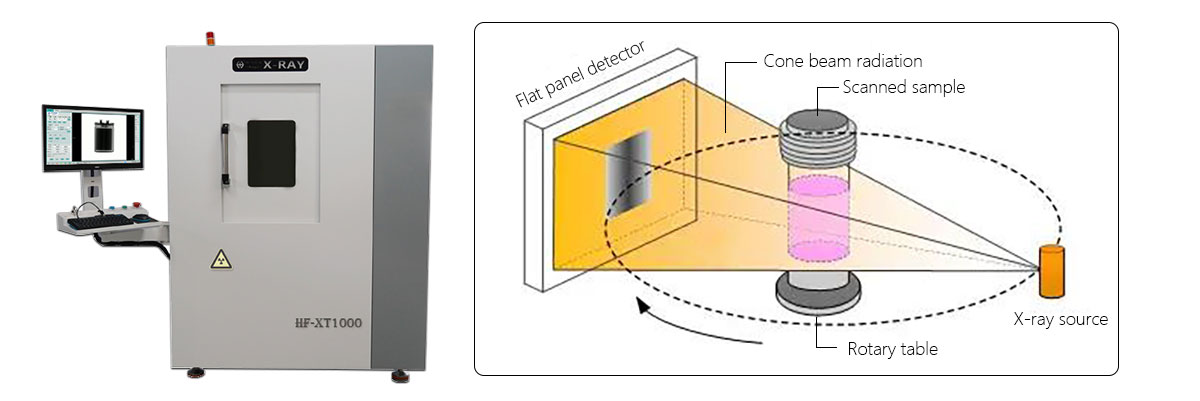

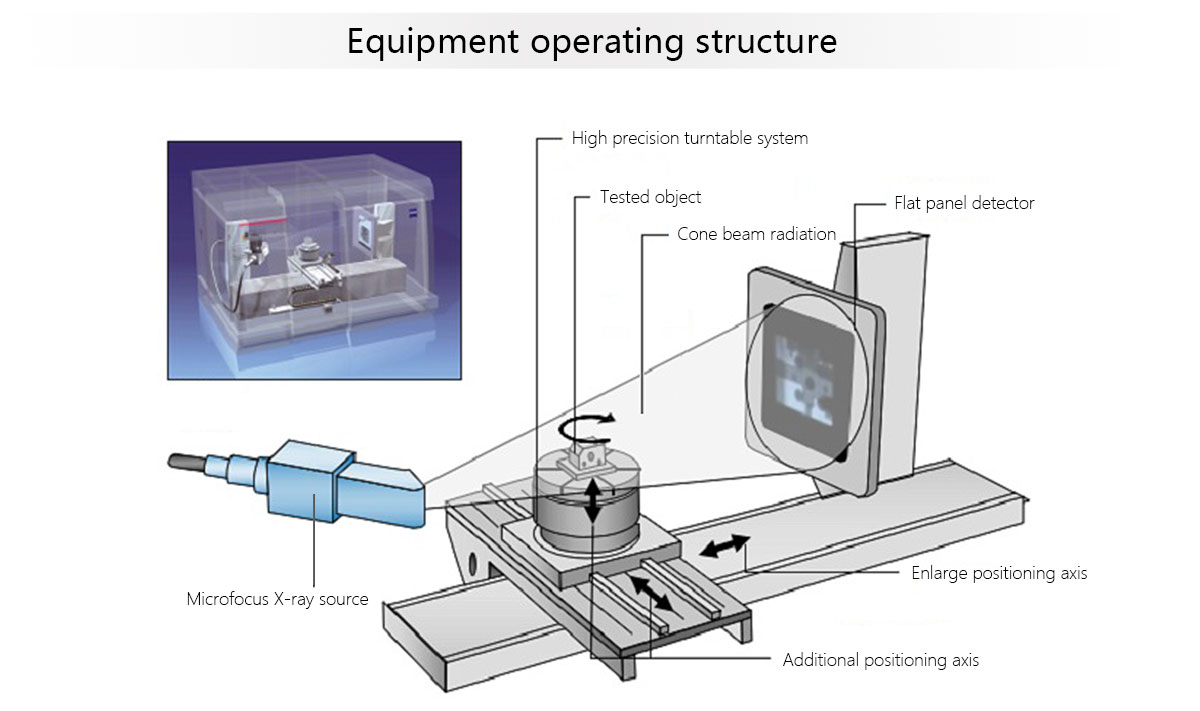

Equipment principle:

1.Non destructive testing of the internal structure of the object being tested by utilizing the penetrability of X-rays and the absorption and scattering characteristics of substances towards X-rays;

2.The X-rays attenuated by the object reach the high-resolution image flat panel detector and are digitally converted to form high-definition three-dimensional grayscale images;

3.The data processing system processes and analyzes images to accurately determine whether there are defects, foreign objects, structural abnormalities, and other adverse issues inside the object;

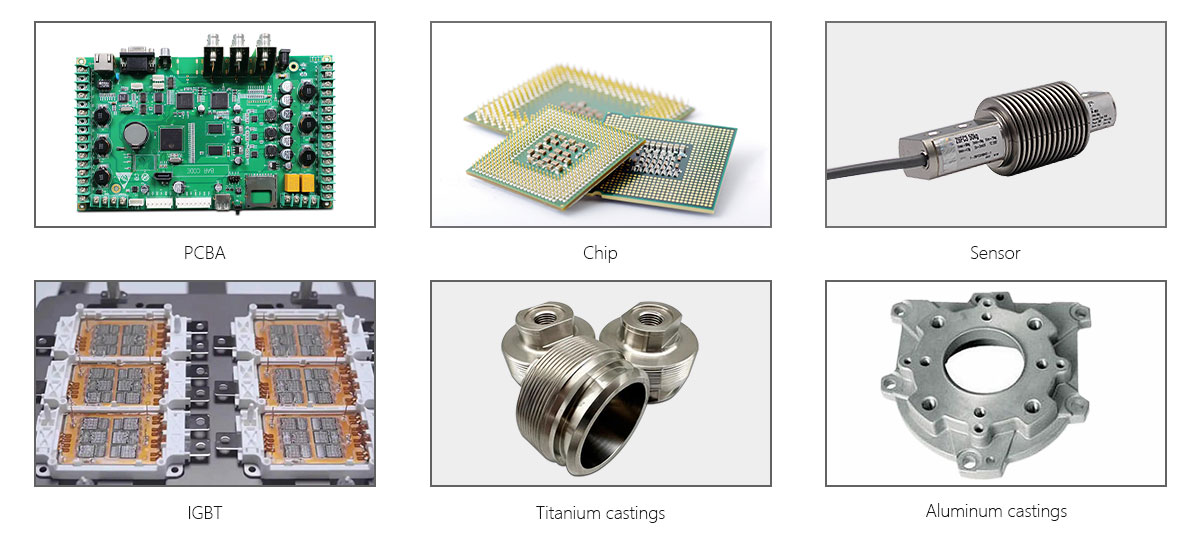

Application scope:

1.Mainly used for testing PCBA, plastics, ceramics, optical components, small titanium castings, aluminum castings, etc.:

2.Suitable for small chips IGBT、 Sensors, relays, fuses, micro motors (MEMS, MOEMS), cables and plugs, etc;

3.Inspection of SMT surface packaging components such as POP, BGA, QFN, QFP, DIP, IC, etc; Semiconductor testing such as TSV, Flipchip, Copper Pillar, etc;

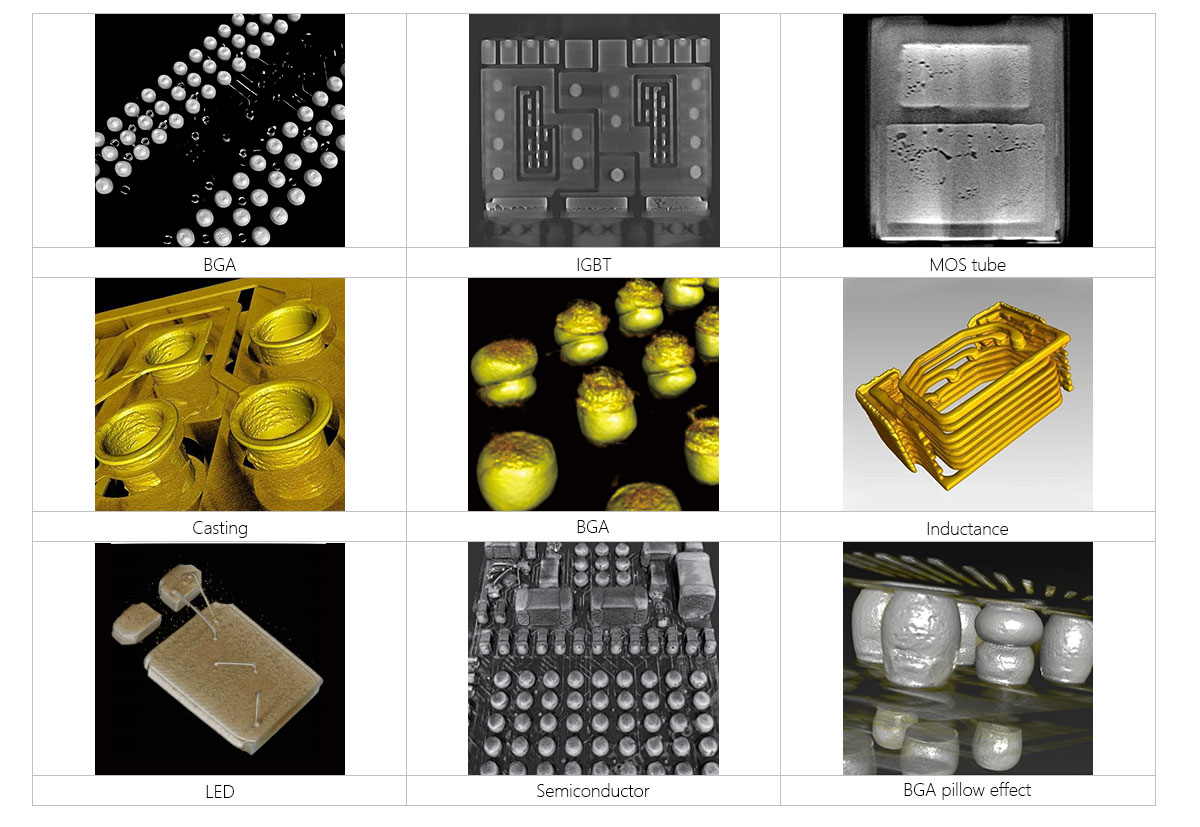

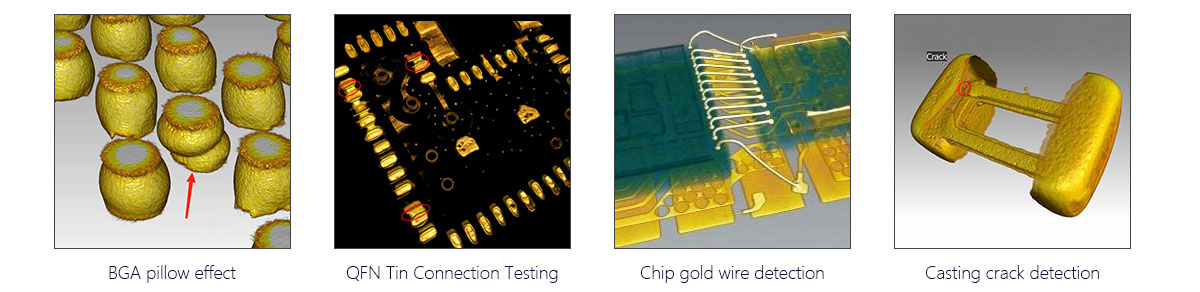

Test case:

Functional Features:

Functional features:

1.Our self-developed super-resolution fusion algorithm generates omnidirectional 3D data, with a fastest imaging time of 4 seconds. The generated 3D reconstruction data can be sliced in any direction, making it convenient for defect recognition;

2.Innovative combination of deep learning algorithms, built-in dedicated defect detection model, often significantly improves accuracy for defects such as small bubbles and pin micro short circuits;

3. Supports the detection of packaged components such as BGA, PTH, IGBT, etc., and can identify various defects such as bubbles, solder heights, open circuits, empty soldering, and offset;

4. Ultra high definition 3D rendering effect, supporting ROI area setting, layer by layer display, brightness enhancement, histogram adjustment of transparency and color, making defect viewing more convenient and intuitive;

5. The maximum geometric magnification can reach 2000X, and the defect detection capability is less than 1um;

6. Unique automatic tracking technology ensures that the detection area is at the center of the image when the detector tilts or rotates;

7. Equipped with innovative self-developed intelligent detection software, new image enhancement processing, and preset filter algorithms;

8. Barcode information association detection results, supporting integration with MES system;

9. AI intelligent detection algorithms can be customized according to users' actual needs;

10. Fast programming, guided detection module editing, simple and efficient;

11. Jigsaw navigation function, scanning each area of the sample, automatically stitching to generate the entire image, and can be used as a navigation image;

12. Real time monitoring of radiation values, safety interlock, automatic shutdown of radiation sources in idle state;

Detection effect: