Application of X-ray detection equipment for internal detection of sensors

Source:H.F.XRelease time:2025-08-29 23:10:31

In modern industrial production, sensors, as an important electronic component, are widely used in various fields such as automobile manufacturing,

medical equipment, household appliances, industrial automation, etc. To ensure the high performance and reliability of these sensors, the detection

process cannot be ignored. Traditional detection methods can no longer meet the requirements for high precision and small defects, therefore, more

and more enterprises are turning to the use of X-ray detection technology.

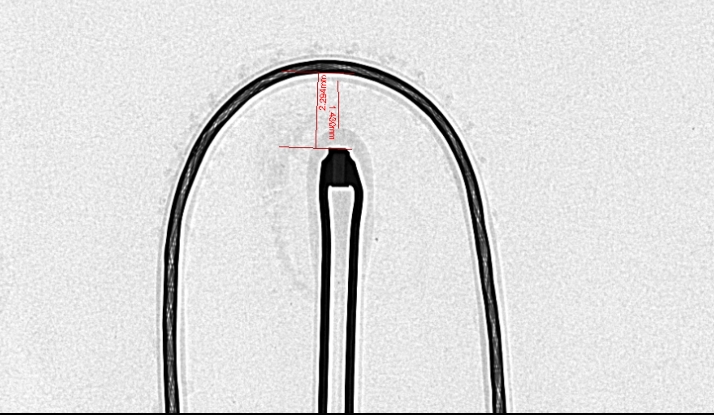

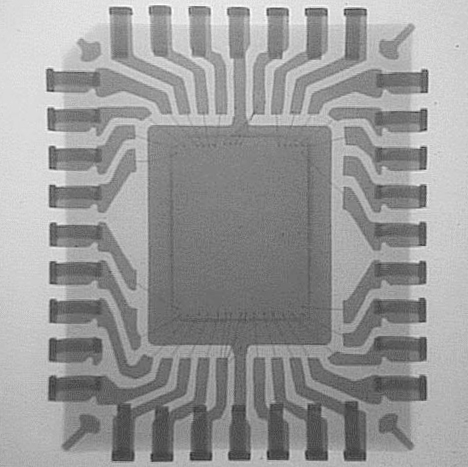

The core principle of X-ray detection technology is to use X-rays to penetrate objects and interact with atoms inside the material to form images. In the detection of sensors, X-rays can effectively penetrate the outer shell of the sensor, revealing its internal structure, welding quality, material defects, and other information. Through X-ray imaging, inspectors can quickly assess the qualification of sensors and even detect small defects that are difficult to detect with the naked eye.

X-ray detection systems typically consist of X-ray sources, detectors, image processing software, and display systems. When the radiation emitted by the X-ray source passes through the sensor, the degree of absorption and transmission of the radiation may vary due to differences in materials and densities. The detector receives the penetrating radiation and converts it into a digital signal, ultimately generating an image.

Advantages of X-ray detection sensors

1. High precision and resolution: X-ray detection can detect tiny cracks, pores, welding defects, etc. that are difficult to detect with traditional methods.

Especially when detecting sensors with small structures or complex geometric shapes, X-rays can provide ultra-high resolution and accuracy.

2. Non destructive testing: Unlike traditional mechanical cutting or other destructive testing methods, X-ray testing is a non-contact, non-destructive

testing method that can maintain the integrity of the sensor and reduce waste.

3. Rapid detection: X-ray detection equipment can complete high-quality imaging in a short period of time, greatly improving detection efficiency,

especially in large-scale production environments, which can effectively reduce downtime.

4. Comprehensiveness: X-ray inspection can not only analyze the external morphology, but also deeply explore the internal structure of the sensor,

including small parts such as welding points and wire connections, providing comprehensive data support for product quality control.

Application scenarios of X-ray detection sensors

1. Automotive manufacturing: There are various types of sensors in the automotive industry, including pressure sensors, temperature sensors, oxygen sensors, etc. X-ray inspection can ensure that the structure and circuit connections of these sensors meet the requirements, thereby improving the safety and performance of automobiles.

2. Medical equipment: In the medical field, sensors are widely used in devices such as electrocardiograms, blood glucose meters, etc. X-ray technology can effectively detect the internal circuits of these high-precision sensors, ensuring that they can provide accurate data at critical moments.

3. Home appliances: Smart home appliances use a large number of sensors, such as temperature sensors, humidity sensors, etc. X-ray detection technology can help manufacturing enterprises detect the packaging quality of sensors, ensuring their stability and long-term reliability.

4. Industrial automation: Sensors in automated production lines are responsible for monitoring the operating status of equipment, such as pressure, temperature, flow rate, etc. X-ray inspection can help detect the welding quality and internal structure of these sensors, ensuring smooth operation of the production line.

How to choose suitable X-ray detection equipment

For enterprises that require sensor detection, choosing the appropriate X-ray detection equipment is crucial. The following factors need to be

considered when selecting equipment:

1. Device resolution: High resolution X-ray devices can provide clearer and more detailed images, helping to detect small defects. It is very important

to choose high-resolution devices for small electronic products such as sensors.

2. Penetration ability: Different sensors have different materials and thicknesses, and selecting X-ray equipment with sufficient penetration ability can

ensure comprehensive and accurate detection results.

3. Software functions: The software functions that come with X-ray equipment are also important reference standards when selecting. Excellent

software can automatically analyze detection images, quickly identify defects, and generate relevant reports, greatly improving work efficiency.

4. Equipment size and adaptability: Considering the space and layout of the production line, choosing X-ray equipment with moderate size can better

integrate into the existing production environment. Meanwhile, the adaptability of the equipment, such as automatically adjusting detection

parameters, can also improve detection efficiency.

5. After sales service and technical support: The after-sales service and technical support of the equipment are crucial. Ensuring that equipment

manufacturers can provide timely maintenance, technical support, and equipment upgrade services is the foundation for ensuring the stable

operation of production lines.

Challenges and Solutions for Implementing X-ray Inspection in Enterprises

Although X-ray detection technology has significant advantages in sensor detection, enterprises may also encounter some challenges in the

implementation process. Here are a few common problems and solutions:

1. Equipment cost: The initial investment in X-ray detection equipment is relatively high, which may put pressure on some enterprises. The solution

is to choose equipment with high cost-effectiveness, or to share costs through leasing, cooperation, and other means.

2. Operation training: X-ray equipment operation requires professional technicians to operate, especially in image processing and defect analysis.

Therefore, companies should invest time and resources in employee training to ensure that operators can proficiently master equipment usage and

analysis skills.

3. Radiation safety: X-ray equipment generates a certain amount of radiation, so it is necessary to strictly comply with relevant safety standards.

Enterprises should choose equipment that meets safety standards when purchasing equipment and ensure that operators wear necessary protective

equipment.

The X-ray detection sensor is an important means to improve product quality and detection accuracy. By selecting appropriate equipment and

technology, enterprises can ensure product qualification rate, improve production efficiency, and reduce unnecessary waste in the sensor production

process. With the continuous advancement of technology, the application of X-rays in the field of sensors will become more common, bringing new

changes to production and quality control in various industries.

Recommend

-

Application of X-ray detection equipment for internal detection of sensors

With the development of modern technology, sensors have been widely used in various industries, incl

2025-06-30 -

Application of X-ray detection equipment for internal detection of sensors

X-Ray detection fuse is a non-destructive testing technology that uses X-rays to penetrate an object

2025-06-30 -

Application of X-ray detection equipment for internal detection of sensors

X-ray inspection of joints is a method of internal inspection using X-ray technology, widely used in

2025-06-30 -

Application of X-ray detection equipment for internal detection of sensors

In the production and application process of LED light strips, quality control has always been a foc

2025-06-30 -

Application of X-ray detection equipment for internal detection of sensors

In modern industrial production, product quality is one of the core elements of enterprise competiti

2025-06-26