X-ray non-destructive testing equipment for castings: precise identification of porosity and crack defects

Source:H.F.XRelease time:2025-08-29 23:37:54

The quality control of castings in the manufacturing industry has become a top priority in ensuring product performance. With the continuous

improvement of end users' requirements for product quality, traditional appearance inspection methods are no longer able to meet current

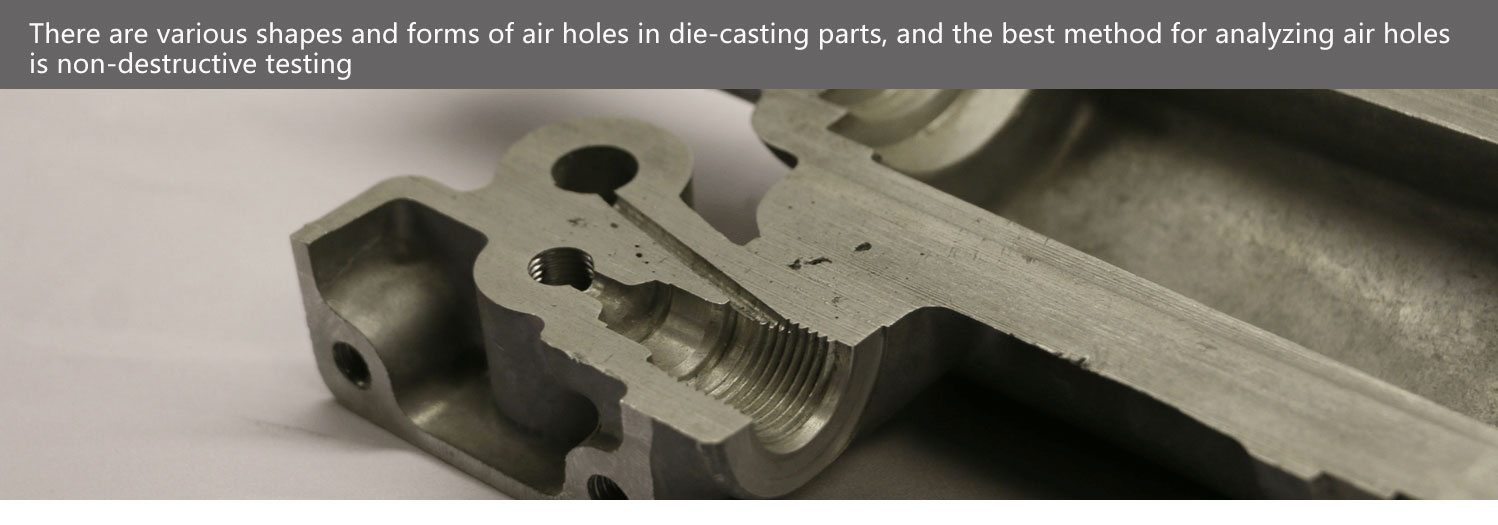

production needs. Among them, the problem of internal porosity in castings is particularly tricky, especially in the production process of aluminum

die castings. The existence of porosity may lead to a decrease in product performance and even cause quality hazards in subsequent processes.

Faced with this challenge, X-ray non-destructive testing technology has become an indispensable quality control tool for manufacturing enterprises

with its unique advantages.

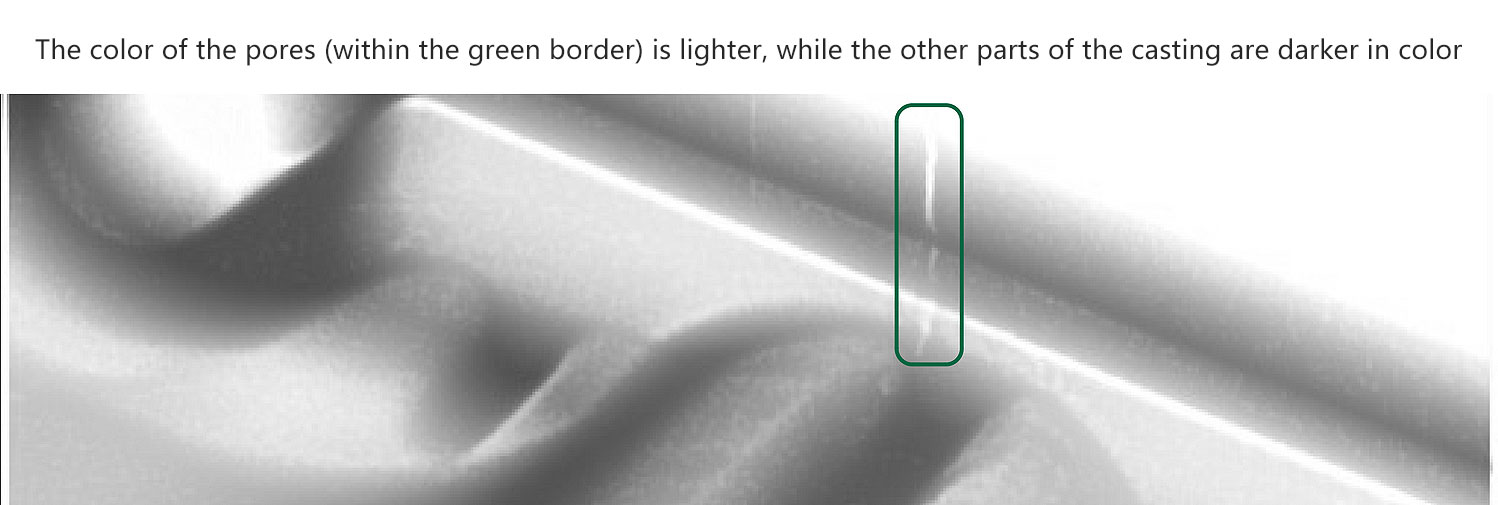

The working principle of X-ray non-destructive testing technology is to use the difference in radiation penetration ability to identify defects inside

materials. When X-rays are irradiated onto castings, dense material areas will show deeper images, while low-density areas such as pores will

present shallower images. This detection method can not only accurately locate the position of pores, but also record key information such as the

size, shape, and distribution density of pores in detail, providing reliable data support for subsequent process improvements. More importantly,

this testing method will not cause any damage to the castings after completion of the testing, and the tested products can still be put into

production use.

In practical applications, X-ray non-destructive testing technology has demonstrated multiple values. It can help enterprises establish a complete quality traceability system. By analyzing the testing data, engineers can accurately determine whether pores will affect product performance, and thus develop reasonable quality acceptance standards. During the product development phase, X-ray inspection can assist in optimizing mold design and process parameters, reducing the generation of pores from the source. For the already formed pores, enterprises can adopt targeted remedial measures such as vacuum impregnation based on the test results to maximize the recovery of non-conforming products and reduce production costs.

For production managers, timely detection and control of porosity issues are of great significance. X-ray inspection can not only identify potential

quality issues in the early stages of production and prevent unqualified products from flowing into subsequent processes, but also help enterprises

continuously optimize production processes through data accumulation. Although porosity is difficult to completely avoid during the casting process,

the application of X-ray detection technology allows companies to control it within an acceptable range, ensuring product quality and maintaining

production efficiency.

Currently, with the rapid development of intelligent manufacturing, X-ray detection technology is constantly innovating, and the detection accuracy

and efficiency have been significantly improved. For enterprises that require quality control of castings, equipping them with advanced X-ray

inspection equipment has become a necessary investment to enhance competitiveness. This technology can not only help enterprises establish a

more comprehensive quality management system, but also provide scientific basis for process improvement, ultimately achieving a dual

improvement in product quality and production efficiency.

Previous article:X-ray non-destructive testing of metal welding, efficient quality inspection

Next article:None