BGA Workbench Helps Electronic Manufacturing

Source:H.F.XRelease time:2025-07-02 22:46:34

Whether it's electronic engineers or maintenance technicians, with the development of technology, the tools and equipment we use in our work are

constantly being upgraded. And among them, BGA workbench is undoubtedly an important invention. In today's electronic manufacturing and

maintenance field, BGA workbenches are receiving increasing attention due to their unique functions and uses. So what exactly is a BGA workbench?

What is its function? Today, let's delve into this topic together.

Perhaps you have heard of BGA workbench, but are not very familiar with its specific functions. BGA, Ball Grid Array, also known as Ball Grid Array, is

an electronic packaging technology. In this technology, there are many small ball shaped solder joints at the bottom of the chip, which can effectively

increase the strength and thermal conductivity. To ensure that these balls can be accurately soldered onto the circuit board, we need to use a BGA

workbench. The BGA workbench is not only a soldering platform, but also a complex system that combines various technologies such as heating,

suction, and positioning to ensure that each soldering point can achieve the best results.

As a leader in this field, H.F.X offers a variety of BGA workbenches suitable for different needs and applications. We will divide the introduction into

several parts to gain a detailed understanding of the main functions and roles of BGA workbench. We hope that through these introductions, you can

better understand and use this tool.

1、 Basic Structure and Principle of BGA Workbench

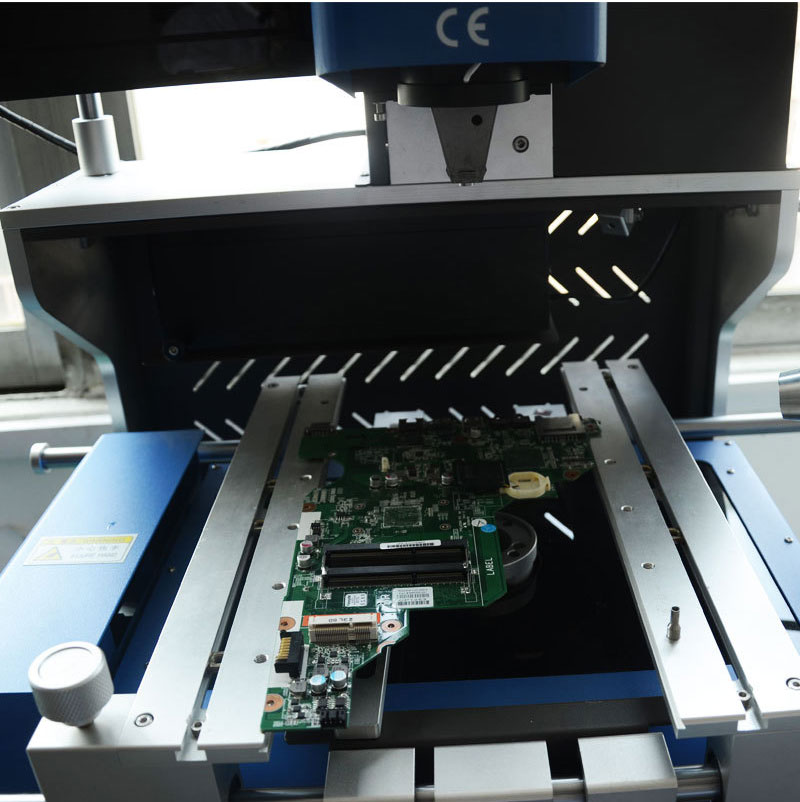

To understand the function of BGA workbench, it is necessary to first recognize its basic structure and working principle. A complete BGA workbench

typically includes the following parts:

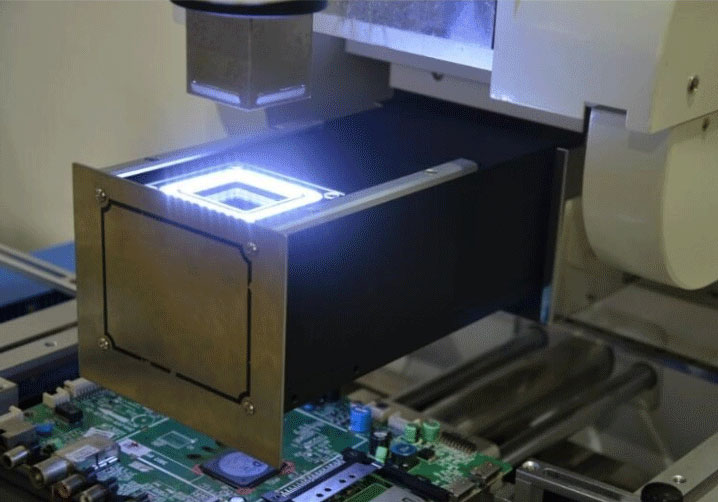

Heating system: used to heat chips and circuit boards, usually including infrared heaters and hot air guns.

Suction system: The chip is sucked in by a suction nozzle to ensure that its position does not shift.

Positioning system: A high-precision positioning system can ensure that the chip is accurately aligned with the solder joints on the circuit board.

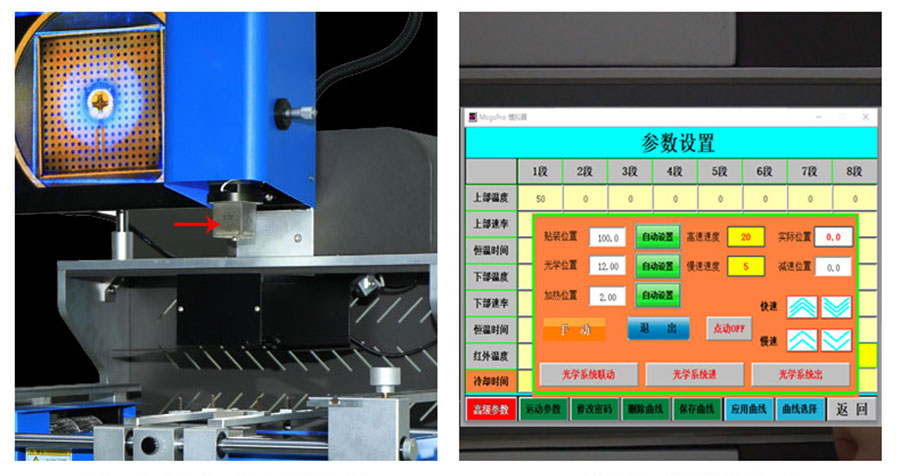

Control system: controls various parts of the entire platform, including adjusting parameters such as temperature, wind speed, and time.

Through the collaborative work of the above parts, the BGA workbench can greatly improve the accuracy and efficiency of soldering. The principle is to

first preheat the welding area to a suitable temperature with the help of a heating system, then use a suction system to stably adsorb the chip, and then

use a positioning system to fine tune it, ultimately achieving perfect welding.

2、 The main functions of BGA workbench

The BGA workbench provided by H.F.X is highly functional and suitable for various complex soldering tasks. The following are several main functions of BGA workbench:

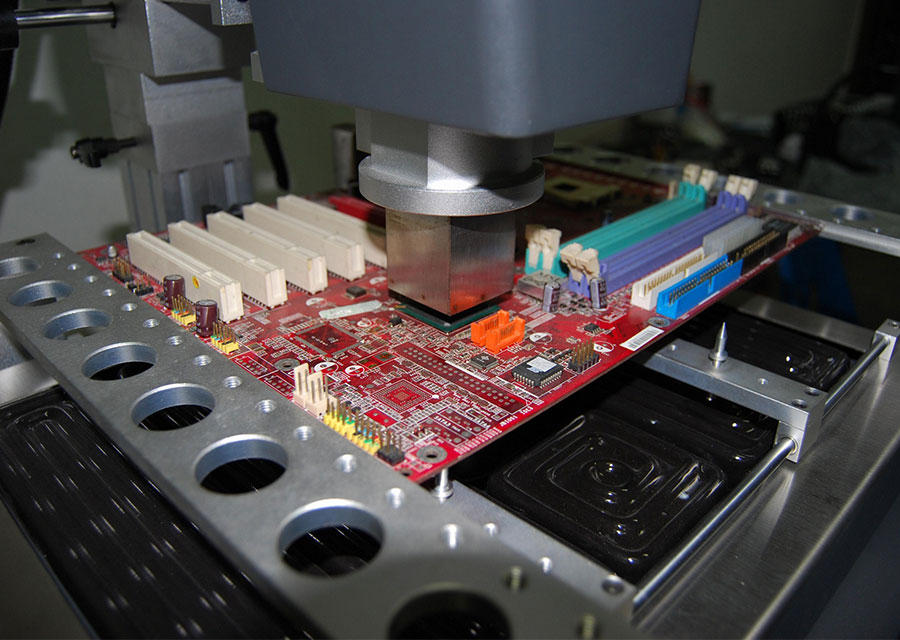

Precise soldering: The BGA workbench can achieve extremely precise soldering through a high-precision positioning system and heating system, which is particularly important for repairing and assembling small electronic devices.

Temperature control: Temperature control is the key to BGA soldering. The BGA workbench of H.F.X is equipped with advanced temperature controllers, which can achieve precise temperature control in different steps, effectively preventing overheating or insufficient.

Multifunctionality: Different models of BGA workbenches are equipped with multifunctional accessories to accommodate components of different sizes, shapes, and packaging types.

Automated operation: Automated functions can greatly reduce the workload of operators, improve work efficiency, and reduce the occurrence of human errors.

It can be said that the BGA workbench of (H.F.X) not only provides powerful soldering capabilities, but also has adjustable flexibility and multifunctionality, suitable for various electronic manufacturing and maintenance scenarios.

3、 Application of BGA Workbench in Production

BGA workbench plays an indispensable role in modern electronic production processes. Especially in the production of electronic devices with

high-density and high-performance requirements, such as smartphones, tablets, and advanced microcontrollers, the role of BGA workbench is particularly prominent.

On the production line, BGA workbench can greatly improve production efficiency and reduce scrap rate through its efficient and precise soldering function. BGA workbench supports batch processing and can complete soldering tasks for multiple chips at once. Zhicheng Jingzhan has designed an efficient BGA workbench from the perspective of meeting user needs, ensuring reliability and stability during the production process.

With BGA workstations, manufacturing companies can reduce labor costs while improving product quality and production speed. The application in production is not only a choice of tools, but also a strategic choice to stand out in a fiercely competitive market.

4、 Application of BGA Workbench in Maintenance Field

Not only in production, BGA workbench also plays an important role in the field of electronic device maintenance. Nowadays, electronic devices are becoming increasingly complex, and more and more chips are being packaged in BGA, which makes traditional maintenance methods inadequate. The BGA workbench solves this problem and becomes a "divine weapon" for technicians.

Repairing a device that uses BGA packaged chips often requires disassembly, re soldering, and other operations. It is difficult to achieve this without professional tools. The BGA workbench of Zhicheng Jingzhan makes maintenance simpler and more efficient through its high-precision positioning and temperature control system. Whether dealing with small solder joints or dealing with complex circuit board structures, it can be handled with ease.

Previous article:Application of fully automatic repair table in the development of electronic manufacturing industry

Next article:None