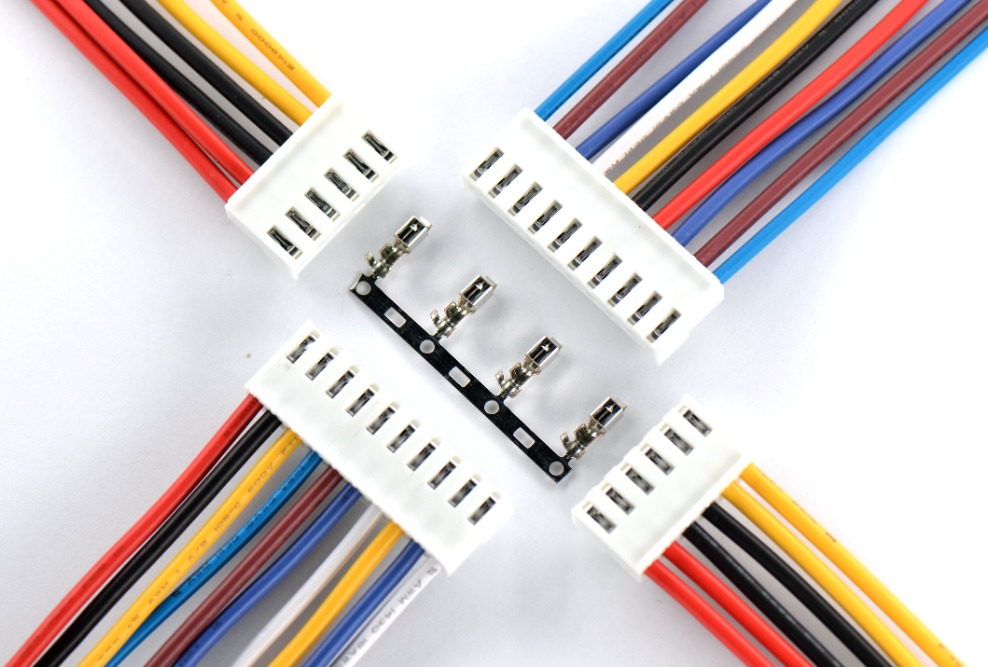

X-RAY detection applied to USB connectors

Source:H.F.XRelease time:2025-08-29 22:43:33

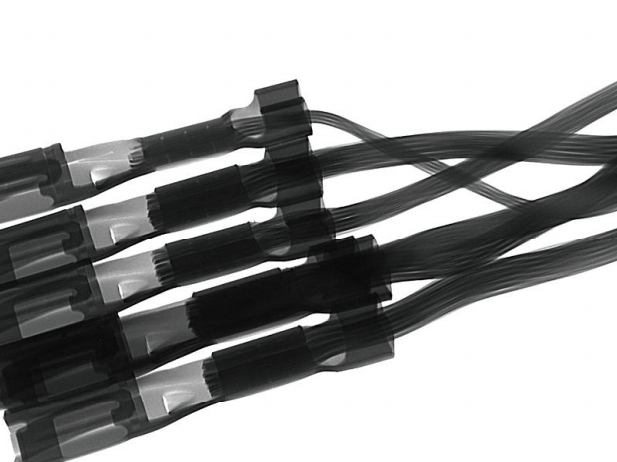

X-ray inspection of joints is a method of internal inspection using X-ray technology, widely used in various industrial fields.

X-rays have the ability to penetrate matter, and the internal structure and morphology information of matter can be obtained through the absorption and scattering of X-rays by different substances. In joint inspection, X-ray technology can help us accurately determine the quality of the joint, whether there are defects, and the type and degree of defects, thereby ensuring the safety and reliability of the joint.

When conducting X-ray inspection of joints, the first step is to select appropriate X-ray equipment and parameters. The selection of equipment should

be determined based on the size, material, and testing requirements of the joints. At the same time, it is necessary to consider parameters such as

X-ray energy, exposure time, and focal length to obtain clear X-ray images.

When conducting X-ray inspection, the following points should be noted. Firstly, it is necessary to ensure that the surface of the joint is clean and avoid

interference from impurities and oil stains on the X-ray image. Secondly, it is necessary to choose the appropriate angle and position for shooting to

obtain the best image effect. In addition, professional analysis and interpretation of X-ray images are required to accurately determine the quality and

defect situation of the joints.

X-ray inspection joints have a wide range of applications in multiple fields. In the aerospace field, joints are an important component of aircraft and

spacecraft, and their quality and safety are crucial for flight safety. Through X-ray inspection, defects such as cracks, pores, and inclusions inside the

joint can be detected in a timely manner, ensuring that the quality of the joint meets the requirements. In the field of automobile manufacturing, joints

are widely used for connecting body structures and engine components. X-ray inspection can detect the welding quality and internal defects of joints,

ensuring the safety and reliability of automobiles. In the electronic manufacturing industry, X-ray inspection can be used to detect the connection

between electronic components and circuit boards, ensuring the quality and performance of products.

In addition to the aforementioned application areas, X-ray inspection joints can also be applied to multiple other fields. For example, in the petrochemical industry, joints are used to connect pipelines and equipment, and their quality and safety are crucial for the stability and safety of the production process. Through X-ray inspection, corrosion, cracks, and leaks inside the joint can be detected in a timely manner, ensuring the smooth progress of the production process. In the field of medical devices, connectors are used to connect components such as surgical instruments, infusion tubes, and implants. X-ray inspection can ensure the quality and safety of medical device joints, safeguarding the safety and health of patients.

X-ray inspection of joints is an important non-destructive testing technique with broad application prospects. Through X-ray inspection, we can

accurately determine the quality and defect situation of the joint, ensuring its safety and reliability. In the future development, with the continuous

advancement of X-ray technology and the expansion of application fields, X-ray detection joints will play an important role in more fields, contributing

to industrial development and social progress.

Previous article:X-Ray detection applied to improve the quality control of LED light strips

Next article:X-RAY detection applied to fuse defects

Recommend

-

X-RAY detection applied to USB connectors

With the development of modern technology, sensors have been widely used in various industries, incl

2025-06-30 -

X-RAY detection applied to USB connectors

X-Ray detection fuse is a non-destructive testing technology that uses X-rays to penetrate an object

2025-06-30 -

X-RAY detection applied to USB connectors

In the production and application process of LED light strips, quality control has always been a foc

2025-06-30 -

X-RAY detection applied to USB connectors

In modern industrial production, product quality is one of the core elements of enterprise competiti

2025-06-26 -

X-RAY detection applied to USB connectors

In modern industrial production, sensors, as an important electronic component, are widely used in v

2025-06-26