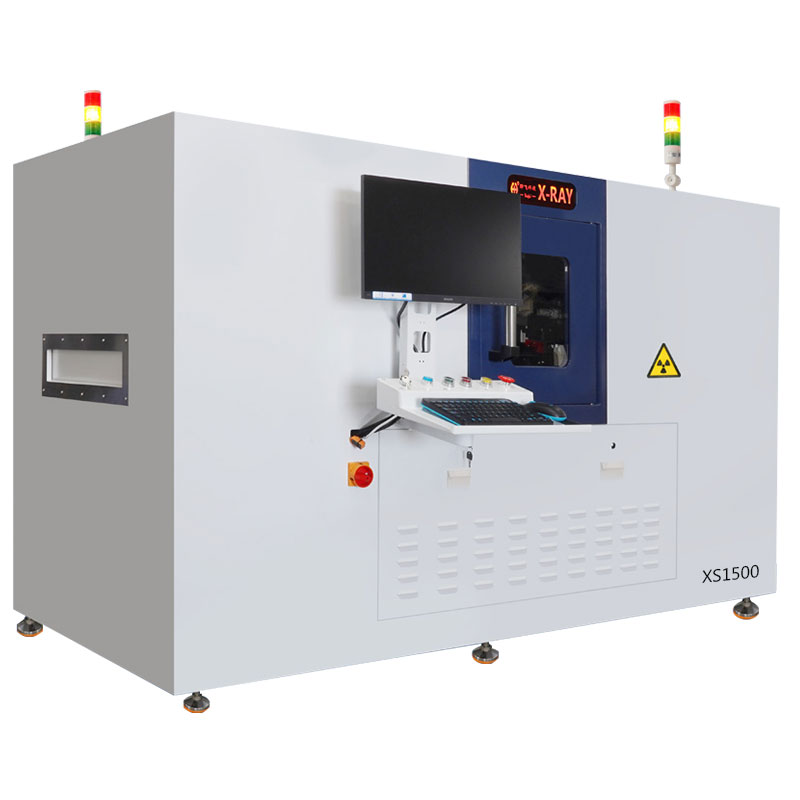

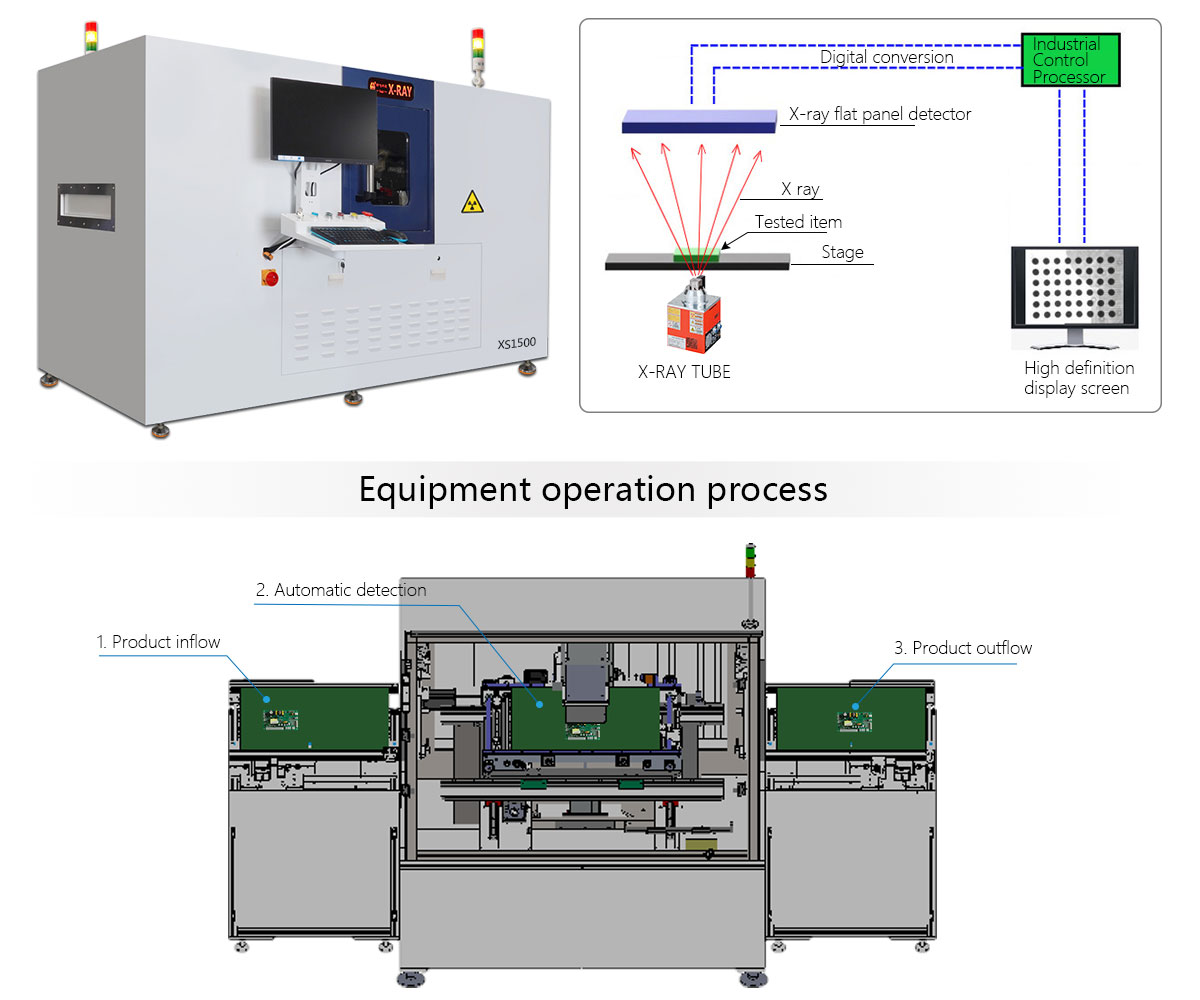

Equipment principle:

1.By utilizing the penetrability of X-rays and the absorption and scattering characteristics of substances towards X-rays, non-destructive testing of the internal structure of the object being tested has been achieved;

2.X-rays attenuated by objects reach high-resolution image flat panel detectors and undergo digital conversion to form high-definition two-dimensional or three-dimensional grayscale images;

3.The data processing system processes and analyzes images to accurately determine whether there are defects, foreign objects, structural abnormalities, and other adverse issues inside the object;

1.The track type transmission system uses chain transmission for the guide rail, with strong load-bearing capacity. The width of the transmission guide rail can be adjusted within a large range, which can better meet the testing needs of different products;

2.It can be connected to the production line for high-capacity fully automatic online inspection, with functions such as automatic feeding, automatic detection, automatic sorting, and marking of defective products;

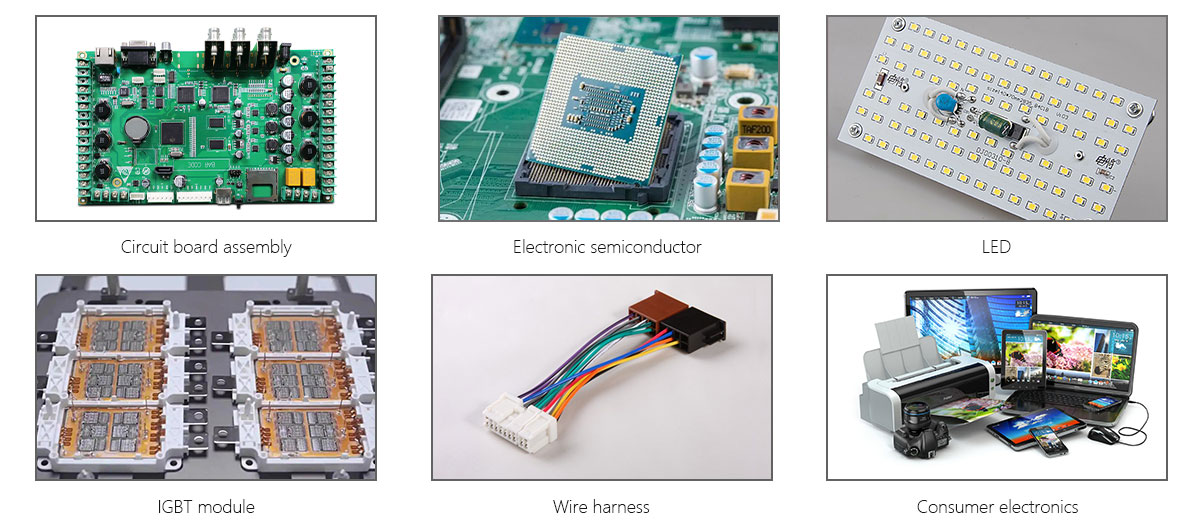

Application scope:

1.Mainly used in fields such as automotive electronics, energy electronics, home appliance electronics, consumer electronics, semiconductors, die-casting, etc;

2.Suitable for testing SMT mounting, BGA solder joints, packaged devices, semiconductor components, precision metal castings, injection molded products, etc;

3.Suitable for PCBA, chips LED、IGBT、 Wires, sensors, fuses, QFNs, MOSFETs FPC、 Non destructive testing of new energy lithium batteries, power cords, diodes, capacitors, automotive parts, aviation parts, etc;

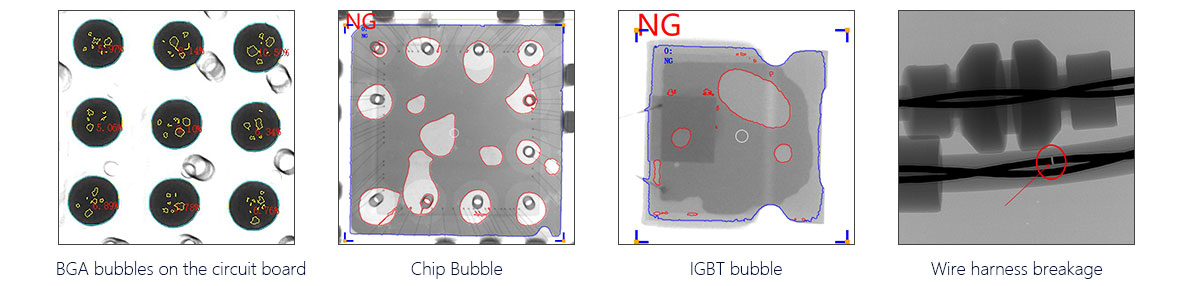

Test case:

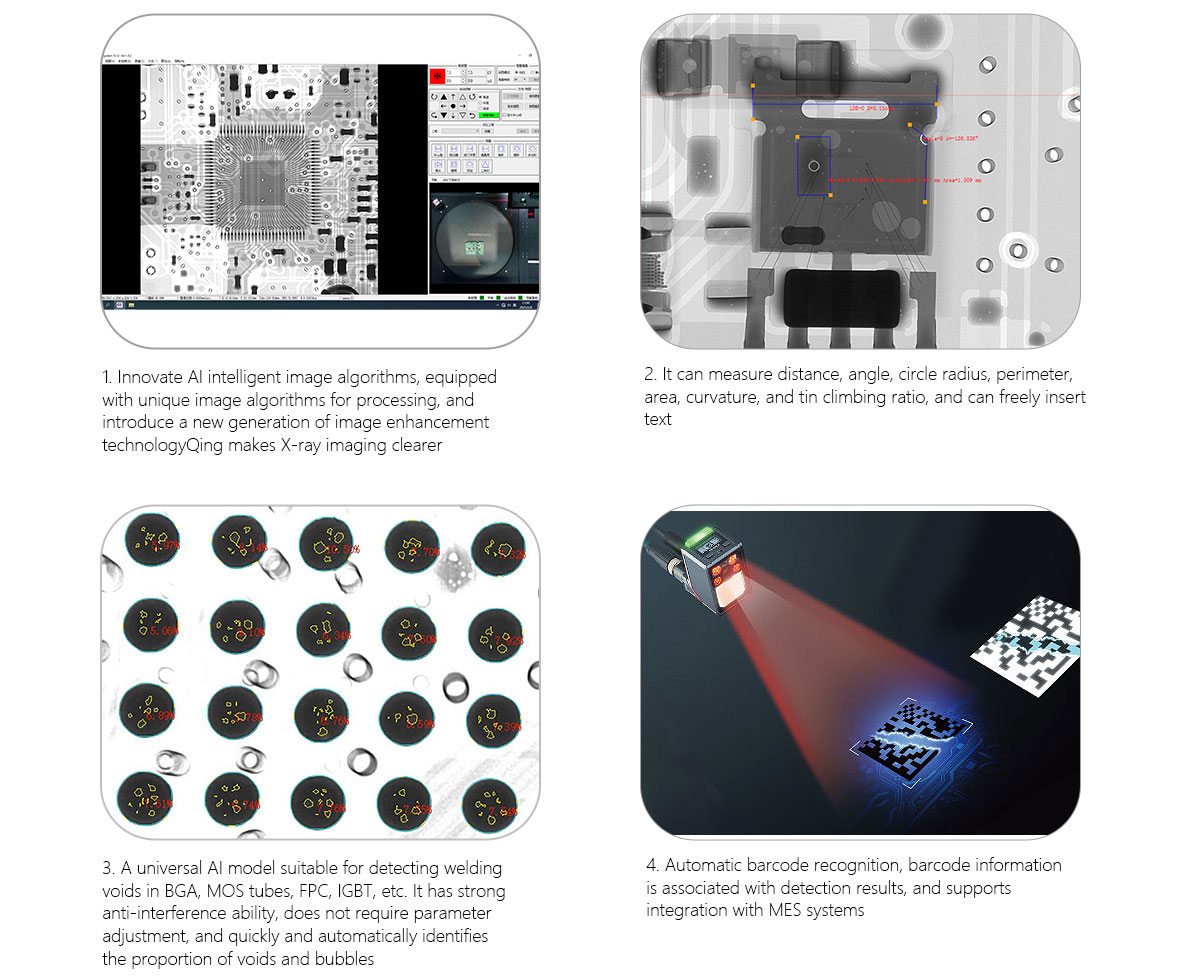

Function characteristics:

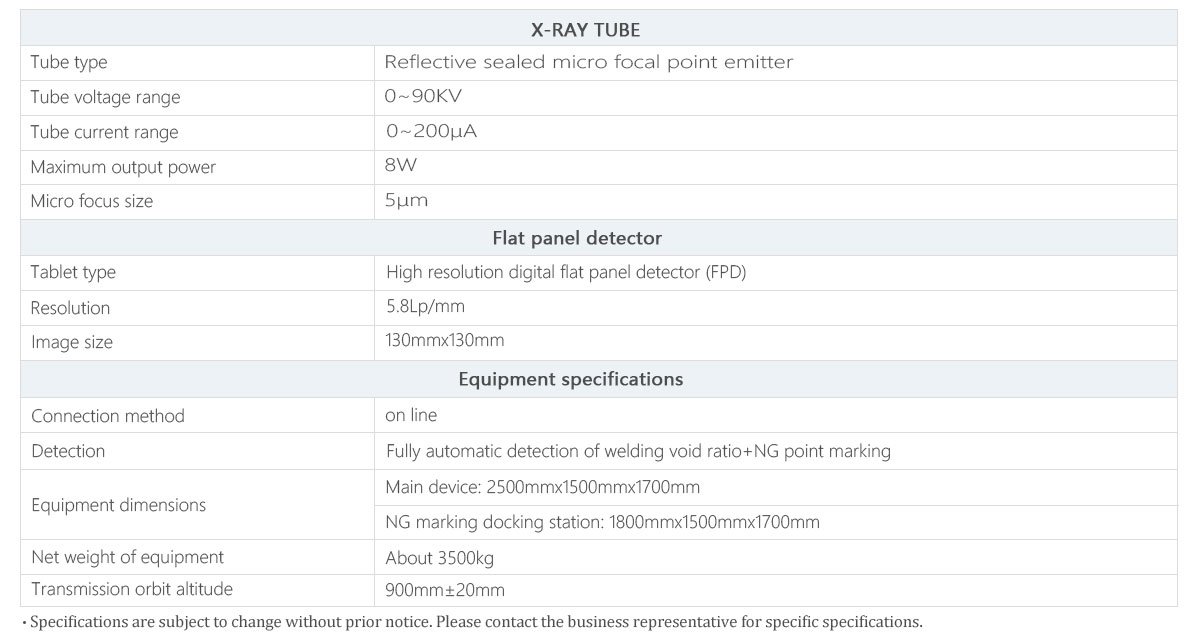

Technical Parameter:

Detection effect: