Product features:

1. Alignment accuracy:± 10.0 micron/micron @ 6 sigma; , Cp≥ 2.0.

2. Printing accuracy:± 15.0 micron/micrometer @ 6 sigma; , Cp≥ 2.0.

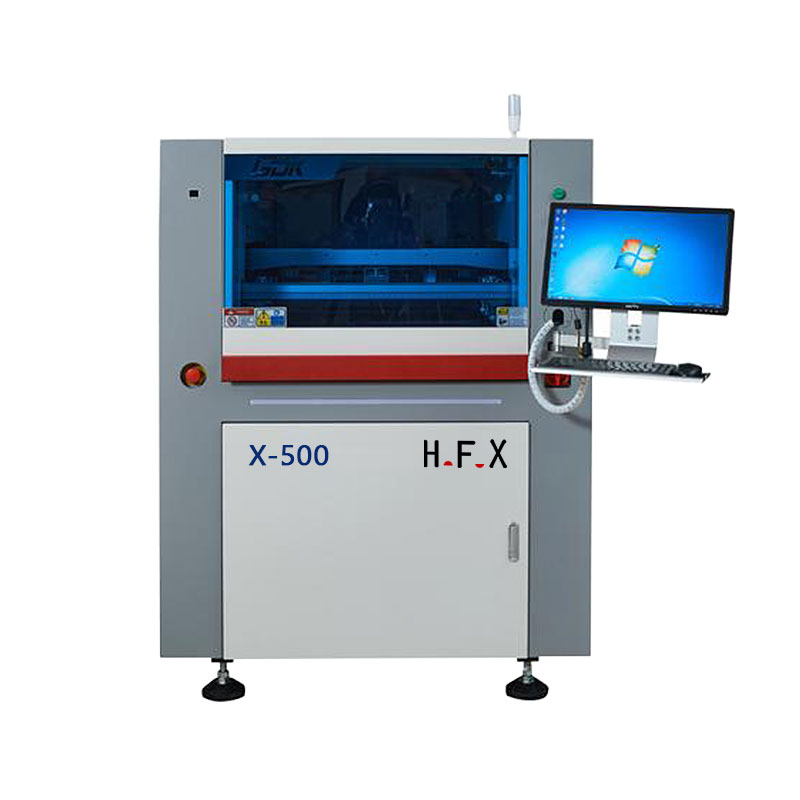

3. The fully automatic solder paste printing machine is a product designed for high-end SMT applications, with better molding and soldering capabilities for precision boards of 01005 or below. It can be placed back-to-back or used independently by a single machine. Printing surface 510mm x 510mm.

Product parameters:

| PCB Parameters | |

| Maximum board size (XxY) | 510mm x510mm |

| Minimum board size (XxY) | 50mmx50mm |

| PCB Thickness | 0.4mm~6mm |

| Warpage | MAX. PCB Diagonal 1% |

| Maximum board weight | 3Kg |

| Gap at the edge of the board | Configuration to 3mm |

| Maximum bottom gap | 20mm |

| Transmission speed | 1500mm/Second(Max) |

| Direction of transmission track | 900±40mm |

| Transmission mode | Left-Right, Right-Left, Left-Left, Right-Right(Program Settings) |

| PCB clamping method | One segment track |

| Plate support method | Programmable elastic lateral pressure+adaptive plate thickness+edge locking substrate clamping (options: 1. Bottom multi-point local vacuum: 2. Bottom integral suction chamber vacuum) |

| Printing Parameters | |

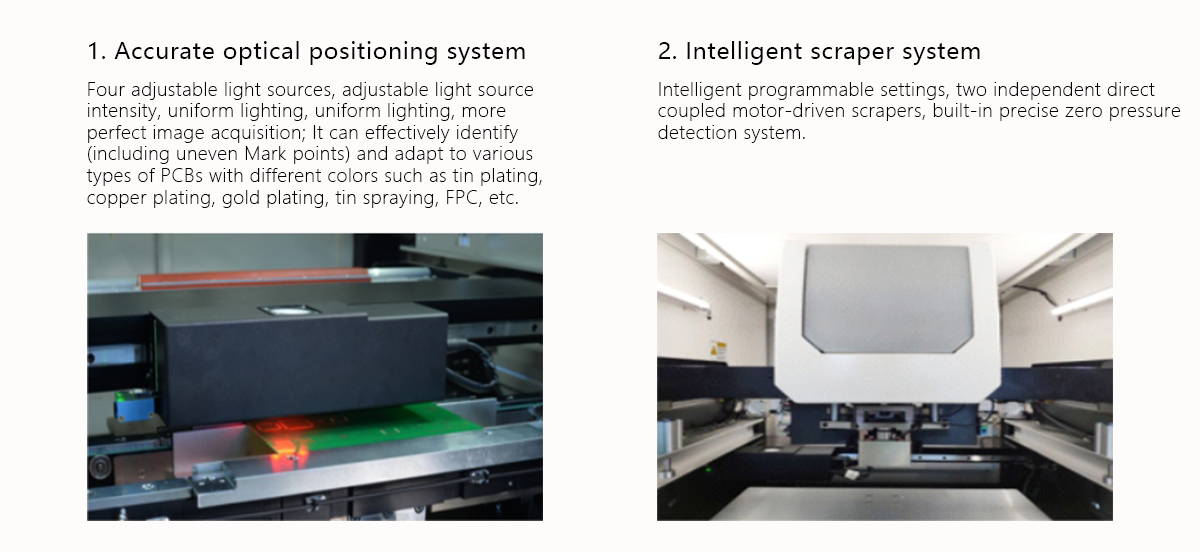

| Print Head | Suspended intelligent printing head (two independent direct coupled motors) |

| Module frame size | 470mm*370mm-737mm*737mm |

| Maximum printing area (XxY) | 510mm x510mm |

| Scraper method | Steel scraper/adhesive scraper (angle 45 °/55 °/60 ° selected according to printing process matching) |

| Squeegee length | 300mm (optional 200mm-500mm length) |

| Scraper height | 65 ±1mm |

| Thickness of scraper blade | 0.25mm Diamond like carbon coating |

| Print Mode | Single or double scraper printing |

| Demoulding length | 0.02 mm-12 mm |

| Printing speed | 0-200 mm/s |

| Printing pressure | 0.5kg-10Kg |

| Printing schedule | ± 275mm (from the center) |

| Cleaning parameters | |

| Cleaning method | 1. Drip shower cleaning system; 2. Dry, wet, and vacuum modes |

| Cleaning and wiping board length | 380mm (optional 300mm, 450mm, 500mm) |

| Images parameter | |

| Film and Television Perspective | 8mm x 6mm |

| Platform adjustment scope | X:±5.0mm, Y:±7.0mm.θ:±2.0° |

| Reference point type | Standard shape reference points (see SMEMA standard), solder pads/openings |

| Camera system | Individual camera, separate upward/downward imaging visual system |

| Performance parameter | |

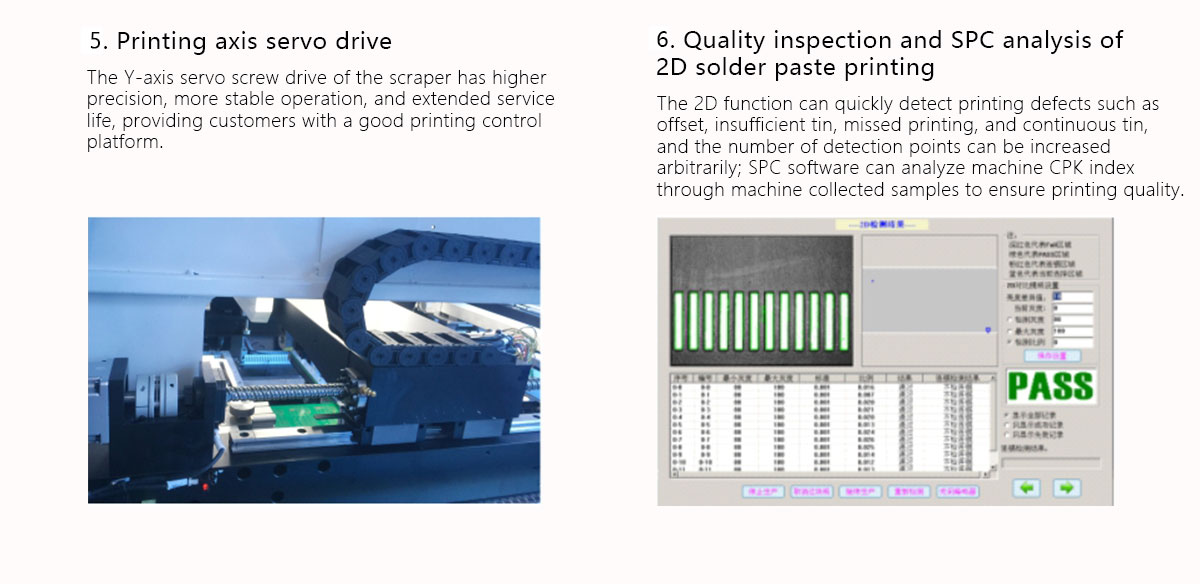

| Repetitive accuracy of image calibration | ±10.0μm@6σ,Cpk≥2.0 |

| Printing accuracy | ±15.0μm@6σ.Cpk≥2.0 |

| Cycle time | <7.5s |

| Change line time | <5mins |

| Equipment parameters | |

| Power requirements | AC110~220V 50/60HZ(Customization supported) |

| Compressed air requirements | 4~6Kg/cm2 |

| Gas consumption | About 5L/min |

| Operating system | Windows XP(Option Win7&WIN10) |

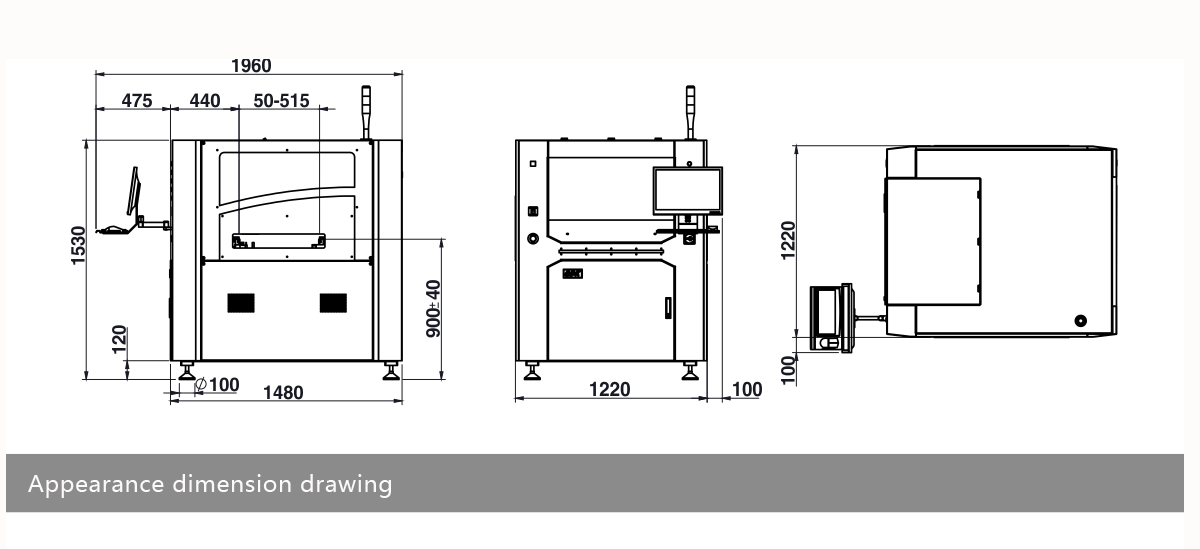

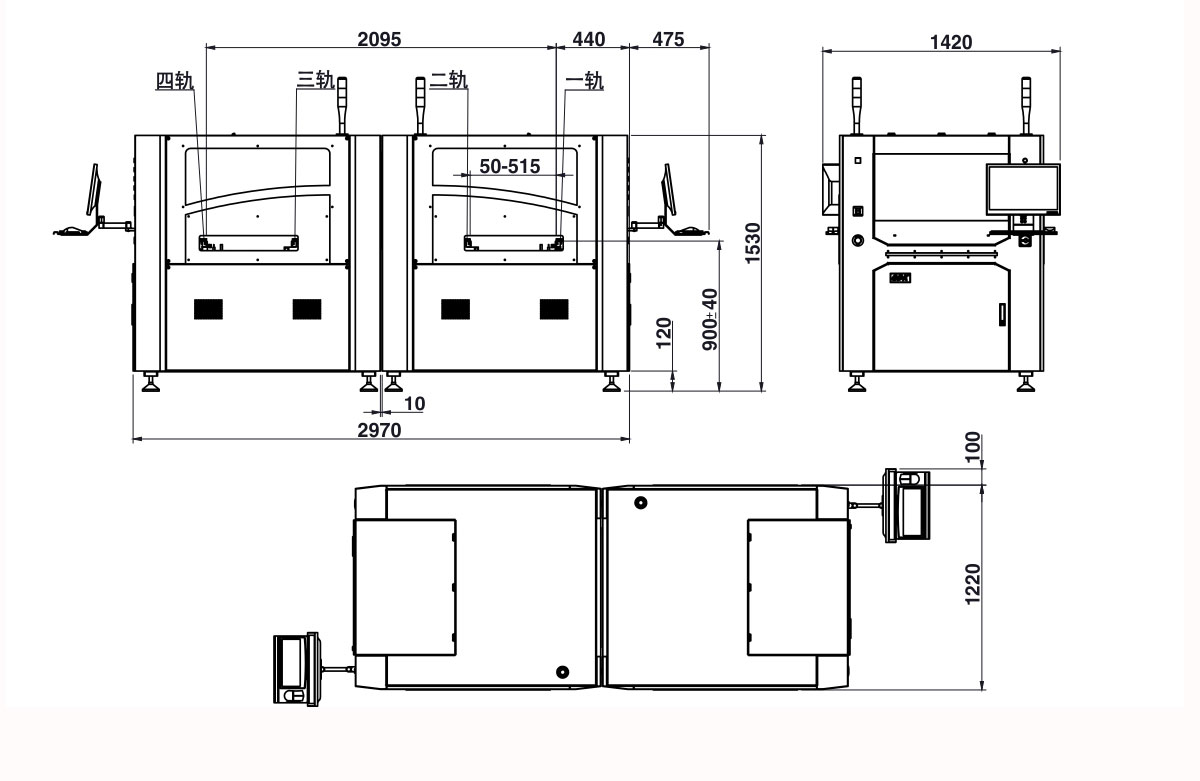

| Outline dimension | 1220mm (L) x1480mm (W) x1530mm (H) (excluding tri color lights, monitor, and keyboard) |

| Machine weight | About 1230Kg |

| User Permissions | Different users have different permissions (fingerprint recognition access/password input) |

| Ambient temperature | 23±3℃ |

| Relative humidity | 45-70%RH4 |

> Customization can be made according to customer needs.