Micro XCT: Non destructive X-ray testing equipment for internal defects such as chip solder joints and ceramic filters

Source:H.F.XRelease time:2025-06-29 22:56:45

Using industrial X-ray CT to visualize the "inner" of products, outsmart quality challenges with intelligence

In modern industrial production, product quality is the lifeline of enterprise development. Especially for key components such as chip resistor solder

joints, ceramic filters, batteries, and car shift covers, small internal defects can lead to serious quality problems and even pose safety hazards.

Traditional destructive testing methods are not only expensive, but also cause damage to products. Industrial micro focus X-ray computed

tomography (Micro XCT) technology has emerged, bringing revolutionary non-destructive 3D testing solutions to various industries.

Micro XCT: Your 'Perspective Eye', Insight into the Secrets Inside Products

Huafei Industrial Micro XCT technology has become a mature method for non-destructive testing of products. It is like installing a pair of "perspective

eyes" on the product, which can non destructively see through the interior of the product, present its internal structure in three dimensions, and

accurately identify various potential defects, such as:

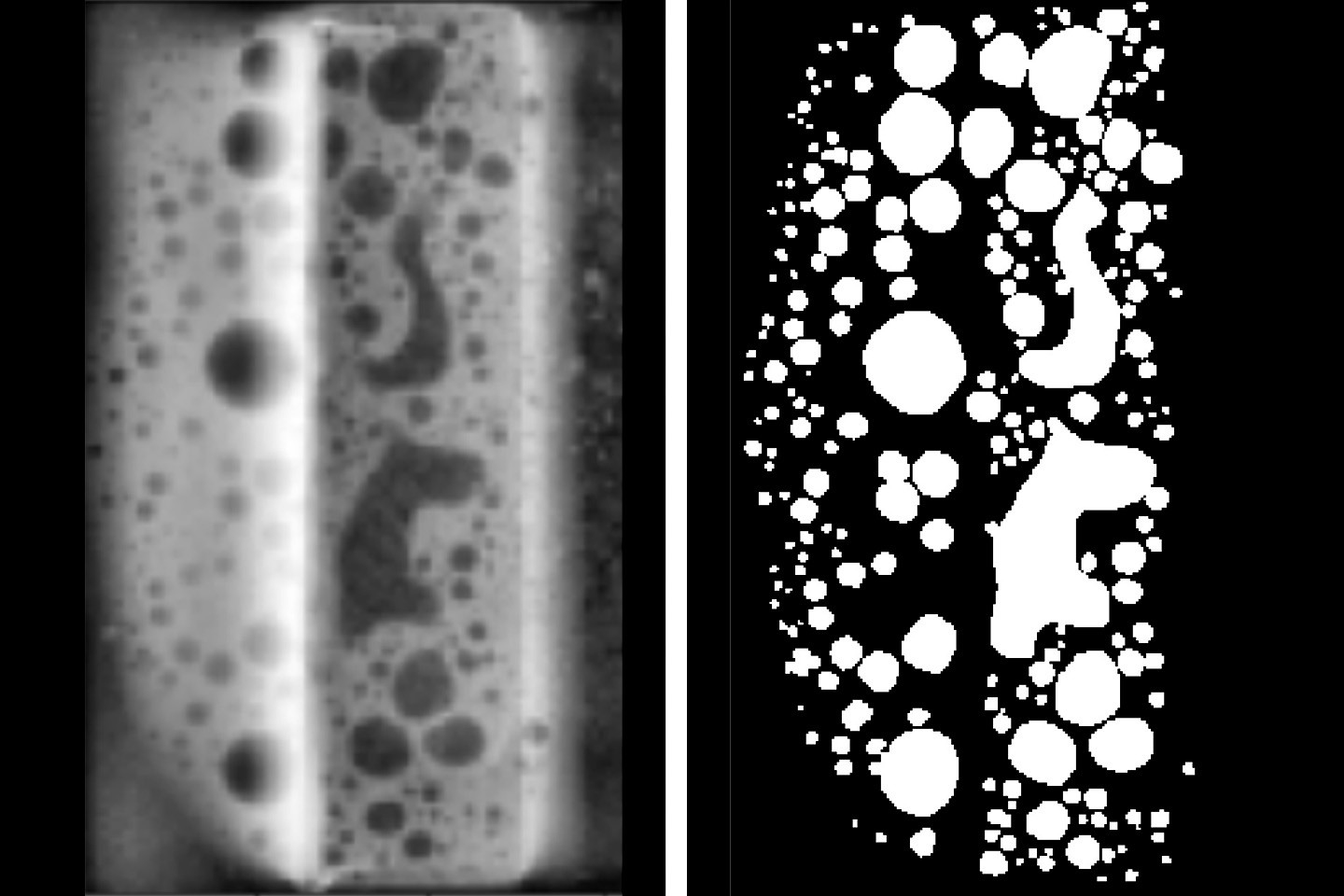

Chip resistance solder joints: Accurately detect voids, bubbles, virtual soldering, fractures, and other issues inside the solder joints to ensure

the electrical connection reliability of electronic products.

Ceramic filter: Clearly display defects such as cracks, pores, impurities, and uneven density inside the ceramic body, ensuring the performance and stability of the filter.

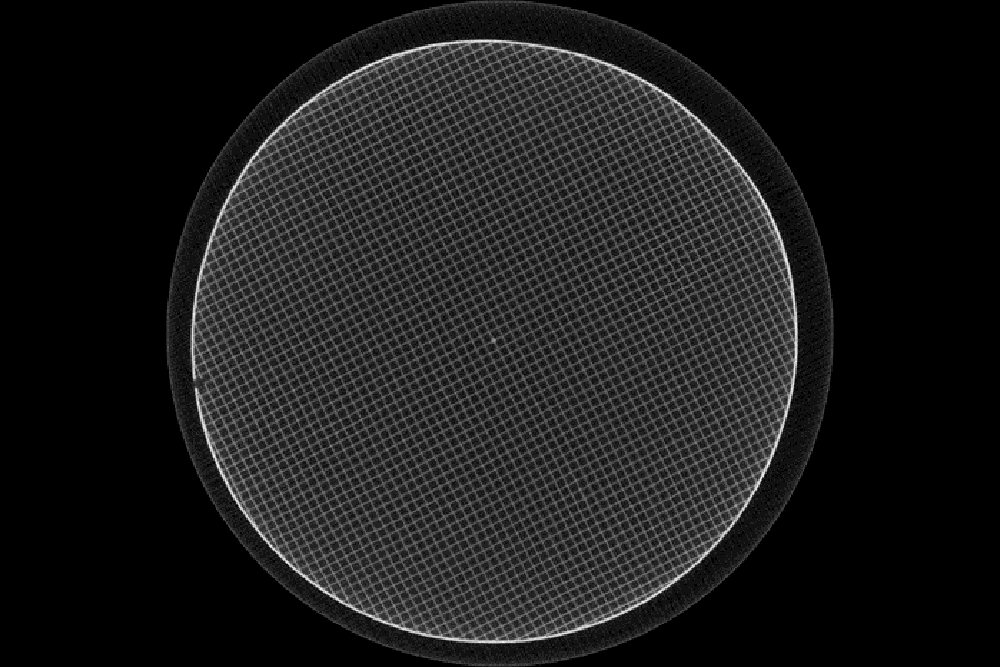

Battery: Conduct a comprehensive analysis of internal electrode misalignment, diaphragm damage, foreign object intrusion, uneven electrolyte distribution, and abnormalities to ensure the safety and service life of the battery.

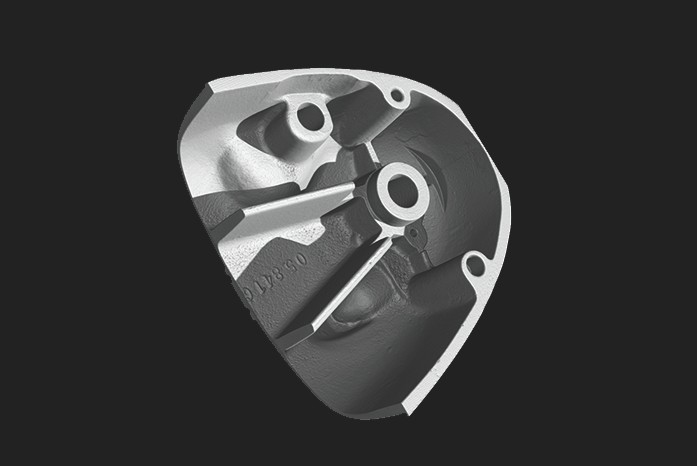

Car shift cover: effectively identify internal cracks, pores, inclusions, uneven wall thickness defects, and improve the strength and durability of car

components.

The advantages of Micro XCT go far beyond this:

Non destructive testing: Without damaging the sample, a comprehensive understanding of the internal structure of the product can be obtained,

which is suitable for precious samples or products that require subsequent analysis.

3D visualization: Generate a 3D volume model of the product, which can observe and analyze internal defects from any angle, providing more

comprehensive and intuitive information.

High spatial resolution: capable of capturing tiny defects at the micrometer level, meeting high-precision detection requirements.

Multi functional applications: In addition to defect detection, it can also perform various applications such as dimensional accuracy analysis,

porosity analysis, material uniformity analysis, geometric dimension measurement, etc.

Wide applicability: It can detect samples of various materials and sizes, from tiny electronic components to large automotive parts, and even

artworks and fossils.

Fast and efficient: The detection process is fast, and three-dimensional data is generated immediately after the measurement is completed, greatly

reducing the detection cycle.

How does Micro XCT work?

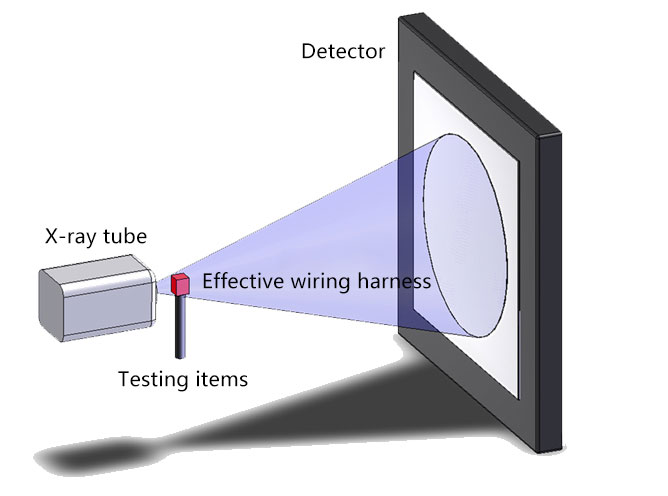

The core of Micro XCT equipment lies in the collaborative operation of X-ray tubes, detectors, and high-precision rotating tables. The tested sample is

placed on a rotating table and scanned 360 ° under X-ray irradiation. The detector records X-ray projection data from various angles, and the computer

cluster performs high-speed reconstruction on these data, ultimately generating a three-dimensional volume model of the sample. Scientists and

engineers can perform slicing analysis, defect recognition, size measurement, and other operations on 3D models through professional software, and

present the detection results in the form of cross-sectional images or 3D animations, which is convenient and fast.

Choose Micro XCT to enhance your product competitiveness

For electronic product manufacturers, ceramic product manufacturers, battery manufacturers, automotive component suppliers, and other enterprises

with high requirements for product quality, the introduction of industrial Micro XCT technology will undoubtedly greatly improve product quality,

reduce quality risks, and enhance market competitiveness.

Previous article:2D X-Ray Non destructive Testing System for IC Chips: Penetrating the Microscopic World to Ensure Core Quality

Next article:None