X-ray detection applied to sensors

Source:H.F.XRelease time:2025-08-29 22:26:38

With the development of modern technology, sensors have been widely used in various industries, including medical, industrial, safety, automotive,

aerospace and other fields.

A sensor is a detection device that can sense the information being measured and convert it into electrical signals or other required forms of

information output according to certain rules, in order to meet the requirements of information transmission, processing, storage, display, recording,

and control.

The existence and development of sensors have given objects senses such as touch, taste, and smell, making them come to life. We can compare

sensors to human facial features, which can be used to perceive the outside world and make corresponding actions.

At this point, we have a clear understanding of the significance of sensors. The quality of natural sensors is of utmost importance. Currently, XRAY

testing is commonly used for non-destructive testing of sensors. Next, we will explain in detail.

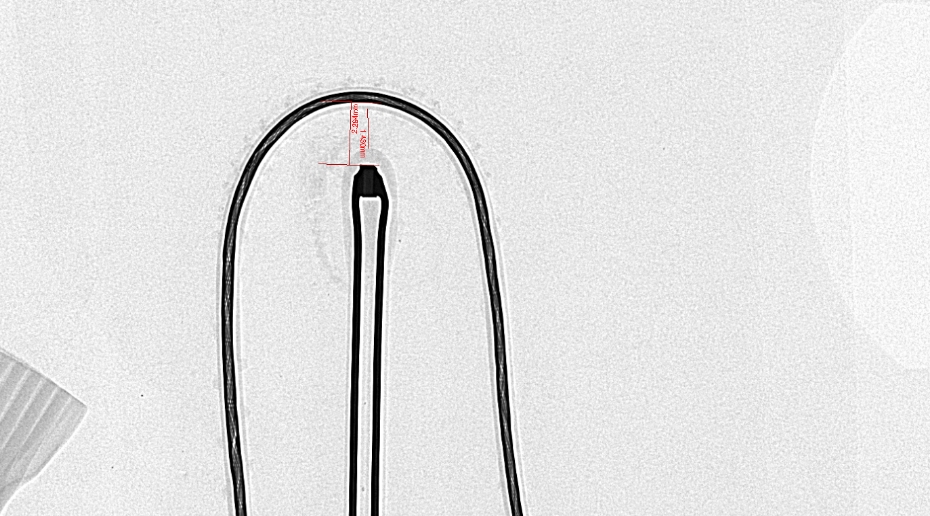

Firstly, let's understand the working principle of X-ray detection sensors. Xray, X-rays are a type of radiation with high-energy electromagnetic wave

characteristics and strong penetrating power. When X-rays pass through an object, they interact with matter, resulting in absorption and scattering

phenomena. These phenomena can be captured by X-ray detection sensors, and through a series of transformations and processing, the internal

structural information of the object can be presented in the form of images. Specifically, the areas with more absorption appear as darker parts in the

image, while the areas with more scattering appear as brighter parts. Through this method, we can clearly see the structure and details inside the

object.The advantages of X-ray detection sensors lie in their non-destructive nature, high precision, and high efficiency.

Firstly, due to the strong penetrating power of X-rays, they can be used for detection without damaging objects, which is crucial for objects that

require integrity.

Secondly, X-ray detection sensors can generate high-resolution images that clearly display the details and structure inside objects, providing strong

support for analysis and judgment.

Finally, X-ray detection sensors have high detection efficiency and can detect a large number of objects in a short period of time, greatly improving

detection speed and efficiency.

In the industrial field, X-ray detection sensors also have wide application value. It can be used to inspect internal defects of products, such as cracks,

pores, and uneven materials, to ensure the quality and safety of the product.

X-ray detection sensors play a crucial role in industries such as aerospace, automotive manufacturing, nuclear energy, and petrochemicals. It can not

only perform quality inspection on components, but also be used to measure parameters such as thickness and density of objects, providing

important basis for quality control in the production process.

The new generation of X-ray detection equipment has undergone comprehensive upgrades in hardware and software, improving detection accuracy

and efficiency. At the same time, some devices also have the feature of multifunctional integration, which can perform multiple detection tasks

simultaneously, further improving the utilization and efficiency of the equipment.

Previous article:X-RAY detection applied to fuse defects

Next article:None

Recommend

-

X-ray detection applied to sensors

X-Ray detection fuse is a non-destructive testing technology that uses X-rays to penetrate an object

2025-06-30 -

X-ray detection applied to sensors

X-ray inspection of joints is a method of internal inspection using X-ray technology, widely used in

2025-06-30 -

X-ray detection applied to sensors

In the production and application process of LED light strips, quality control has always been a foc

2025-06-30 -

X-ray detection applied to sensors

In modern industrial production, product quality is one of the core elements of enterprise competiti

2025-06-26 -

X-ray detection applied to sensors

In modern industrial production, sensors, as an important electronic component, are widely used in v

2025-06-26