Features of Mini LED dedicated reflow soldering product:

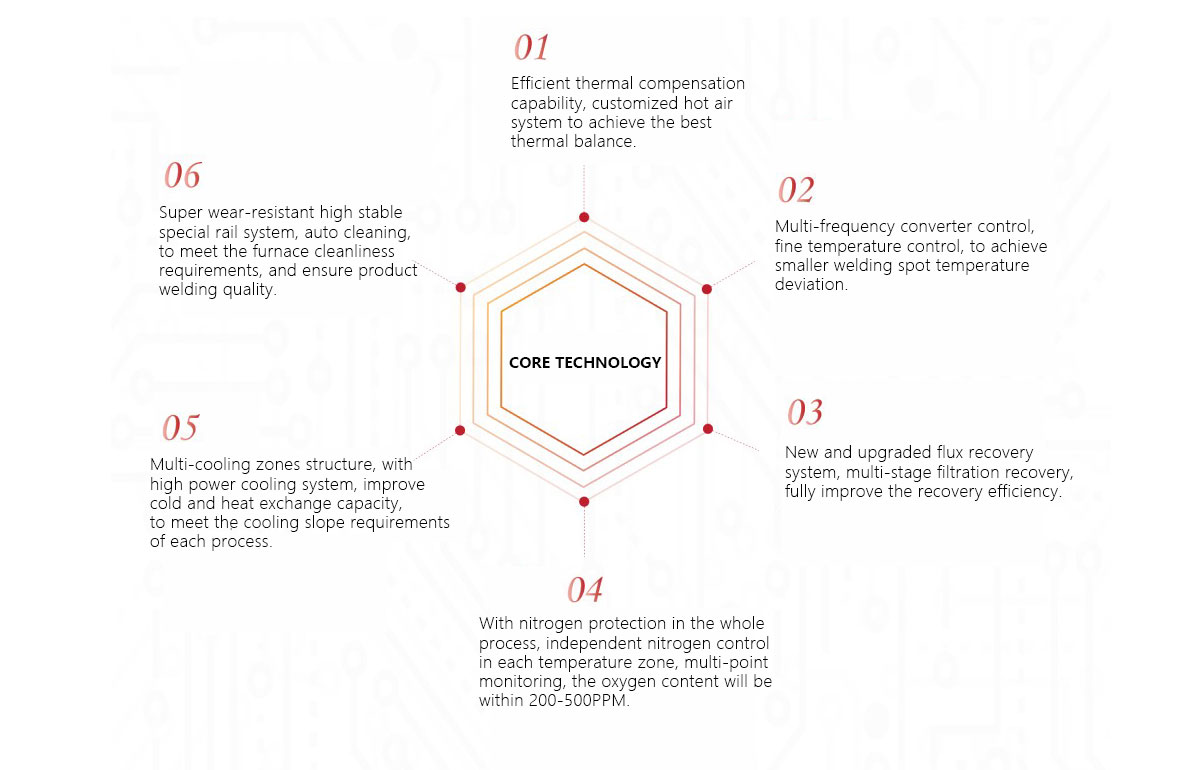

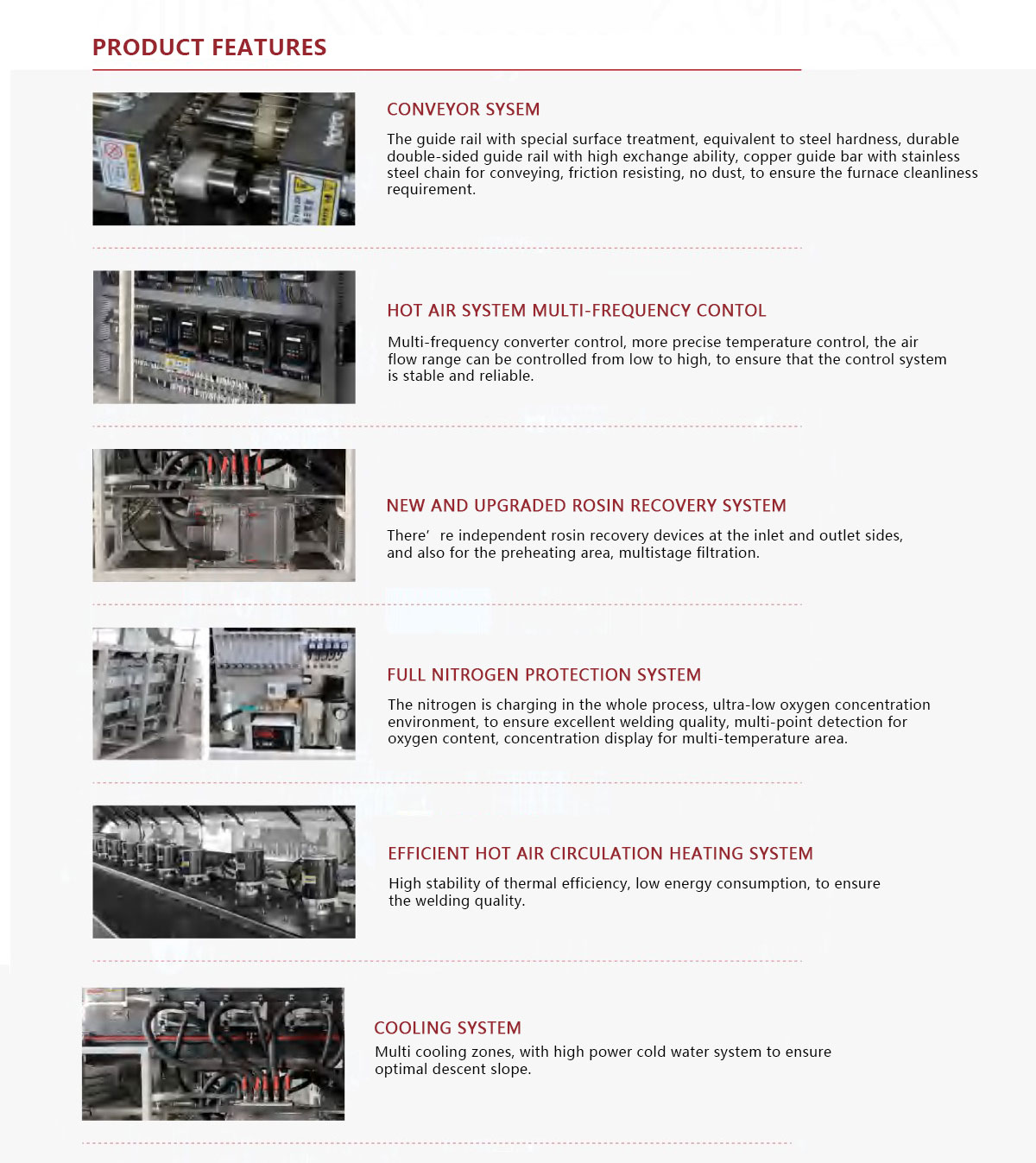

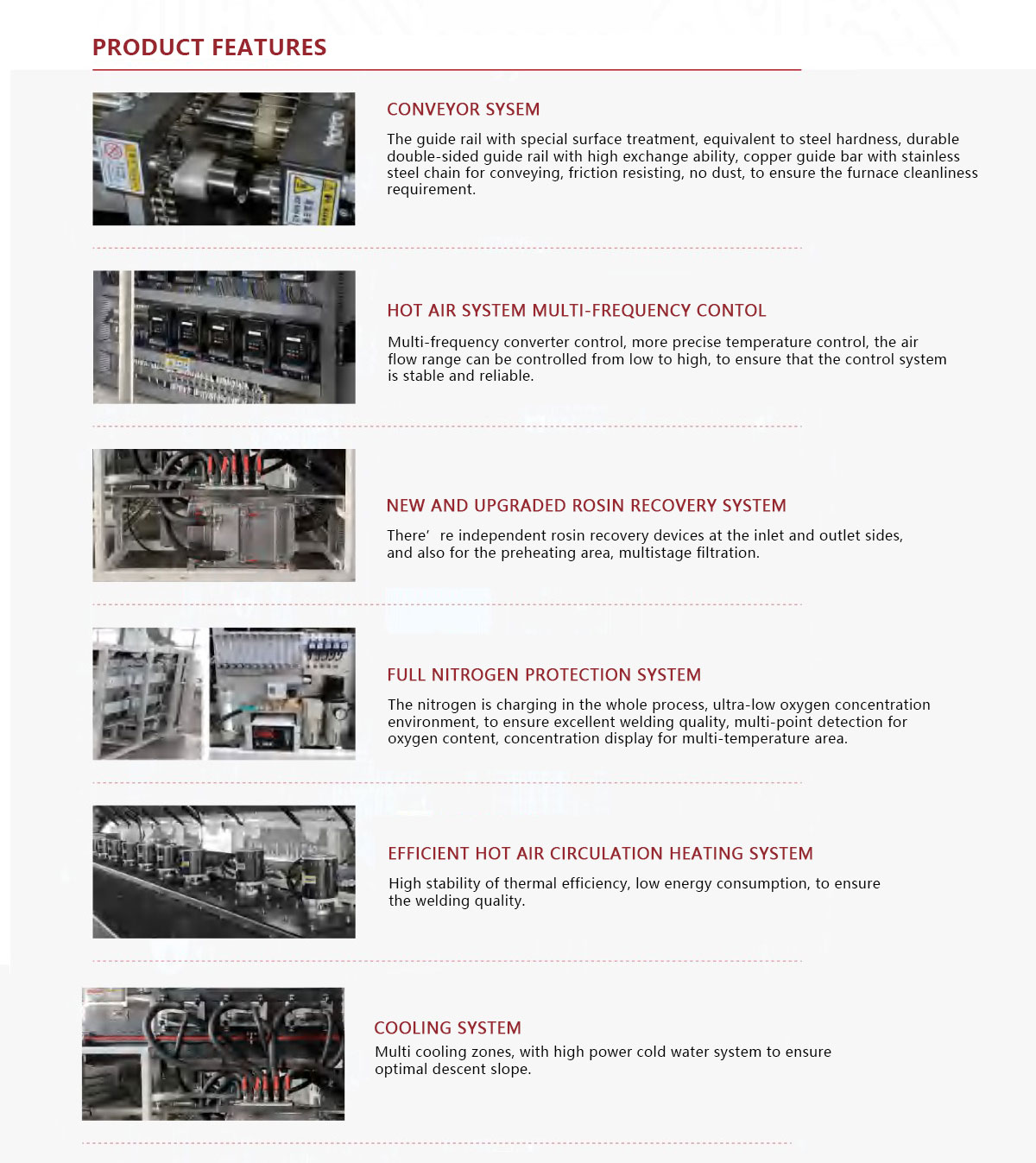

1. Efficient thermal compensation capability, targeted customization of hot air system to achieve optimal thermal balance;

2. Multi frequency converter control, precise temperature control, achieving smaller PCB solder joint temperature deviation;

3. Newly upgraded flux recycling system, multi-stage filtration recycling, fully improving recycling efficiency;

4. Full process nitrogen protection, independent control of nitrogen in each temperature zone, multi-point monitoring, can be controlled within 200-500PPM;

5. Multi cooling zone structure, combined with high-power cooling system, enhances the heat exchange capacity and meets the cooling slope requirements of various processes;

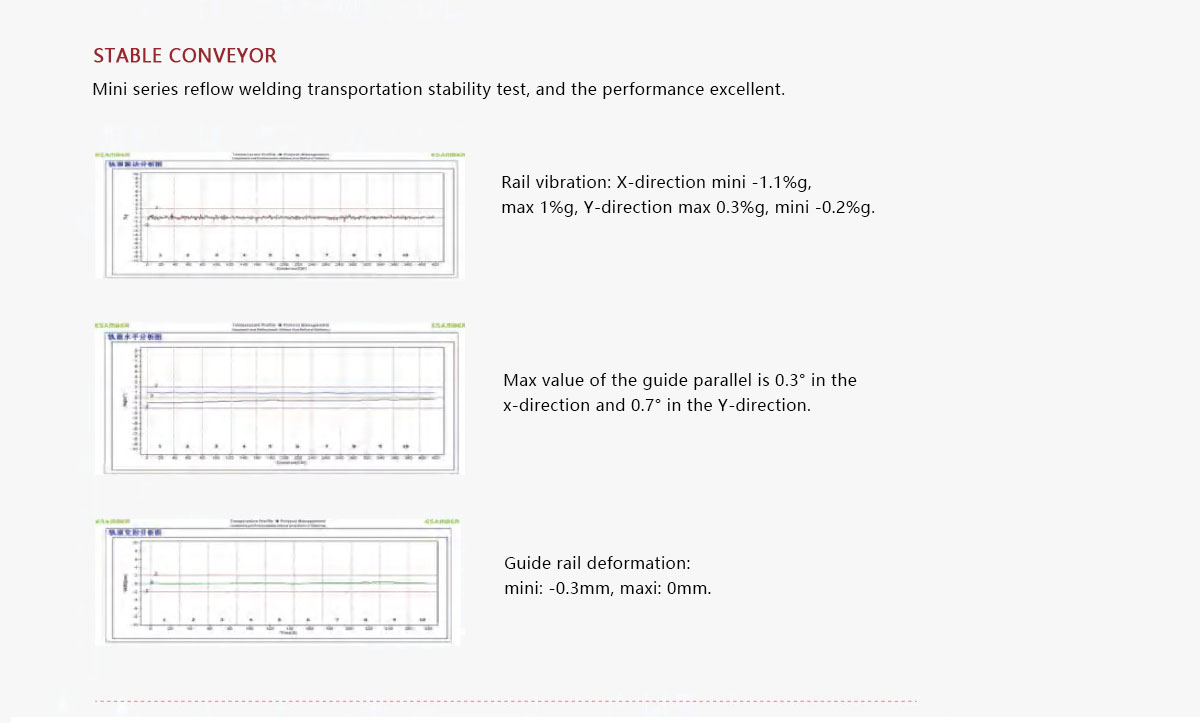

6. Ultra wear-resistant and highly stable special track system with automatic cleaning function, meeting the cleanliness requirements of the furnace cavity and ensuring the welding quality of the product;

Product parameters:

| Model No | MINI-R80 | MINI-R81 | MINI-R82 | MINI-R83 |

| Heati ng system |

| Heating zone structure | 10 heating zones, | 12 heating zones, | 10 heating zones, | 12 heating zones, |

|

| 20 heating modules | 24 heating modules | 20 heating modules | 24 heating modules |

| Heating zone length | 3670mm | 4390mm | 3670mm | 4390mm |

| Heating up time | 25min | 25min | 25min | 25min |

| Outlet Exhaust Diameter,valume | 2-Φ145,Exhaust demand 10m³/min x2 |

| Cooling system |

| Cooling type | Three cooling zones:forced water cooling |

| Cooling zone length | 1250mm |

| Chiller power | 5P Water chiller |

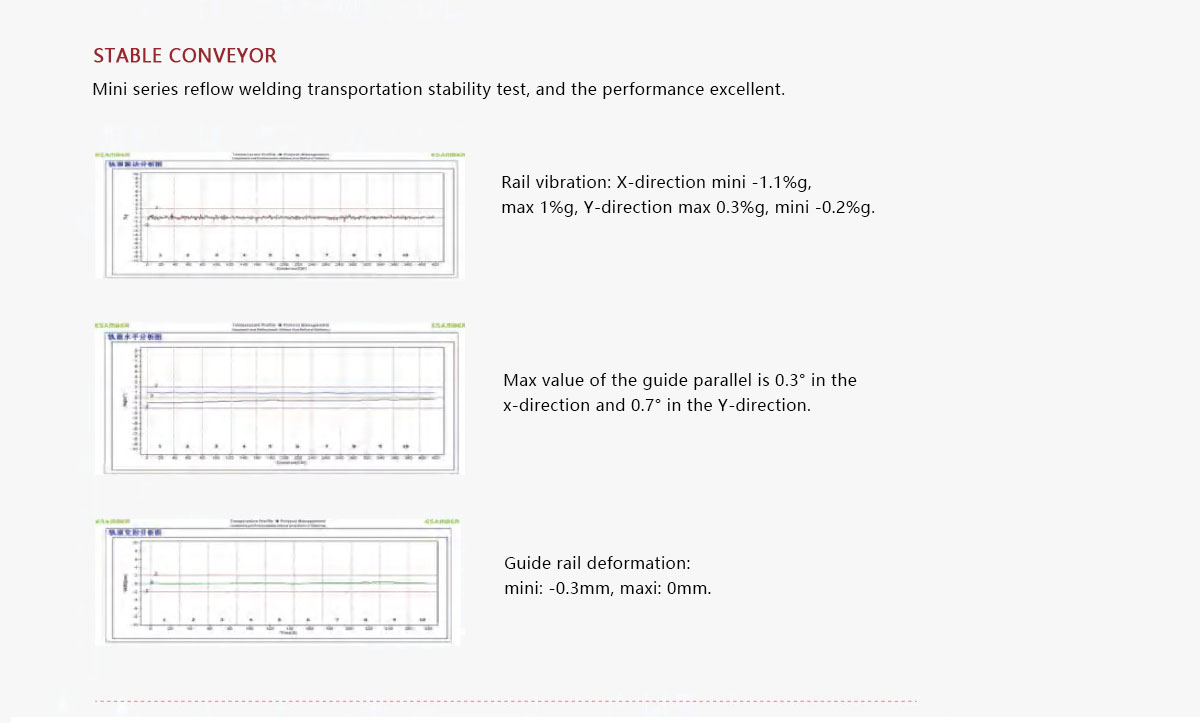

| Conveyor system |

| Conveyor Type | Chain+ mesh belt synchronous transmission |

| Conveyer Direction | L→R,R→L |

| Converyer Height | 900±20mm |

| Cmponent Height | Clearance above 30mm,Clearance below 20mm |

| Conveyor Speed | 300mm-2000mm/min |

| Guide rail structure | Dust free special hardened guide rail |

| PCB Width | Min50mm-max400mm (Option: max510mm) | min50mm-max250mm(Dual tracks) |

| min50mm-max450mm(Single track) |

| Fixed Rail Mode | Front rail Fixed(Option:Rear Rail Fixed) | The front and rear guide rails are fixed, and the |

| middle two guide rails can be movable. |

| Control system |

| Power AC3Ø 5W 380V 50/60HZ |

| Total Power | 96KW | 117KW | 96KW | 117KW |

| Startup Power | 38KW | 42KW | 38KW | 42KW |

| Normal consumption | 10KW | 12KW | 11KW | 13KW |

| Temp Control Range | Room temperature to 320℃ |

| Control type | PC+PLC Control system |

| Temp Control accuracy | ±1℃ | ±1℃ |

| PCB Temp Deviation | ±1℃ | ±2℃ |

| Data Storage | Process Data and status stotage |

| Power Outage Protection | Equipped with UPS |

| Operation Interface | Windows Chinese simplified, English online free switching |

| N2 area | Full nitrogen filling |

| MES communication protocol | Standard |

| Computer | Commercial computer |

| General |

|

| Dimension(LxWxH) | 6400x1580x1650mm | 7120x1580x1650mm | 6400*1710*1650mm | 7120*1710*1650mm |

| Weight | 2500-2700kg | 3000-3200kg | 2900-3100kg | 3500-3700kg |

| Flux recovery system | Standard |

| Color | Bright wrinkled white |

> Customization can be made according to customer needs.

FAQ:

Q: What is reflow oven machine?

A: In SMT (Surface Mount Technology), a reflow oven machine is an essential component used for soldering electronic components onto printed circuit boards (PCBs). It precisely heats the solder paste, allowing it to melt and create secure connections, a fundamental step in the electronics assembly process.

Q: How does a reflow machine work?

A: A reflow machine works by gradually raising the temperature to melt the solder paste on PCBs. This controlled heating process creates reliable solder connections between components and the PCB, ensuring the functionality and durability of electronic assemblies.

Q: What are the steps in the reflow process?

A: The reflow process in SMT involves several key steps, including preheating, solder paste reflow, and cooling. Preheating prepares the assembly for soldering, solder paste reflow creates connections, and cooling solidifies the solder joints, resulting in a completed electronic assembly.

Q: What is the difference between reflow oven and wave soldering machine?

A: Reflow ovens and wave soldering machines serve different soldering needs in SMT. Reflow ovens are used for surface mount components, heating solder paste to create precise connections. Wave soldering machines, on the other hand, are used for through-hole components, using a wave of molten solder to solder the bottom side of PCBs. Each method addresses distinct assembly requirements in electronics manufacturing.

H.F.X - Our Company

About H.F.X:

H.F.X is a leading provider of factory planning solutions and industrial inspection solutions. We have 4 wholly-owned factories that provide professional consulting and services to global customers. We have over 12 years of experience in electronic integrated solutions and industrial testing solutions. We not only provide a complete set of equipment, but also offer comprehensive technical support and services, and provide customers with more reasonable professional advice. We help many clients establish factories in LED, TV, mobile phone, DVB, EMS, and other industries around the world. We will establish factories in LED, TV, mobile phone, DVB, EMS, and other industries around the world. We have also obtained strict industry certifications such as CE, FDA, AERB, etc. Our products are exported to countries such as the United States, Germany, India, Singapore, Vietnam, Thailand, Canada, the United Kingdom, France, Italy, the Netherlands, Sweden, Mexico, Brazil, etc. We are trustworthy.

Exhibition:

For SMT factory setup and industrial non-destructive testing, we can provide you with:

1. We provide you with complete SMT solutions and industrial testing solutions

2. We Provide Core Technology With Our Equipments

3. We provide the most professional technical services

4. We have rich experience in establishing SMT factories and industrial testing

5. We can solve any problems related to SMT and industrial testing

Mini LED dedicated reflow soldering