Application of X-ray Detection in Aerospace Industry

Source:H.F.XRelease time:2025-07-02 22:37:33

With the rapid development of the aerospace industry, the requirements for component quality and safety assurance are becoming increasingly high.

Although there are various detection methods, X-ray detection has gradually won the favor of the industry with its unique advantages. Perhaps you

have heard of X-ray inspection, but do you truly understand its application prospects in the aerospace industry? This article will take you on a journey

through X-ray technology, delving into how X-ray detection technology can shine in the high-precision field of aerospace, helping to promote safety

and innovation. The X-ray detection system of Zhicheng Jingzhan brand will comprehensively reveal its multiple applications and advantages.

1、 Overview of the basics of X-ray detection

X-ray testing, also known as X-ray inspection, is a non-destructive testing technique that uses X-rays to penetrate objects and form images based on

the density differences of different substances. In the aerospace industry, X-ray inspection can provide non-destructive detection of internal defects,

ensuring the integrity and safety of products. Although it may sound fancy, the principle behind it is actually quite simple: high-energy X-rays are

absorbed and penetrated to varying degrees when passing through an object, forming images that can be observed with the naked eye or digital

imaging devices. So, don't misunderstand, this is not just a magical technology that only appears in science fiction movies.

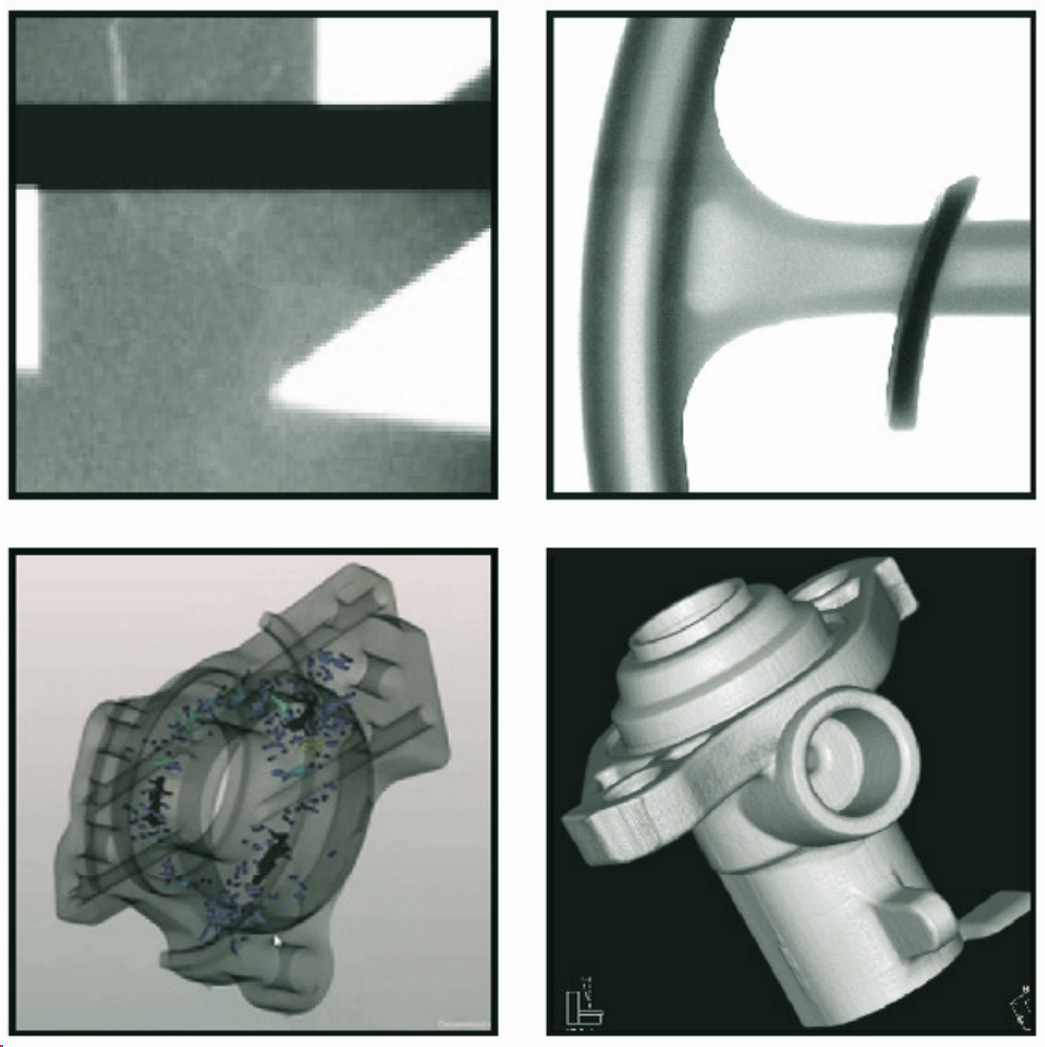

2、 Used for material defect detection

The materials used in the aerospace field generally have characteristics such as high strength, lightweight, and high temperature resistance, therefore,

the detection of material damage and defects is crucial. Although traditional detection methods such as visual inspection, ultrasound, and infrared

detection have their own advantages, X-ray detection has unparalleled superiority due to its unique ability to perceive tiny internal defects. Whether it

is poor casting and forging during the manufacturing process, or fatigue and corrosion during use, X-ray inspection can provide in-depth exploration.

The X-ray detection system developed by Zhicheng Jingzhan is fully capable of meeting the strict requirements of the industry and providing high-

precision defect detection services.

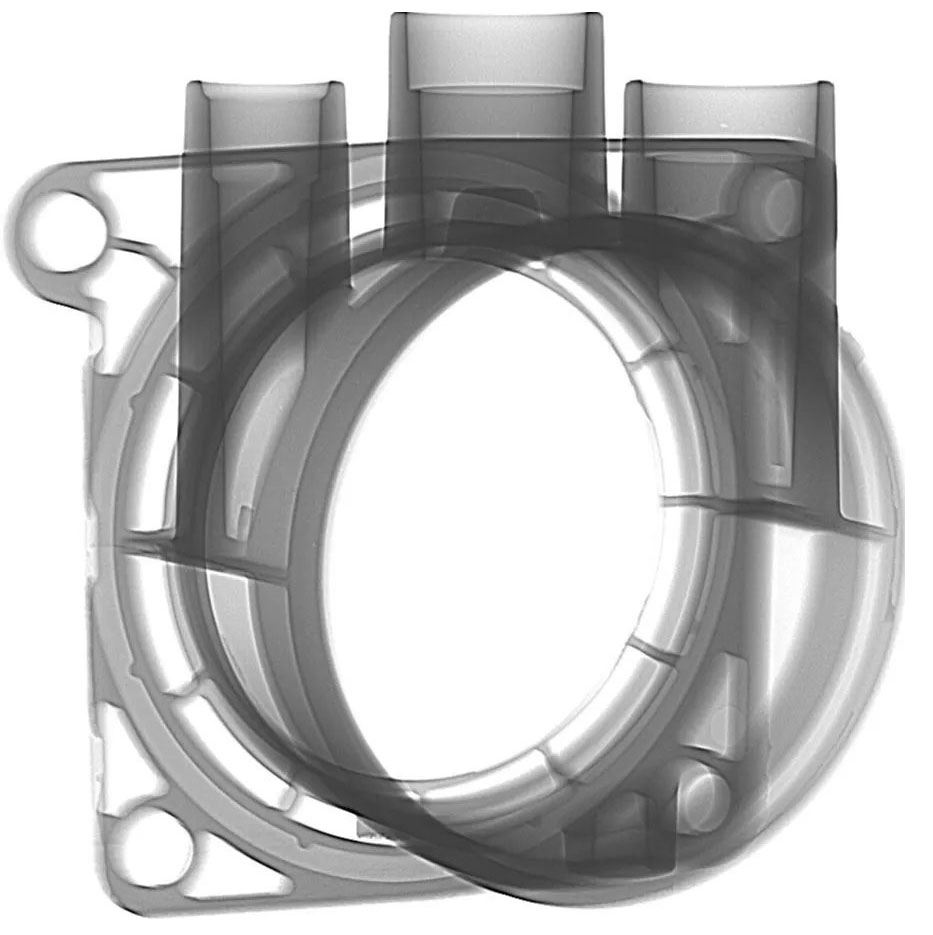

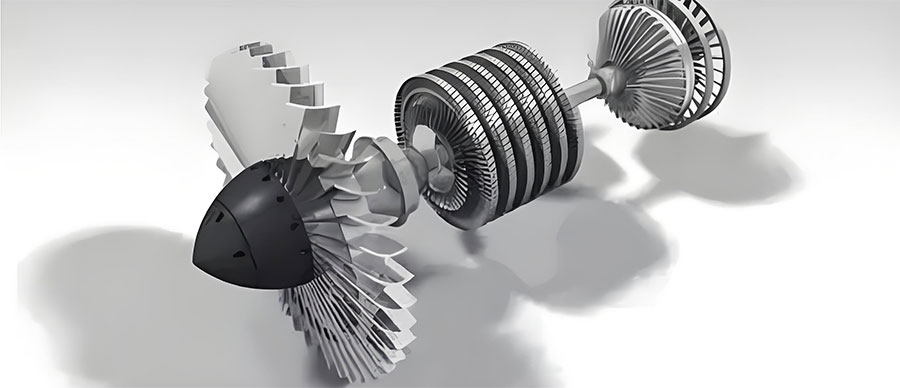

3、 A powerful tool for whole machine assembly inspection

In the aerospace industry, the assembly accuracy of components has a crucial impact on the overall performance of the aircraft. Through X-ray

inspection, the internal structure and relative position of the assembled components can be clearly viewed, effectively checking the welding quality,

bolt tightening, and circuit board connectivity. Whether it's satellites, airplanes, or rockets, these complex and precise engineering integrated systems

cannot do without the assistance of X-ray detection. Especially for those non removable assembly components, X-ray inspection can even be said to

be the "ultimate weapon", and all the "little secrets" of electronic devices will be nowhere to hide.

4、 Assist in composite material testing

With the widespread use of composite materials in the aerospace industry, how to effectively detect these composite materials has become a new

challenge. Unlike traditional metal materials, defects such as fiber breakage and interlayer debonding in composite materials are difficult to detect

through traditional testing methods. And X-ray detection can precisely solve this problem. Through high-resolution imaging technology, it can clearly

display the internal structure of composite materials, making potential defects clear at a glance. Zhicheng Jingzhan's X-ray detection system has

unique technological advantages in composite material detection, allowing the high performance of composite materials to be fully utilized, ensuring

the safe operation of aircraft, satellites and other equipment.

5、 Efficient detection shortens the research and development cycle

The development cycle of aerospace products is usually long, and the failure of any component may prolong the entire project schedule. X-ray

detection has played an important role in shortening the development cycle with its efficient and accurate detection speed. By using real-time and

non-destructive testing methods, problems in manufacturing can be detected and corrected in a timely manner, thereby reducing the time cost of

repeated testing and rework. The X-ray detection system developed by Zhicheng Jingzhan not only improves work efficiency, but also provides

important data support for product development, effectively helping the R&D team accelerate innovation.

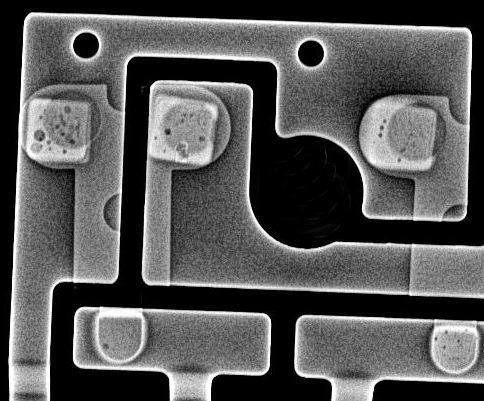

6、 Data analysis and intelligent detection

With the development of data analysis and artificial intelligence, X-ray detection technology is no longer just a simple detection tool, but has become

an intelligent detection platform. By combining advanced image processing algorithms and big data analysis, the X-ray detection system can not only

automatically identify and classify defects, but also predict the service life of materials and parts. This intelligent detection system not only improves

the accuracy and efficiency of detection, but also provides valuable data support for the continuous improvement of product quality. Zhicheng

Jingzhan has already taken the lead in this field, helping aerospace companies transition from traditional manufacturing to intelligent manufacturing

through its independently developed intelligent detection system.

7、 Environmental Protection and Humanized Design

In terms of environmental protection and humanized design, X-ray detection also has significant advantages that cannot be ignored. The X-ray

detection equipment of Zhicheng Jingzhan adopts the design concept of low radiation and high efficiency, reducing the impact on the environment

and the health of operators. Meanwhile, the user-friendly interface design and intelligent operation process enable technicians to complete detection

tasks more conveniently and quickly. This type of equipment not only improves production efficiency, but also provides a safe and friendly working

environment for employees.

Previous article:None

Next article:None