X-RAY detection applied to fuse defects

Source:H.F.XRelease time:2025-08-29 22:36:56

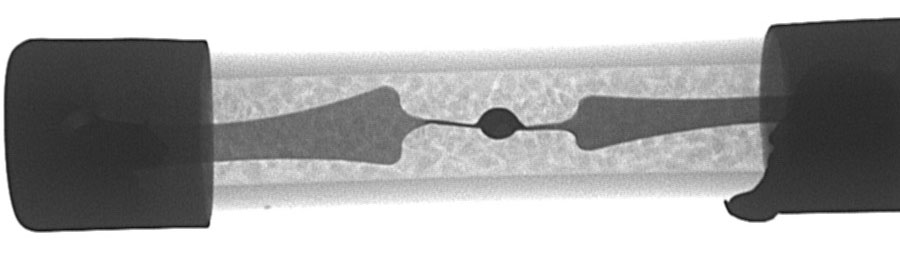

X-Ray detection fuse is a non-destructive testing technology that uses X-rays to penetrate an object and receive the transmitted X-rays on the other

side. By detecting the intensity distribution of the transmitted X-rays, the internal structure and defects of the object can be inferred. In the process

of fuse manufacturing, X-RAY testing is widely used to detect internal defects and quality control of fuses.

A fuse is an electrical protective component used to cut off current in the event of overload or short circuit in a circuit, thereby protecting the circuit

and equipment. Therefore, the quality and reliability of fuses are crucial for the normal operation of electrical systems. The application of X-RAY

detection technology can greatly improve the quality and reliability of fuses, reduce the rate of defective products, and improve production efficiency.

When conducting X-ray inspection, the fuse needs to be placed on the inspection table of the X-ray machine, and then X-rays are emitted through the

fuse by the X-ray machine. During the process of X-ray penetration through a fuse, if there are defects such as pores, inclusions, cracks, etc. inside the

fuse, the transmission intensity of X-rays will change. The X-ray machine receives transmitted X-rays and converts them into digital signals. Through

computer processing and analysis, the internal structure and defect information of the fuse can be obtained.

The advantages of X-RAY detecting fuses are their non-destructive nature, high precision, and high efficiency.

Firstly, X-RAY testing will not cause any damage to the fuse, so it will not affect the electrical performance of the fuse. Secondly, X-RAY detection can

accurately detect defects inside the fuse, including tiny pores and inclusions, thereby ensuring the quality and reliability of the fuse. Finally, X-RAY

detection can quickly complete a large number of detection tasks, improving production efficiency.

In addition to X-ray testing, there are other testing methods that can be used for quality control of fuses, such as visual inspection, mechanical

performance testing, etc. However, these methods often have some limitations, such as visual inspection can only detect surface defects, while

mechanical performance testing can only detect the mechanical properties of fuses and cannot detect internal defects. Therefore, X-RAY detection,

as a comprehensive and accurate detection method, plays an irreplaceable role in the fuse manufacturing process.

In practical applications, there are still some issues to pay attention to when detecting fuses with X-RAY. Firstly, the selection and configuration of

X-ray machines need to be adjusted based on factors such as the size, shape, and material of the fuse to ensure optimal detection results. Secondly,

attention should be paid to radiation safety during the detection process to avoid harm to operators and the surrounding environment. Finally, the

interpretation and analysis of X-RAY test results need to be carried out by professional technicians to ensure accuracy and reliability.

In short, X-RAY detection of fuses is an important non-destructive testing technology that can greatly improve the quality and reliability of fuses, reduce the rate of defective products, and improve production efficiency. In practical applications, attention should be paid to the selection and configuration of X-ray machines, radiation safety, and interpretation and analysis of detection results to ensure detection effectiveness and safety.

Previous article:X-RAY detection applied to USB connectors

Next article:X-ray detection applied to sensors

Recommend

-

X-RAY detection applied to fuse defects

With the development of modern technology, sensors have been widely used in various industries, incl

2025-06-30 -

X-RAY detection applied to fuse defects

X-ray inspection of joints is a method of internal inspection using X-ray technology, widely used in

2025-06-30 -

X-RAY detection applied to fuse defects

In the production and application process of LED light strips, quality control has always been a foc

2025-06-30 -

X-RAY detection applied to fuse defects

In modern industrial production, product quality is one of the core elements of enterprise competiti

2025-06-26 -

X-RAY detection applied to fuse defects

In modern industrial production, sensors, as an important electronic component, are widely used in v

2025-06-26