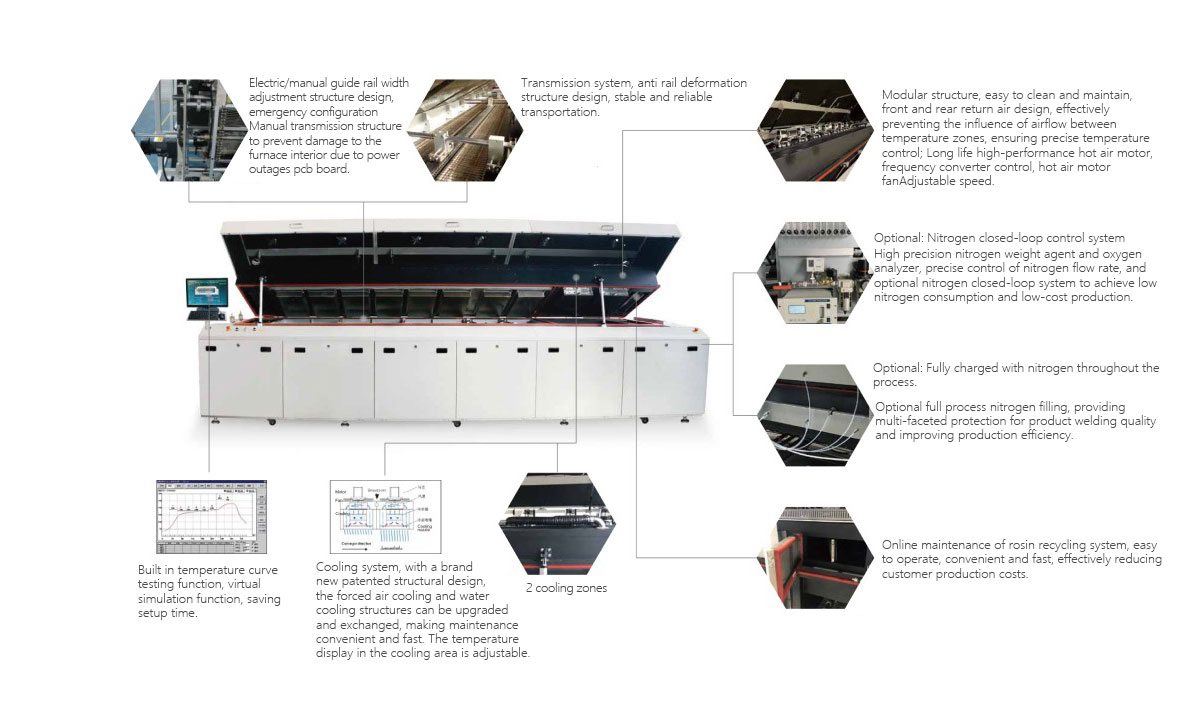

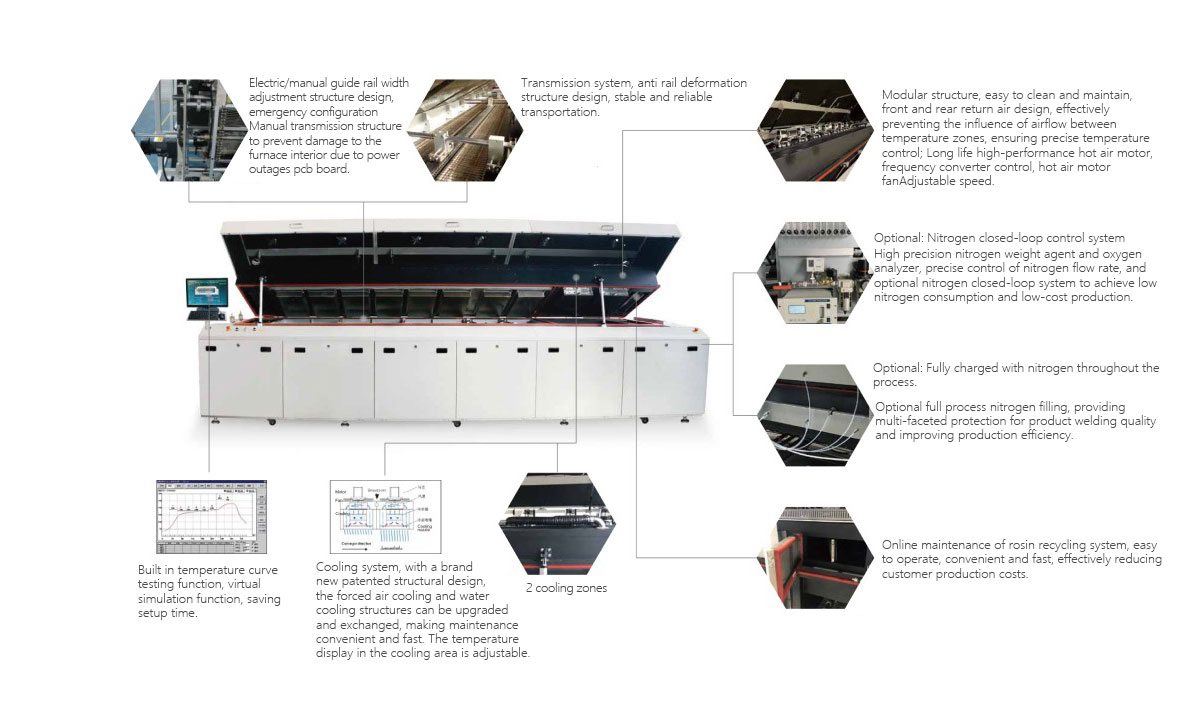

Reflow soldering SER series product features:

High thermal energy: With a professional theoretical foundation in thermal energy supply, the matching of appropriate heating power and volume ensures a large supply of thermal energy. Sufficient thermal energy to achieve optimal thermal efficiency, So as to achieve maximum production capacity in a shorter heating zone.

Low energy consumption: theoretical design and practical testing, verified by customers, Obtaining the best repeatability result CPK value and allowing numerous customers to see the lowest energy consumption at the factory site.

Thermal equilibrium: theoretical and practical verification, with the same speed and temperature setting as peers, to ensure the minimum heat absorption difference between large and small components and achieve optimal equilibrium.

Large size: With the same external dimensions of the body, it can handle larger PCB boards. The dual track can pass through the board at the same time by 300mm, and the dual track can pass through a single board by up to 550mm, which can meet the needs of many customers.

Product parameters:

| SER series rel low oven main speci lica

lions |

| Model No | HFR-5000 | HFR-5010 | HFR-5020 | HFR-5030 | HFR-5050 | HFR-5060 | HFR-5070 | HFR-5080 | HFR-5090 | HFR-5980 |

| Heating System |

| Heating Zone | 8 Heating Zones,16 Heating moudules | 10 Heating Zones,20 Heating moudules | 12 Heating Zones,24 Heating moudules | 6 Heating Zones,12 Heating moudules |

| Heating Length | 2950mm | 3670mm | 4350mm | 2230mm |

| Cooling Type | Double cooling:enforced air

cooling/water cooling (Optional:three cooling zones) | Double cooling:forced air cooling |

| Outlet Exhaust Demand,Valume | 2-Φ145, Exhaust demand 15m³/minx

2 |

| Conveyor System |

| Product Width | min50mm-max400mm |

| Conveying Direction | L→R,R→L |

| inlet Height | 900+20mm |

| Fixed Rail Side | Front rail Fixed(Option:Rear Rail

Fixed) |

| Conveyor Type | Chain+mesh belt synchronous

transmission |

| Cmponent Height | Clearance based on the rail:above

30mm, below 20mm |

| Conveying Speed | 300mm-1500mm/min |

| Control System |

| Power Supply | AC3Φ,5W,380V,50/60HZ |

| Total Power | 57KW | 71KW | 89KW | 45KW |

| Start up Power | 30KW | 35KW | 40KW | 30KM |

| Running Power | 7.5KW | 9.5KW | 11.5KW | 6KW |

| Temperature Range | Room temp to 320℃ |

| Control Type | PC+PLC Control System |

| Rail Width Adjusting Mode | Electric+Manual |

| Temp Control accuracy | ±1℃ |

| PCB Temp Deviation | ±1℃ |

| Data Storage | Process Data and status stotage |

| Power Outage Protection | Equipped with UPS |

| Operation Interface | Windows Chinese simplified, English

online free switching |

| General |

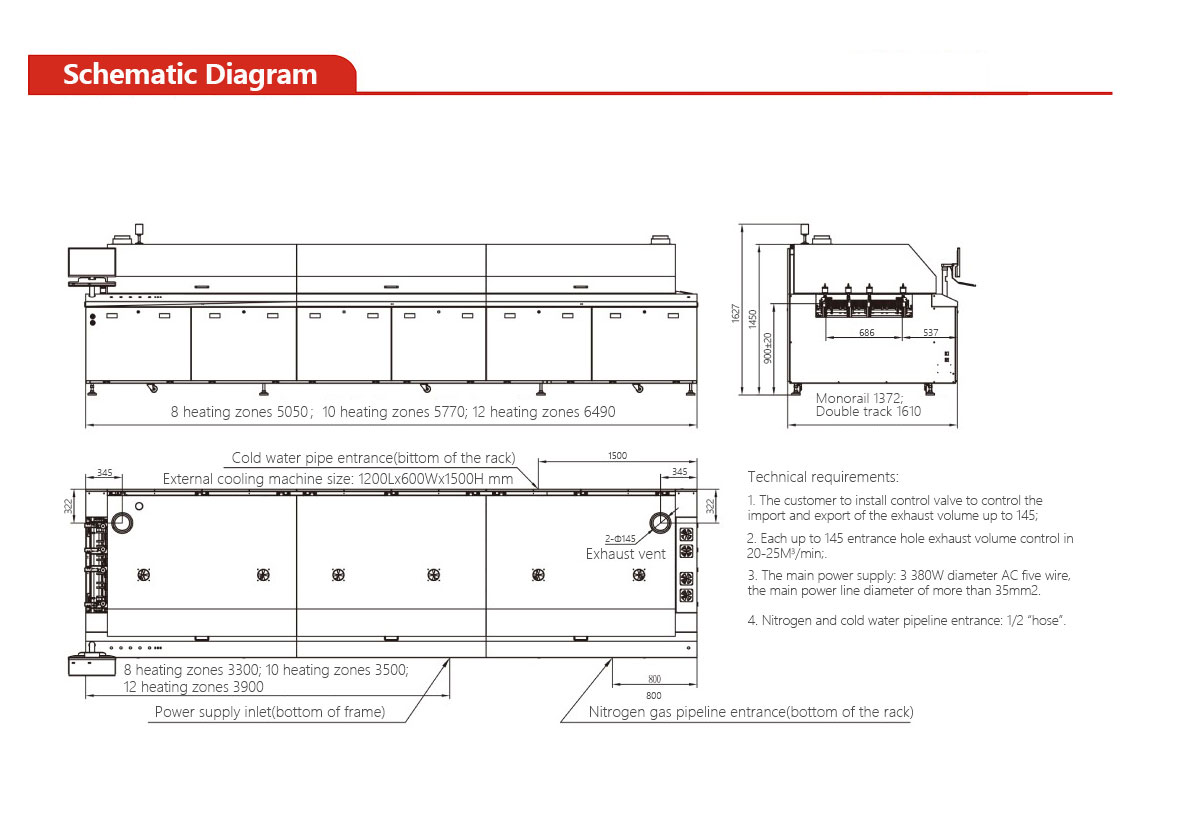

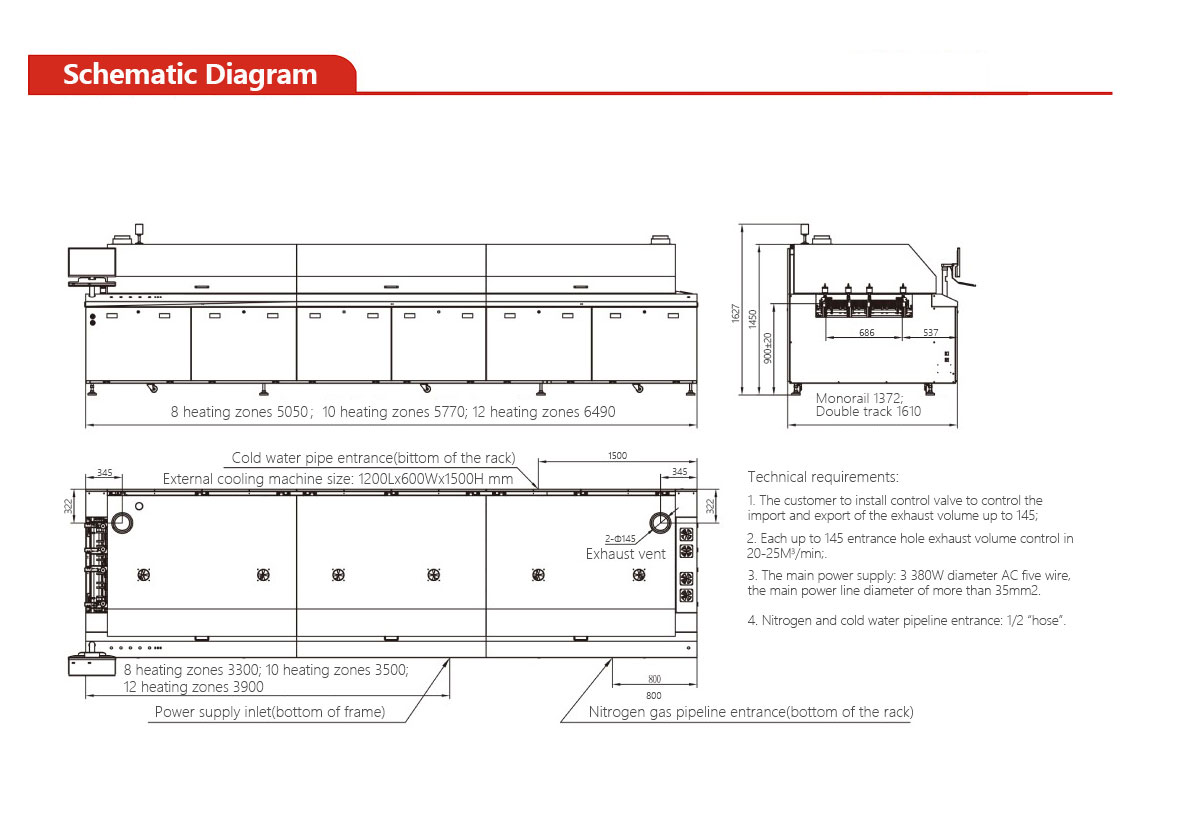

| Dimension(L×W×H) | 5055*1372*1515 | 5775*1372*1515 | 6495*1372*1515 | 4335*1372*1515 |

| Weight | 2000-2200kg | 2400-2600kg | 2800-3000kg | 1600-1800kg |

| Color | Bright wrinkled white |

> Customization can be made according to customer needs.

FAQ:

Q: What is reflow oven machine?

A: In SMT (Surface Mount Technology), a reflow oven machine is an essential component used for soldering electronic components onto printed circuit boards (PCBs). It precisely heats the solder paste, allowing it to melt and create secure connections, a fundamental step in the electronics assembly process.

Q: How does a reflow machine work?

A: A reflow machine works by gradually raising the temperature to melt the solder paste on PCBs. This controlled heating process creates reliable solder connections between components and the PCB, ensuring the functionality and durability of electronic assemblies.

Q: What are the steps in the reflow process?

A: The reflow process in SMT involves several key steps, including preheating, solder paste reflow, and cooling. Preheating prepares the assembly for soldering, solder paste reflow creates connections, and cooling solidifies the solder joints, resulting in a completed electronic assembly.

Q: What is the difference between reflow oven and wave soldering machine?

A: Reflow ovens and wave soldering machines serve different soldering needs in SMT. Reflow ovens are used for surface mount components, heating solder paste to create precise connections. Wave soldering machines, on the other hand, are used for through-hole components, using a wave of molten solder to solder the bottom side of PCBs. Each method addresses distinct assembly requirements in electronics manufacturing.

H.F.X - Our Company

About H.F.X:

H.F.X is a leading provider of factory planning solutions and industrial inspection solutions. We have 4 wholly-owned factories that provide professional consulting and services to global customers. We have over 12 years of experience in electronic integrated solutions and industrial testing solutions. We not only provide a complete set of equipment, but also offer comprehensive technical support and services, and provide customers with more reasonable professional advice. We help many clients establish factories in LED, TV, mobile phone, DVB, EMS, and other industries around the world. We will establish factories in LED, TV, mobile phone, DVB, EMS, and other industries around the world. We have also obtained strict industry certifications such as CE, FDA, AERB, etc. Our products are exported to countries such as the United States, Germany, India, Singapore, Vietnam, Thailand, Canada, the United Kingdom, France, Italy, the Netherlands, Sweden, Mexico, Brazil, etc. We are trustworthy.

Exhibition:

For SMT factory setup and industrial non-destructive testing, we can provide you with:

1. We provide you with complete SMT solutions and industrial testing solutions

2. We Provide Core Technology With Our Equipments

3. We provide the most professional technical services

4. We have rich experience in establishing SMT factories and industrial testing

5. We can solve any problems related to SMT and industrial testing

Reflow soldering equipment HFR series