X-Ray detection applied to improve the quality control of LED light strips

Source:H.F.XRelease time:2025-08-29 23:06:09

In the production and application process of LED light strips, quality control has always been a focus of attention in the industry. However, with the

increasing market demand and technological advancements, traditional quality inspection methods are no longer able to meet the high standards

of quality requirements. At this point, X-Ray detection technology, with its high efficiency and precision, has gradually become the preferred solution

for quality control of LED light strips. Many manufacturers face the challenge of ensuring the safety and reliability of their products, and X-Ray testing

can effectively solve these problems, bringing competitive advantages to enterprises.

The basic principle of X-ray detection

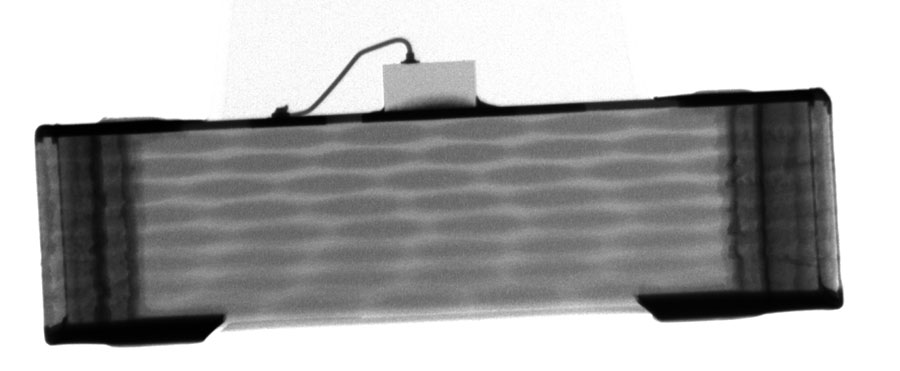

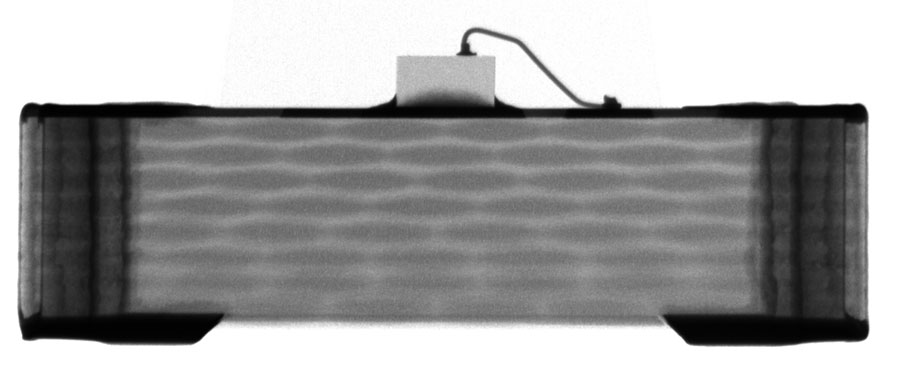

X-Ray testing is a non-destructive testing (NDT) technique that utilizes the characteristic of X-rays penetrating materials to examine the internal

structure of objects. For LED light strips, this technology can identify welding defects, equipment damage, and even internal short circuits. X-Ray

detection can generate detailed images that display the true state of the circuit board and components of the light strip. According to data, using

X-Ray technology can increase product defect detection rates by 15% -30%. In the production process of LED light strips, common defects can be

quickly located through X-Ray technology, which can more effectively improve production efficiency.

Advantages of X-Ray Inspection in LED Light Bar Quality Control

X-Ray detection technology has demonstrated numerous advantages in the quality control of LED light strips. It can provide high-resolution imaging,

visualize small defects, and greatly improve the accuracy of detection. Compared with traditional methods, X-ray detection has higher efficiency.

Statistical data shows that after implementing X-ray testing, the qualification rate of products has increased by 20%, and the detection rate of

non-conforming products has significantly increased. This is particularly important for the fiercely competitive LED industry, as it can effectively

reduce rework costs and customer credit risks. At the same time, the non-destructive characteristics of X-Ray testing technology also enable

manufacturers to complete testing without damaging the product, ensuring the integrity of subsequent use.

How to Implement X-Ray Inspection

Before implementing X-Ray testing, companies need to be fully prepared. Choose appropriate equipment to ensure it meets the requirements of LED

light strip detection. Normally, X-ray equipment needs to have high-resolution and fast imaging capabilities in order to detect problems in a timely

manner. Professional training is needed for staff to master the skills of equipment operation and troubleshooting, in order to improve detection

efficiency and accuracy. A successful case is a well-known LED manufacturing enterprise that established a dedicated quality inspection team after

introducing X-Ray testing to ensure standardization and efficiency of the testing process, thereby improving overall production quality. Enterprises

should also regularly review testing data, analyze potential issues, and continuously optimize production processes.

The Future Trends of X-Ray Detection

With the continuous maturity of technology, the application prospects of X-Ray detection in the quality control of LED light strips are broad. In the future, X-Ray technology will be combined with artificial intelligence (AI) to form a more intelligent detection system that enhances data analysis capabilities through machine learning, thereby achieving more efficient quality control. With the increasing demand of customers for product quality, X-Ray testing will become the standard in the LED industry. While complying with national and international quality standards, enterprises need to consider the comprehensive integration of X-Ray technology in internal management, further improving the transparency and sense of responsibility of the production process. Industry experts predict that gradually implementing X-Ray detection technology will enable enterprises to have stronger competitiveness in product quality assurance.

Recommend

-

X-Ray detection applied to improve the quality control of LED light strips

With the development of modern technology, sensors have been widely used in various industries, incl

2025-06-30 -

X-Ray detection applied to improve the quality control of LED light strips

X-Ray detection fuse is a non-destructive testing technology that uses X-rays to penetrate an object

2025-06-30 -

X-Ray detection applied to improve the quality control of LED light strips

X-ray inspection of joints is a method of internal inspection using X-ray technology, widely used in

2025-06-30 -

X-Ray detection applied to improve the quality control of LED light strips

In modern industrial production, product quality is one of the core elements of enterprise competiti

2025-06-26 -

X-Ray detection applied to improve the quality control of LED light strips

In modern industrial production, sensors, as an important electronic component, are widely used in v

2025-06-26