarm Output | 3 alarm outputs, 5 V TTL, 10 mA | |

| Trigger I/O | Trigger input, 5V TTL;Trigger output, 5V TTL, 10 mA max | |

| Encoder Inputs | 1-axis encoder line (quadrature - Corrosion Module mode only) | |

Environmental Ratings | Explosive Atmosphere | Safe operation as defined by Class I, Division 2, Group D, as defined in the National Fire Protection Association Code (NFPA 70), Article 500, and tested using MIL-STD-810F, Method 511.4, Procedure I. |

| Shock Tested | MIL-STD-810F, Method 516.5 Procedure I, 6 cycles each axis, 15g, 11 ms half sine. | |

| Vibration Tested | MIL-STD-810F, Method 514.5, Procedure I, Annex C, Figure 6, general exposure: 1 hour each axis | |

| Operating Temperature | –10 °C to 50 °C (14 °F to 122 °F) | |

| Battery Storage Temperature | 0 °C to 50 °C (32 °F to 122 °F) | |

| General | Overall dimensions (W x H x D) | 236 mm x 167 mm x 70 mm (9.3 in. x 6.57 in. x 2.76 in.) |

| Weight | 1.6 kg (3.5 lb), including lithium-ion battery | |

| Keypad | English, International, Japanese, Chinese | |

| Languages | English, Spanish, French, German, Japanese, Chinese, Portuguese, Russian | |

| Transducer connections | BNC or Number 1 LEMO | |

| Data storage | 100,000 IDs onboard, removable 2 GB MicroSD card (standard) | |

| Battery type | Single lithium-ion rechargeable standard | |

| Battery life | 15 h to 16 h (lithium-ion) | |

| Power requirements | AC Mains: 100 VAC to 120 VAC, 200 VAC to 240 VAC, 50 HZ to 60 Hz | |

| Display type | Full VGA (640 x 480 pixels) transflective color LCD, 60 Hz update rate | |

Display dimensions (W x H, Diag.) | 117 mm x 89 mm, 146 mm (4.62 in. x 3.49 in., 5.76 in.) | |

| Pulser | Pulser | Tunable Square Wave |

| PRF | 10 Hz to 2000 Hz in 10 Hz increments | |

| Energy settings | 100 V, 200 V, 300 V or 400 V | |

| Pulse width | Adjustable from 25 ns to 5,000 ns (0.1 MHz) with PerfectSquare™ technology | |

| Damping | 50, 100, 200, 400 Ω | |

| Receiver | Gain | 0 to 110 dB |

| Maximum input signal | 20 V p-p | |

| Receiver input impedance | 400 Ω ± 5% | |

| Receiver bandwidth | 0.2 MHz to 26.5 MHz at -3 dB | |

| Digital filter settings | Thirty digital filter sets standard | |

Seven ISO 22232-1:2020 compliant filters (0.2-10 MHz, 2.0-21.5 MHz, 8.0-26.5 MHz, 0.5-4 MHz, 0.2-1.2 MHz, 1.5-8.5 MHz, 5-15 MHz) | ||

| Rectification | Full-wave, Positive Half-wave, Negative Half-wave, RF | |

| System linearity | Horizontal: ± 0.5% FSW | |

| Resolution | 0.25% FSH, amplifier accuracy ± 1dB | |

| Reject | 0 to 80% FSH with Visual Warning | |

| Amplitude measurement | 0 to 110% full screen height with 0.25% resolution | |

| Measurement rate | Equivalent to PRF in all modes | |

| Calibration | Automated calibration | Velocity, Zero Offset |

| Straight Beam (First Backwall or Echo-to-Echo) | ||

| Angle Beam (Soundpath or Depth) | ||

| Test modes | Pulse Echo, Dual, or Through Transmission | |

| Units | Millimeters, inches, or microseconds | |

| Range | 3.36 mm to 13,388 mm (0.132 in. to 527.10 in.) @ 5,900 m/s (0.2320 in./μ) | |

| Velocity | 635 m/s to 15240 m/s (0.0250 in./µs to 0.6000 in./µs) | |

| Zero offset | 0 µs to 750 µs | |

| Display delay | -59 mm to 13,401 mm (-2.320 in. to 526.97 in.) @ longitudinal velocity in steel | |

| Refracted angle | 0° to 90° in 0.1° increments | |

| Gates | Measurement gates | 2 fully independent gates for amplitude and TOF measurements |

| Gate start | Variable over entire displayed range | |

| Gate width | Variable from Gate Start to end of displayed range | |

| Gate height | Variable from 2 to 95% full screen height | |

| Alarms | Positive and Negative Threshold, Minimum Depth (Gate 1 and Gate 2) | |

| Measurements | Measurement display locations | 5 locations available (manual or auto selection) |

| Gate (1, 2) | Thickness, Soundpath, Projection, Depth, Amplitude, Time-Of-Flight, Min./Max. Depth, Min./Max. Amplitude | |

| Echo-to-Echo | Standard Gate 2-Gate 1, Optional IF Gate Tracking | |

| Other measurements | Overshoot (dB) value for DGS/AVG, ERS (equivalent reflector size) for DGS/AVG, AWS D1.1/D1.5 A, B, C and D values, Reject Value, Echo to RefdB values | |

| DAC/TCG | Standard | |

| DAC points | Up to 50 points, 110 dB dynamic range | |

| Special DAC modes | Custom DAC (up to 6 curves), 20-80% View | |

| Curved surface correction | Standard OD or Bar correction for Angle Beam measurements | |

| Corrosion (optional) | Zero-cross measurement algorithm, V-Path correction, Single or Echo-to-Echo, Encoded B-scan |