The specific application of X-ray marking machine in electronic manufacturing

Source:H.F.XRelease time:2025-08-29 23:22:47

With the continuous advancement of electronic manufacturing technology, the size of electronic components is becoming increasingly miniaturized and complex. This poses higher requirements for the management and testing of components in the production process, especially in inventory management and material counting. The traditional manual material counting method is not only time-consuming and labor-intensive, but also prone to human errors. To address this challenge, modern electronic manufacturing has gradually introduced the efficient and accurate technology of X-ray marking machines. The X-ray material counting machine utilizes X-ray technology to accurately and quickly complete the counting and testing of components, greatly improving production efficiency and quality control. So, what are the specific applications of X-ray marking machines in electronic manufacturing? What about its prospects? This article will explore from the following aspects.

1. Efficient and accurate material counting

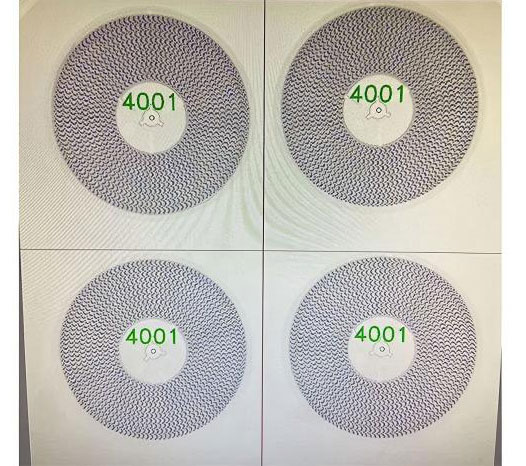

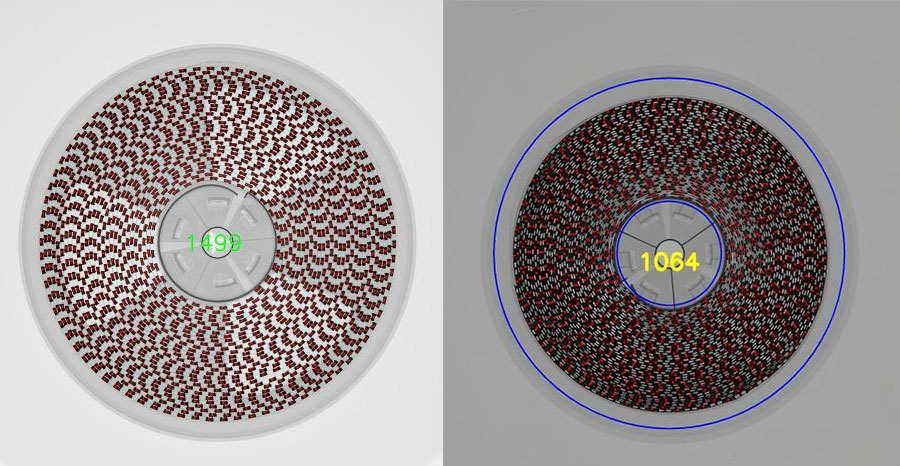

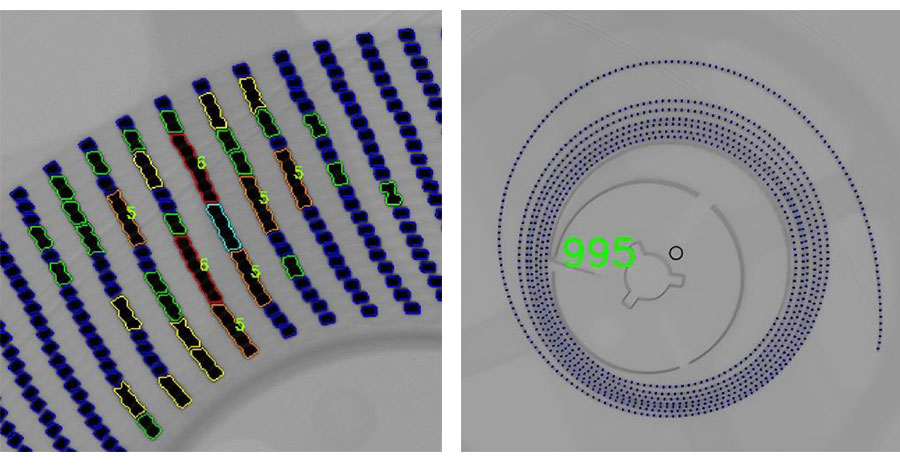

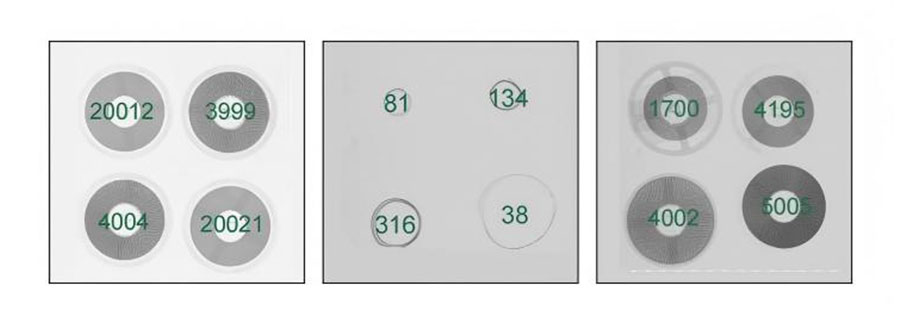

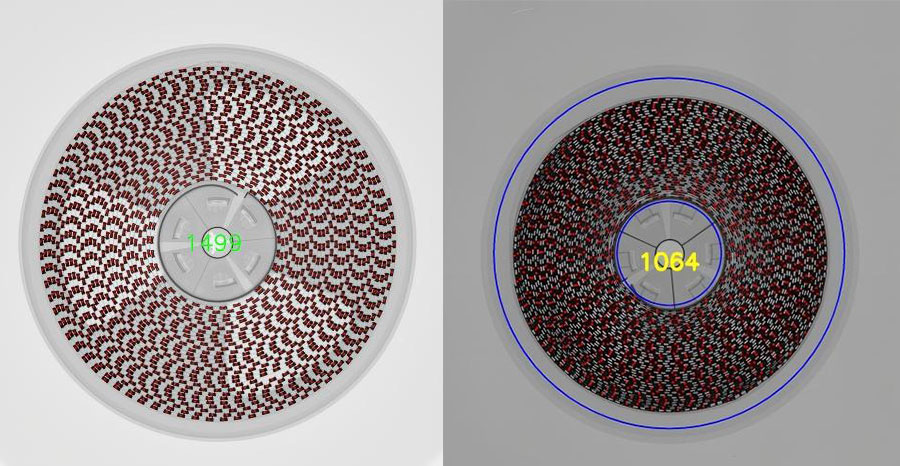

Traditional material counting methods often rely on human labor or simple optical recognition equipment, which often proves inadequate when faced with high-density and high complexity circuit boards. The X-ray marking machine has broken through this bottleneck. By utilizing the characteristic of X-ray penetrating materials, the X-ray marking machine can accurately count the components on the circuit board without damaging the original components. Compared to manual operation, the X-ray marking machine has extremely high efficiency and can process thousands of circuit boards per hour. It can also automatically identify and calculate small and complex components, avoiding errors that may occur during manual operation and ensuring high accuracy of counting results. For large-scale electronic manufacturing enterprises, this improves production speed, saves labor costs, and ensures the accuracy of inventory management.

2. Diversification of application fields

The X-ray marking machine is not limited to the production line of a certain electronic product, and its application fields are very wide. From mobile phones and computers to automotive electronics and medical equipment, almost all industries that require high-precision management of component inventory can benefit from it. For example, in the production of high-density memory chips or complex multi-layer circuit boards, X-ray marking machines can accurately identify and count each layer and component, ensuring that there are no missing or omitted parts during the production process. In fields with high standard requirements such as medical equipment, X-ray marking machines can provide non-destructive testing to ensure that every component accurately meets design requirements. This not only improves product quality but also enhances the reliability of the entire production line.

3. Intelligent and data-driven management

With the continuous advancement of Industry 4.0 and intelligent manufacturing, X-ray marking machines are also developing towards intelligence and dataization. Modern X-ray marking machines are not only capable of completing basic marking functions, but also equipped with intelligent algorithms and networking capabilities, which can monitor and analyze data in real-time during the production process. For example, it can predict possible future demand and inventory through historical data analysis, and make procurement and production arrangements in advance. By integrating with the ERP/MES system of the enterprise, the X-ray material counting machine can also achieve fully automated inventory management, allowing production and management to grasp inventory and production status in real time and optimize resource allocation. These intelligent features make the X-ray marking machine not only a marking tool, but also an indispensable part of the enterprise's intelligent manufacturing process.

4. Environmental Protection and Safety

Environmental protection and safety are important factors that cannot be ignored in modern manufacturing industry. The X-ray marking machine

also has significant advantages in this regard. X-ray technology itself belongs to non-contact detection and will not cause any physical damage to

components, thereby reducing the generation of electronic waste. Modern X-ray marking machines attach great importance to the safety of operators

in their design, and are equipped with various protective measures such as protective doors, automatic shutdown devices, and radiation shielding

technology to ensure the safety and reliability of the operating environment. By improving the efficiency and accuracy of material counting, the X-ray

material counting machine indirectly reduces rework and waste caused by human errors, and overall improves resource utilization, in line with the

concept of green manufacturing.

5. Future development direction

Looking ahead to the future, X-ray marking machines will develop towards greater diversity and intelligence. With the continuous advancement of artificial intelligence and big data technology, future X-ray marking machines can integrate more intelligent algorithms to further improve the accuracy and efficiency of marking. With the popularization of IoT technology, X-ray point machines are expected to achieve a higher degree of networking and automation, thus better integrating into intelligent manufacturing systems. At the same time, technological advancements in core components such as X-ray sources and detectors for X-ray marking machines will continue to improve their performance and reliability.

In summary, the X-ray marking machine, as an efficient, precise, and intelligent marking tool, has shown great potential for application in the electronic manufacturing industry. From improving the efficiency and accuracy of material counting, to a wide range of application fields, to intelligent data management and environmental protection features, X-ray material counting machines are gradually becoming an indispensable part of modern electronic manufacturing processes. With the continuous advancement of technology and the expansion of applications, X-ray marking machines will play a more important role in future electronic manufacturing. For related enterprises, investing in and introducing X-ray point feeding machines can not only improve production efficiency and quality, but also gain an advantage in fierce market competition and obtain greater development space. I hope readers can have a comprehensive understanding of the application and prospects of X-ray marking machines in electronic manufacturing during the reading process, and develop a stronger interest in this technology.

Previous article:None

Next article:The advantages of X-ray marking machine in SMT processing

Recommend

-

The specific application of X-ray marking machine in electronic manufacturing

1.X-rays can penetrate different objects and be used for X-ray imaging to detect the internal condit

2025-06-30 -

The specific application of X-ray marking machine in electronic manufacturing

1. Many electronic component manufacturers or contract manufacturers have scattered electronic compo

2025-06-30