Application of fully automatic repair table in the development of electronic manufacturing industry

Source:H.F.XRelease time:2025-07-06 17:07:33

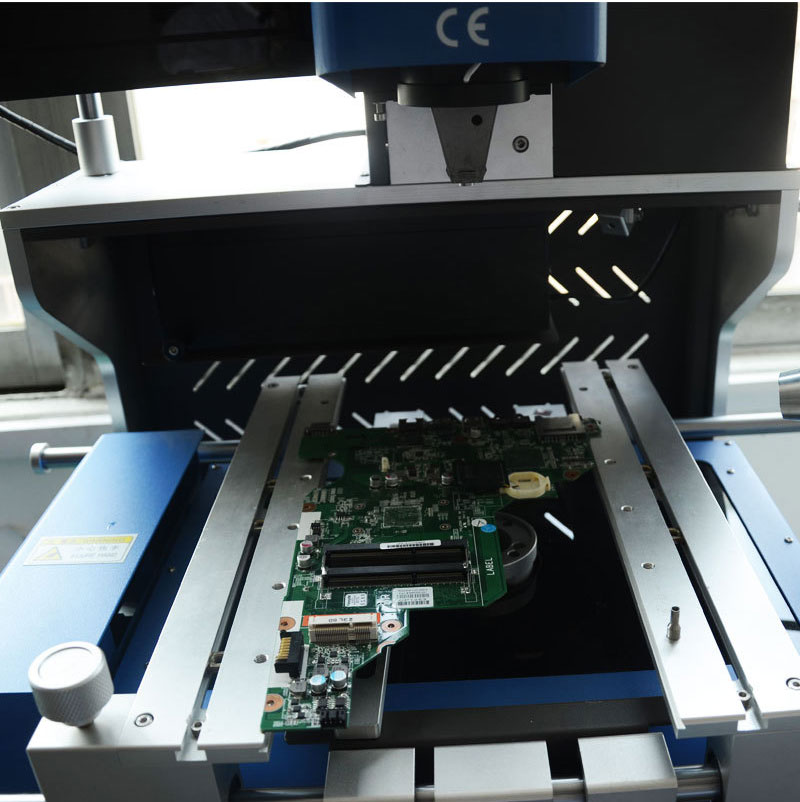

In the increasingly competitive global electronics manufacturing industry, efficiency and quality are the key to success or failure. With the increasing complexity of electronic products, the demand for electronic manufacturing equipment is also growing day by day. At this point, the fully automatic repair table of (H.F.X) has become an indispensable artifact. It is like the "Swiss Army Knife" in the electronics industry, multifunctional and incredibly precise, helping companies solve various tricky repair problems. So, how does the fully automatic repair platform help the development of the electronic manufacturing industry? Let's reveal them one by one.

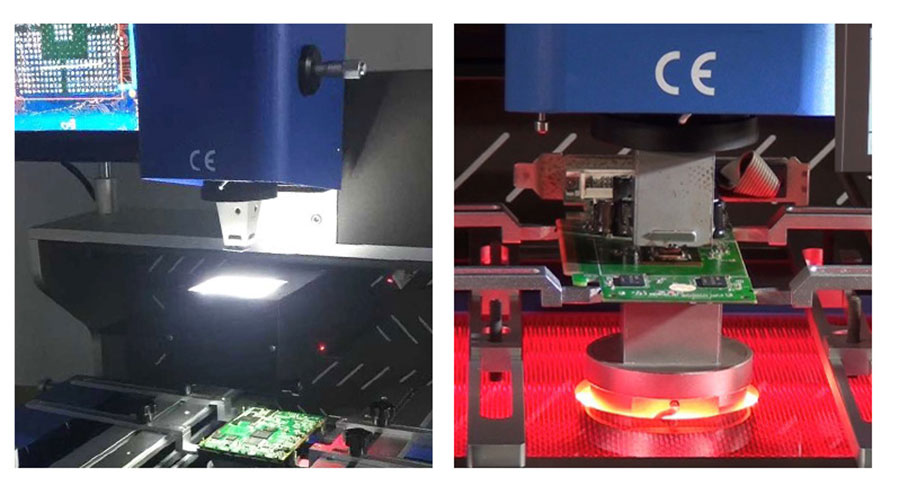

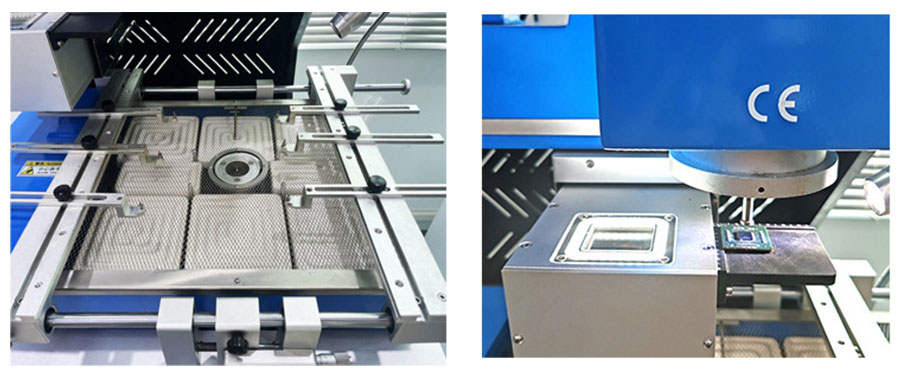

1. High precision, one "weld" to the end

The ancients said, 'To do a good job, one must first sharpen their tools.'. In complex electronic component soldering, manual operation is not only time-consuming and laborious, but also prone to welding errors. However, the fully automatic repair table of (H.F.X) can accurately locate and ensure the accuracy of welding points through a high-precision multi axis motion control system. If you have ever missed soldering a component due to shaking hands, then you can definitely feel the pain involved. The fully automatic repair table makes welding precise and complete, becoming a powerful assistant for improving production efficiency in the electronic manufacturing industry.

2. Automation reduces human involvement

In electronic manufacturing enterprises, labor costs account for a large proportion. The emergence of fully automatic repair stations has automated the repair process, greatly reducing reliance on manual labor. With simple setup and operation, the equipment can automatically complete tasks such as welding and repair. This means that companies can invest more human resources into more creative and strategic work, rather than monotonous repair operations, thereby improving overall productivity. Of course, we cannot completely 'fire' manual skilled workers, but at least let their talents be better utilized.

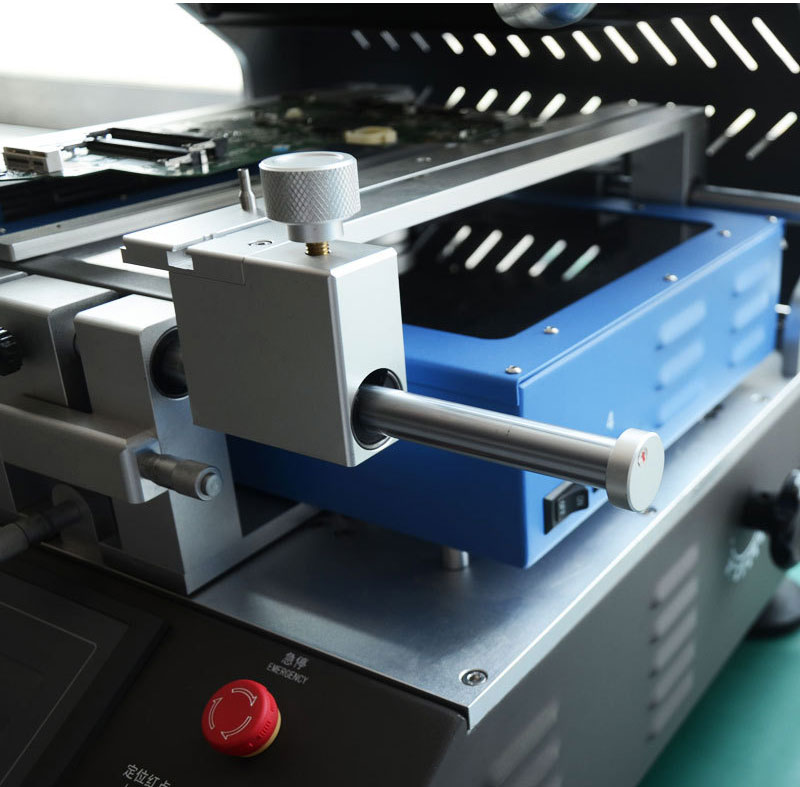

3. Flexible and adaptable to different needs

The types of products and production demands in the electronic manufacturing industry are constantly changing, and traditional repair equipment often struggles to respond flexibly. But the fully automatic repair table of (H.F.X) can be adjusted according to different needs, whether it is large-scale production or small-scale, multi variety production, the fully automatic repair table can easily cope with it. It is like an excellent "Transformers" that can freely switch and adapt to different work environments. This flexibility not only improves equipment utilization, but also enables enterprises to respond more quickly to changes in market demand.

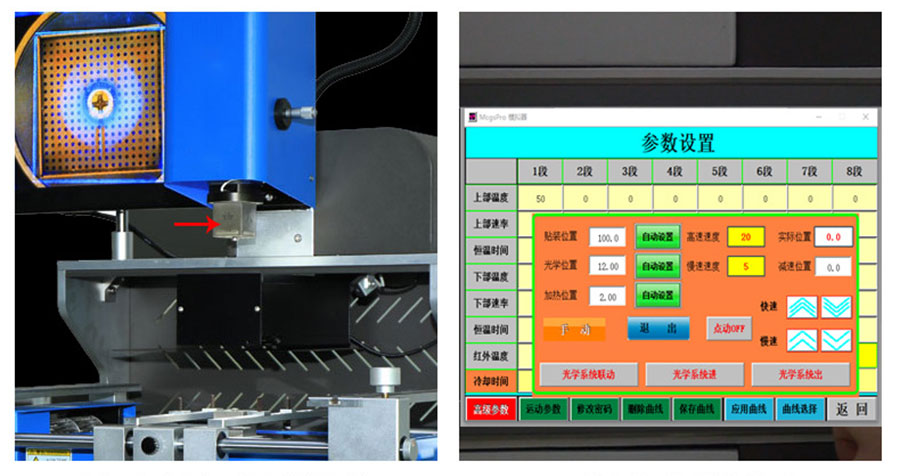

4. Efficient and stable, reducing repair rate

In the electronic manufacturing process, product repair rate is an important indicator for measuring production efficiency and product quality. The fully automatic repair station of (H.F.X) significantly reduces the repair rate through its efficient and stable performance. In the traditional manual welding process, the welding quality is difficult to guarantee, and problems such as virtual welding and leakage welding are prone to occur. The fully automatic repair table ensures that every welding point reaches its optimal state through precise temperature control and constant welding rate. Reducing the repair rate not only improves product quality, but also reduces production costs.

5. Easy to operate, short training period

The continuous development of technology has made equipment operation increasingly complex, but (H.F.X)'s fully automatic repair platform insists on the "user-friendly" route, with a simple and intuitive operating interface. At the beginning of the design, the convenience of user operation was taken into consideration, so even technicians without professional backgrounds can quickly get started. The automation level of the equipment is high, the operation steps are simple and clear, and the training period is greatly shortened. For enterprises, this undoubtedly saves a lot of training costs and time, enabling new equipment to be quickly put into use.

conclusion

Through the above analysis, we can see that in today's rapidly developing electronic manufacturing industry, (H.F.X)'s fully automatic rework station is undoubtedly a force that cannot be ignored. It not only improves production efficiency and reduces labor costs, but also enhances product quality and significantly reduces repair rates. Moreover, it is easy to operate and has a short training period, fully demonstrating the power of modern technology in the manufacturing industry.

Previous article:None

Next article:BGA Workbench Helps Electronic Manufacturing