How to ensure the quality of wire harness with X-ray inspection equipment

Source:H.F.XRelease time:2025-08-29 23:13:54

In the complex context of modern industry, wiring harnesses are like the nervous system of the human body, distributed in various key fields such as

automobiles, aerospace, medical equipment, and communication systems. They are responsible for transmitting electricity and signals, and are the

cornerstone of stable operation of machinery and equipment. Although the wiring harness is small, its internal structure is intricate and complex. Any

minor flaw can lead to serious malfunctions and even cause safety accidents. Therefore, how to ensure the quality and reliability of wire harnesses

has become an important issue that manufacturing enterprises cannot ignore.

Traditional wire harness detection methods often rely on manual visual inspection or simple electrical testing. These methods may be effective for surface defects, but they are inadequate for the "hidden diseases" hidden inside the wire bundle. For example, problems such as poor crimping, virtual soldering of solder joints, wire breakage, and damaged shielding layers inside connectors are difficult to detect with the naked eye, and electrical testing may not accurately locate the defects. These potential quality hazards are like ticking time bombs, which can trigger a product quality crisis at any time.

Faced with increasingly stringent quality standards and market competition, enterprises urgently need a more efficient and accurate detection method to "see through" the interior of wire harnesses and uncover hidden defects. The emergence of X-ray inspection equipment has brought

new breakthroughs to the quality control of wire harnesses.

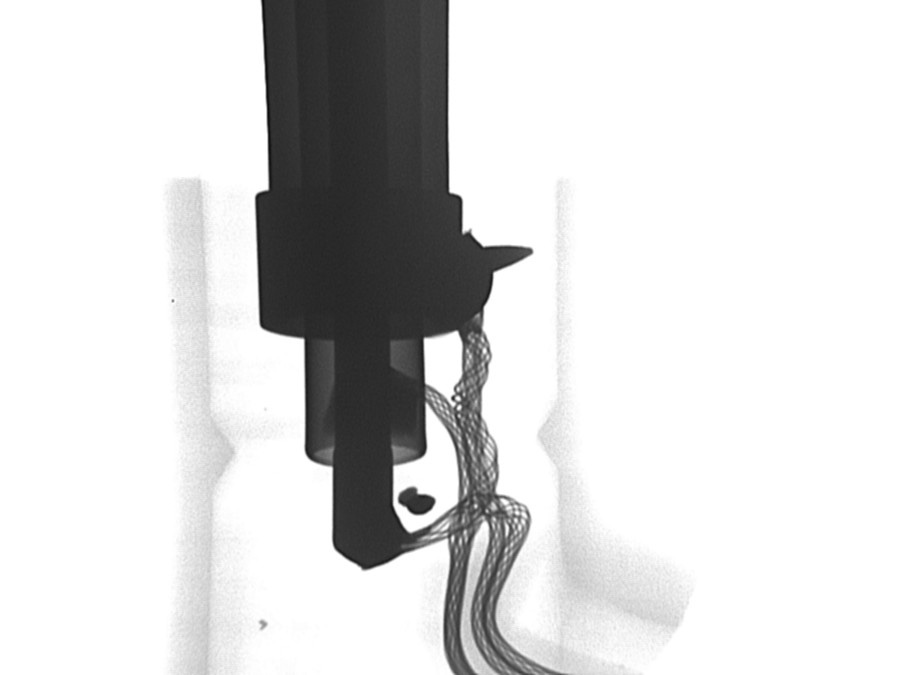

X-rays, as the name suggests, have strong penetrating power. When X-rays are irradiated onto the wire harness, components of different materials and densities absorb X-rays to varying degrees, resulting in a contrast between light and dark images. By analyzing these images, we can clearly 'see' the internal structure of the wiring harness, such as:

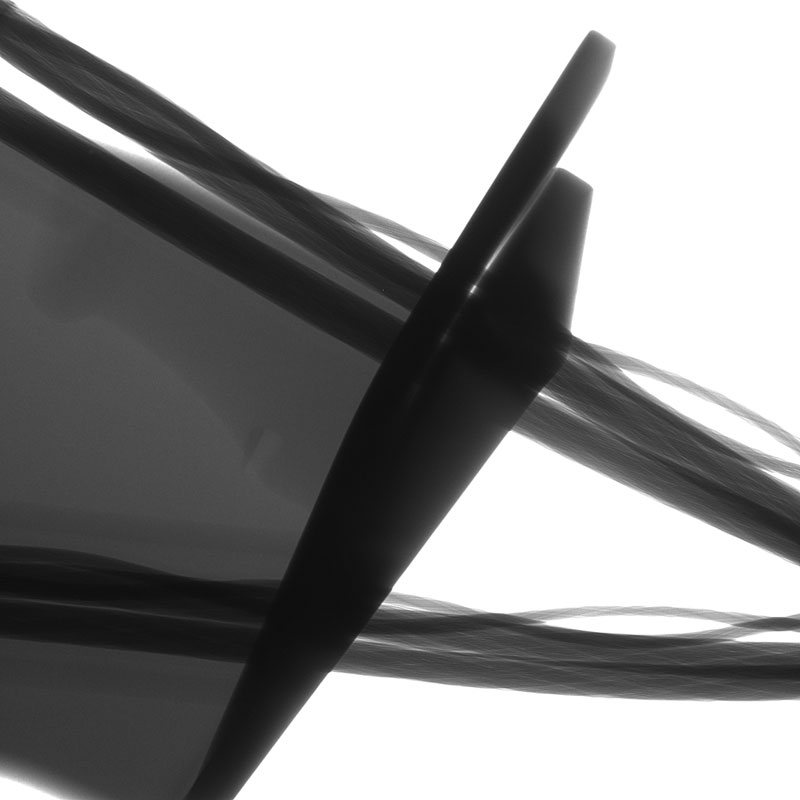

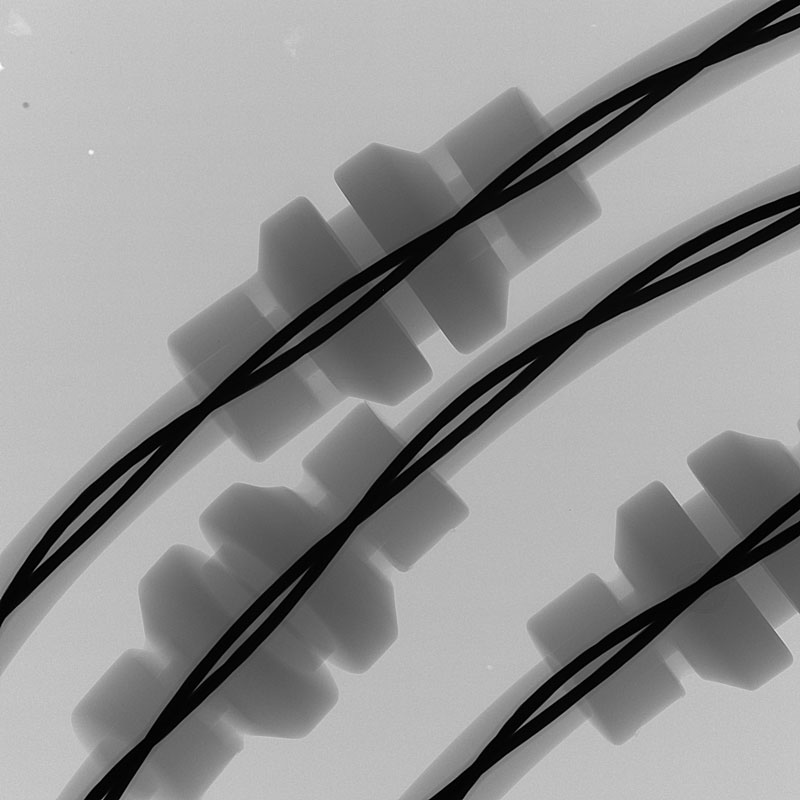

-Quality of connector and terminal crimping: X-rays can clearly show the crimping situation of the internal terminals of the connector, identify whether

there are problems such as improper crimping, crimping deformation, or even missing terminals. For multi pin connectors, observing from different

angles by rotating the sample stage can effectively avoid the difficulty of image analysis caused by component overlap.

-Solder joint quality: Whether it is solder joints in terminals or wire harnesses, X-rays can effectively detect defects such as virtual soldering, empty

soldering, insufficient solder, bubbles, etc. CT scanning technology goes further and can provide cross-sectional images of the solder joint area,

allowing for a clear view of the details inside the solder joint.

-Internal defects of wire: X-rays can penetrate the insulation layer and detect whether there are broken wires, short circuits, conductor damage,

shielding layer damage, and other issues inside the wire. Even with metal shielded wires, high penetration X-ray sources can ensure clear imaging.

-Quality of injection molded parts: For wire harnesses with injection molded connectors, X-rays can detect defects such as bubbles, cracks, and

impurities inside the injection molded parts, ensuring their integrity and sealing.

Compared with traditional detection methods, X-ray detection technology has unparalleled advantages:

-Non destructive testing: X-ray testing does not require dismantling the wiring harness and will not cause any damage to the tested sample.

-Internal defect visualization: X-rays can penetrate materials and directly present the internal structure and defects of the wiring harness, achieving

a "perspective eye" effect that traditional visual inspection and electrical testing cannot achieve.

-High detection efficiency: X-ray detection is fast and can quickly scan the entire wire harness, greatly improving detection efficiency and meeting the

needs of mass production.

-Objective and reliable results: X-ray images can be digitally processed and analyzed, resulting in more objective and accurate detection results,

reducing human errors.

In today's pursuit of excellent quality, the quality of wire harnesses is directly related to the performance and safety of end products. X-ray detection technology provides strong support for wire harness quality control with its unique advantages. For enterprises that require wire harness testing, introducing X-ray inspection equipment can not only effectively improve product quality and reduce defect rates, but also enhance customer trust, improve brand competitiveness, and ultimately gain an advantage in the fierce market competition.

Previous article:None

Next article:Application of X-ray detection equipment for internal detection of sensors

Recommend

-

How to ensure the quality of wire harness with X-ray inspection equipment

With the development of modern technology, sensors have been widely used in various industries, incl

2025-06-30 -

How to ensure the quality of wire harness with X-ray inspection equipment

X-Ray detection fuse is a non-destructive testing technology that uses X-rays to penetrate an object

2025-06-30 -

How to ensure the quality of wire harness with X-ray inspection equipment

X-ray inspection of joints is a method of internal inspection using X-ray technology, widely used in

2025-06-30 -

How to ensure the quality of wire harness with X-ray inspection equipment

In the production and application process of LED light strips, quality control has always been a foc

2025-06-30 -

How to ensure the quality of wire harness with X-ray inspection equipment

In modern industrial production, product quality is one of the core elements of enterprise competiti

2025-06-26