The key role of X-ray detection equipment applied to connectors in industrial quality control

Source:H.F.XRelease time:2025-08-29 23:09:19

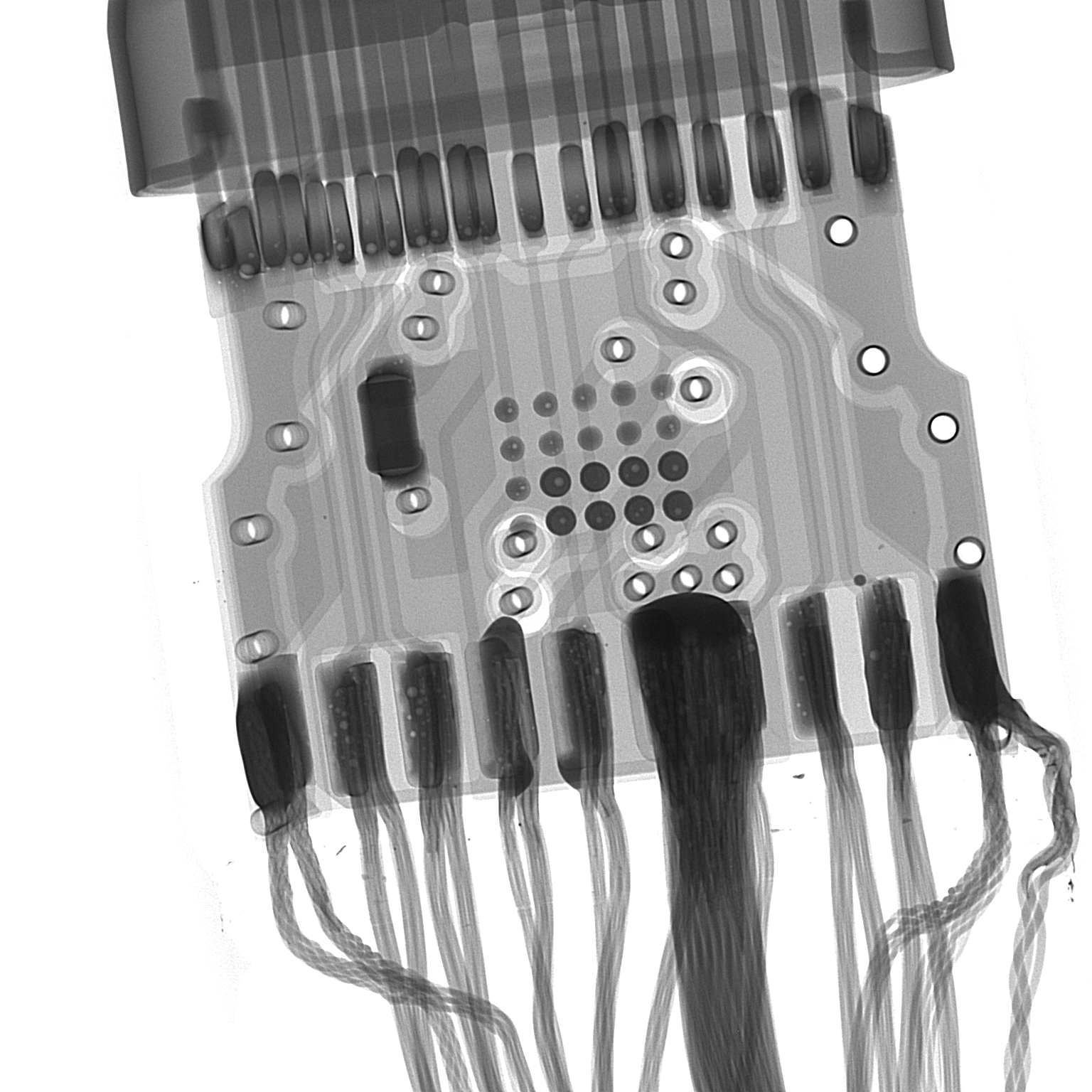

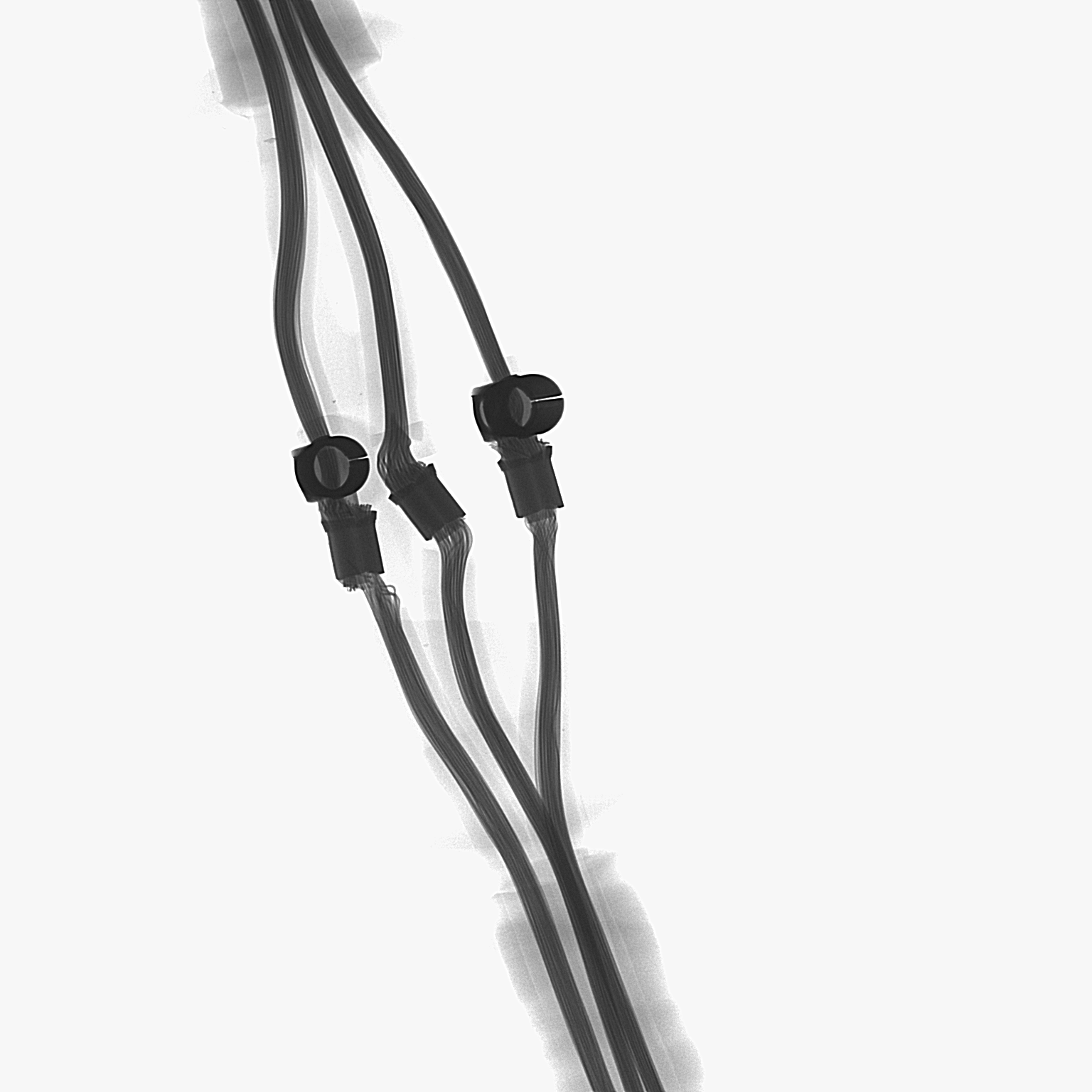

In modern industrial production, product quality is one of the core elements of enterprise competitiveness. In order to ensure the high reliability and safety of products, non-destructive testing technology is increasingly being valued. Among them, X-ray detection technology has been widely used in various industries due to its penetrability and high resolution. X-ray testing is a non-destructive testing method that utilizes the characteristic of X-rays penetrating through materials, and detects changes in the intensity of the penetrating radiation through a detector to obtain information about the internal structure of an object. It can be used to detect defects inside materials, such as cracks, pores, inclusions, etc., as well as measure parameters such as thickness and density of objects. X-ray detection technology is widely used in fields such as aerospace, automotive manufacturing, electronics industry, medical devices, etc.

The X-ray equipment for detecting connectors needs to have the following key characteristics:

*High precision positioning: Ensure that the X-ray beam accurately illuminates the measured area, avoiding detection errors.

*Stable mechanical performance: withstand various forces during equipment operation to ensure the stability of the testing process.

*Good electrical performance: achieving effective transmission of X-ray signals, reducing signal loss and interference.

*Radiation resistance: Long term operation in high-intensity X-ray environments to maintain stable performance.

Key points for selecting X-ray detection connectors

*Types and parameters of X-ray equipment: including voltage, current, focal size, etc. of X-ray tubes.

*Types and performance of detectors: including resolution, sensitivity, dynamic range, etc.

*The material and size of the object being tested determine the X-ray penetration capability and detection range.

*Factors such as temperature, humidity, and vibration in the working environment: affect the reliability and lifespan of connectors.

*Regulatory and standard requirements: Ensure that connectors comply with relevant safety and performance standards.

During the selection process, it is recommended to communicate with professional connector inspection machine suppliers and choose the most

suitable product based on specific application requirements.

Application fields of X-ray detection connectors

*Aerospace: Detecting defects in aircraft components such as engine blades, turbine disks, etc.

*Automotive manufacturing: Testing the welding quality and casting defects of automotive components.

*Electronic industry: Testing the internal structure and connection quality of integrated circuits and printed circuit boards.

*Medical devices: Testing the internal structure and material integrity of medical devices.

With the continuous advancement of technology, X-ray testing is developing towards miniaturization and integration, adapting to more compact

device designs and more flexible application scenarios. High speed data transmission: meets the requirements of high-resolution and high frame

rate X-ray imaging. Intelligence and automation: achieve automatic identification, diagnosis, and maintenance of connectors. Resistant to extreme

environments: Adapt to harsher working environments such as high temperatures, high pressures, strong radiation, etc.

In addition to business leaders who require the use of X-ray equipment, the following groups of people may also be interested in X-ray testing

connectors - non-destructive testing technicians: understanding the performance and selection of connectors can better carry out testing work.

Equipment manufacturer: Choosing appropriate connectors can improve the overall performance and reliability of the equipment. Research

institutions: Researching new connector technologies can promote the development of X-ray detection technology.

Recommend

-

The key role of X-ray detection equipment applied to connectors in industrial quality control

With the development of modern technology, sensors have been widely used in various industries, incl

2025-06-30 -

The key role of X-ray detection equipment applied to connectors in industrial quality control

X-Ray detection fuse is a non-destructive testing technology that uses X-rays to penetrate an object

2025-06-30 -

The key role of X-ray detection equipment applied to connectors in industrial quality control

X-ray inspection of joints is a method of internal inspection using X-ray technology, widely used in

2025-06-30 -

The key role of X-ray detection equipment applied to connectors in industrial quality control

In the production and application process of LED light strips, quality control has always been a foc

2025-06-30 -

The key role of X-ray detection equipment applied to connectors in industrial quality control

In modern industrial production, sensors, as an important electronic component, are widely used in v

2025-06-26