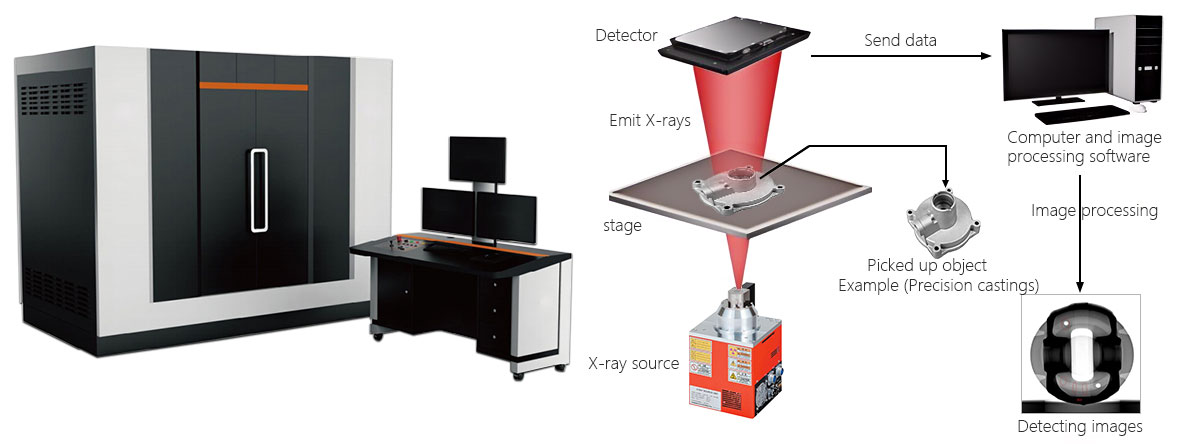

Equipment Overview:

1.Industrial X-ray testing equipment is a technical device that uses the penetrability of X-rays to perform non-destructive testing on the internal

structure of objects;

2.It emits X-rays, penetrates the object being detected, and then receives the X-rays passing through the object to form an image;

3.Based on the characteristics of the image, it is possible to determine whether there are defects, foreign objects, structural abnormalities, and

other issues inside the object.

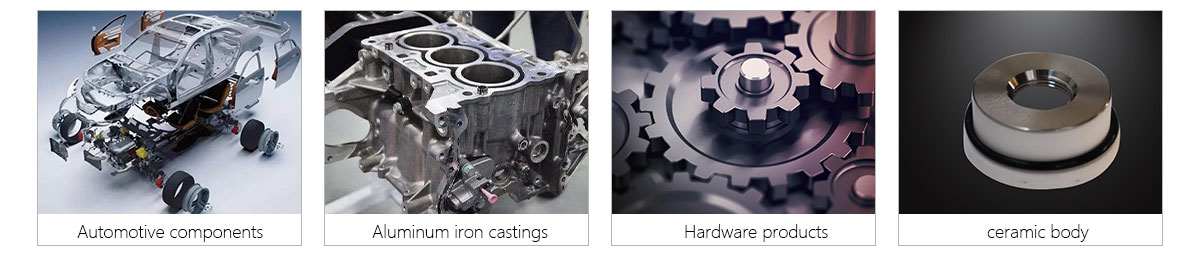

Application Fields:

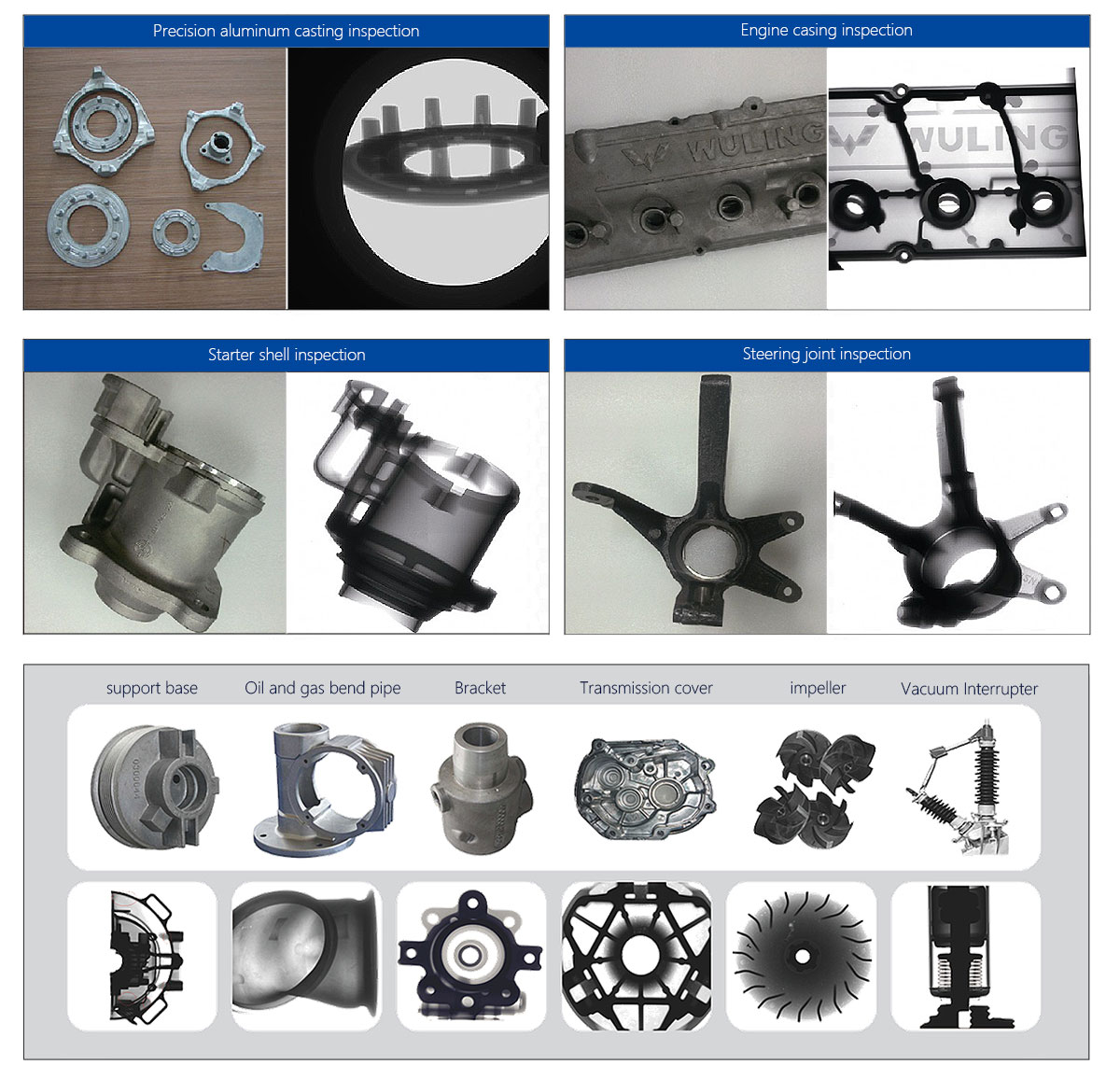

1.Mainly used in non-destructive testing of automotive components, castings, welds, aerospace, and other related industries;

2.Suitable for non-destructive testing of various lightweight flat products such as metal castings, automotive parts, plastic products, rubber

products, refractory materials, resin materials, composite materials, and ceramic bodies;

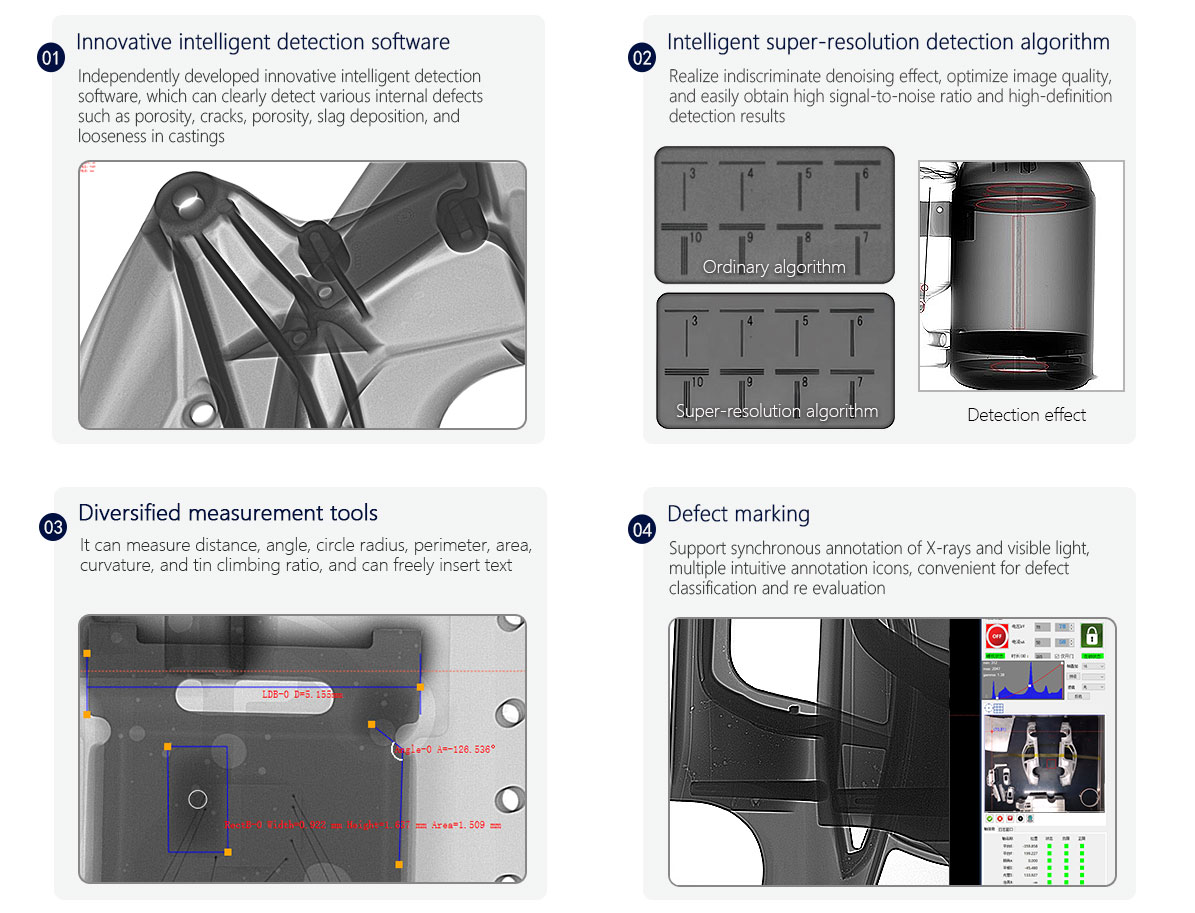

Feature Highlights:

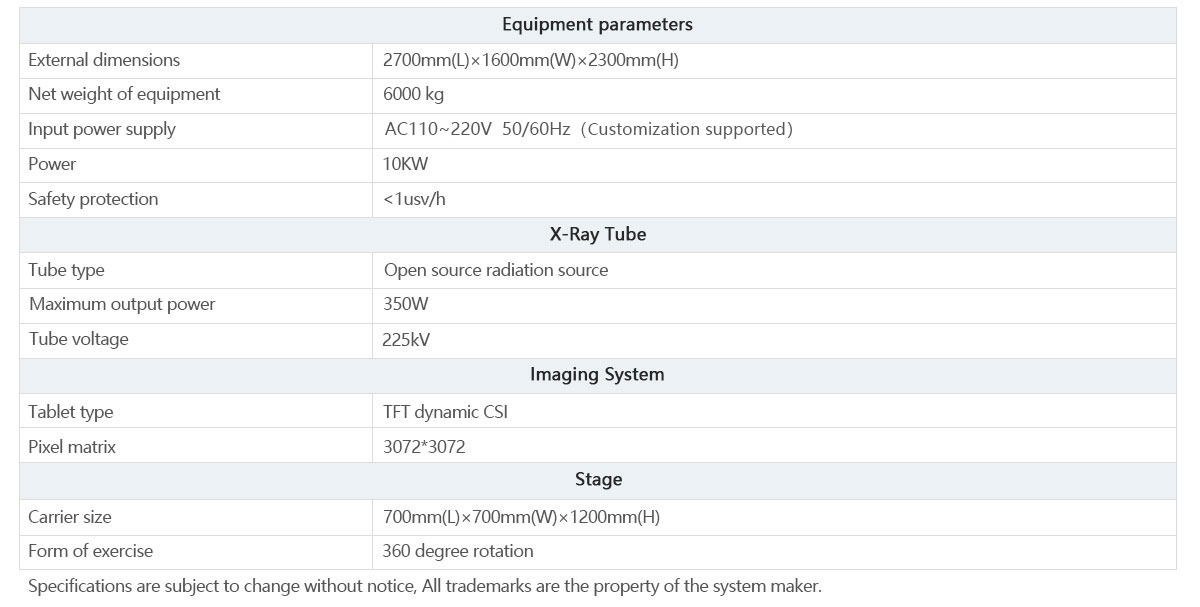

Product Parameters:

Functions and Feature:

1.Easy to operate, quickly identify target defects, two-hour training to get started;

2.Multi functional cargo platform, 360 degree rotation and movement;

3.C-arm six axis linkage detection method, no dead angle detection;

4.Multiple safety protections such as safety interlock and automatic shutdown of radiation sources in safety status;

5. The six sides of the equipment are designed with steel, lead, and steel to isolate radiation and prevent leakage, making operation safer and more reliable;

6. Real time monitoring of radiation values with automatic alarm function, providing multiple protections for the personal safety of operators;

Detection effect: