Product overview:

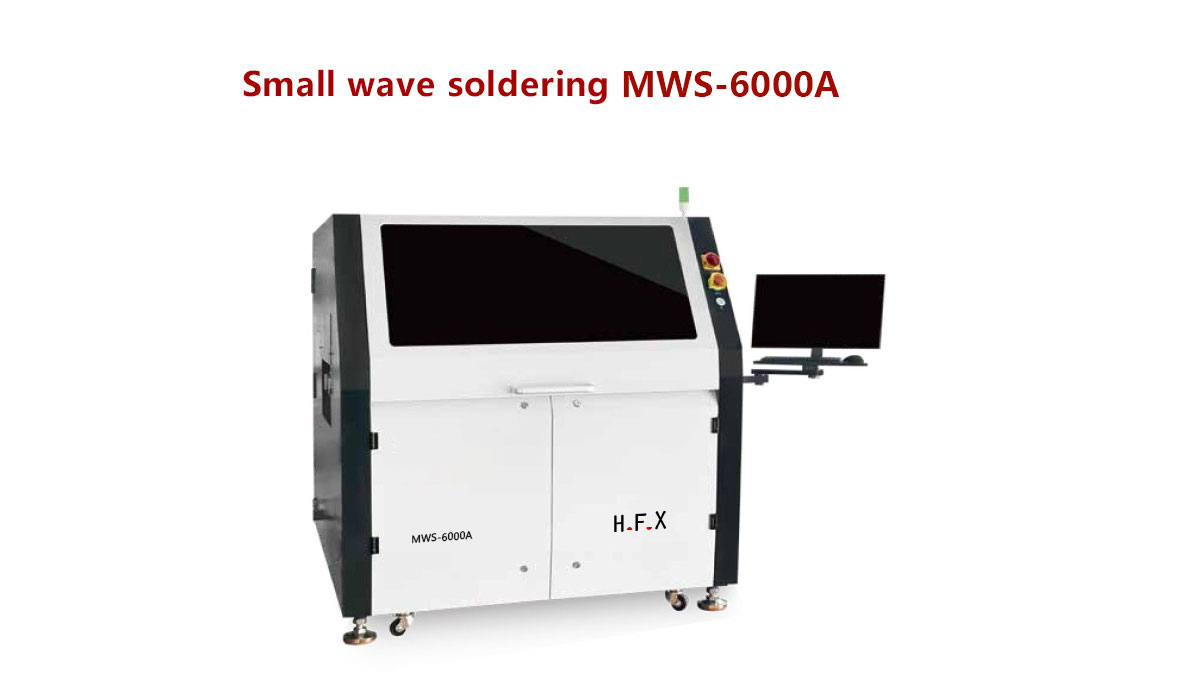

H. F.X MWS-6000A selective wave soldering machine is designed to provide excellent soldering results for large-scale PCB assembly lines. MWS-6000A is designed and assembled by H.F.X in China, renowned for its excellent cost-effectiveness, modular and compact design, and flexible scalability, allowing manufacturers to easily expand production capacity by adding more machines as needed.

With its low energy consumption, high-quality components, and intelligent software control, SUNFLOW FS/450 is becoming the preferred choice for global electronics manufacturers.

Small Selective Soldering MWS-6000A Feature:

Equip with spraying, preheating and welding units which can complete the whole welding process in a small machine.

Cover small area, shorter than the standard SUNFLOW machine.

Real time monitoring and recording of welding process.

Basic machine module:

| Flux Module | Preheat Module | Soldering Module | Conveyor System |

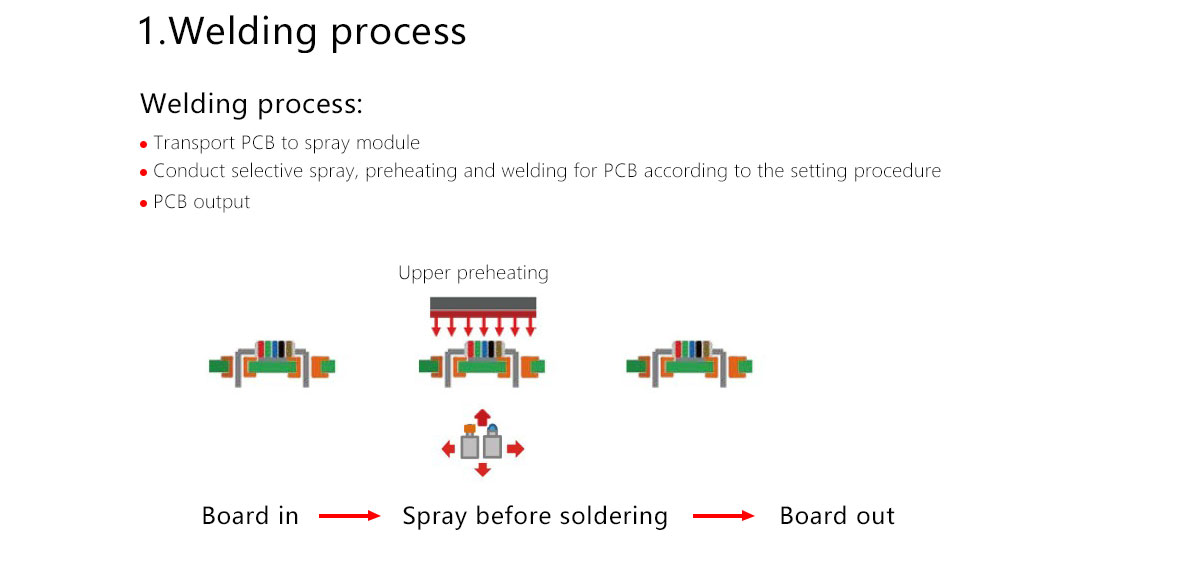

Soldering process:

Send a PCB to the specified location;

PCB selective spraying, preheating and soldering are according to the setup program;

PCB is transported out。

Working Process:After PCB is moved to flux area, the spray head is targeted to the programed position and the flux is applied only to the solder joint to be made.After preheating, the electromagnetic pump moves to the target area and solder joint is made.

Product parameters:

| Specifications | |

| Model NO. | MWS-6000A |

| General Parameters | |

| Overall dimension(Not include indicator light and monitor)(mm) | 1550(L)*1930(W)*1630(H) |

| Equipment Weight (kg) | 1050 |

| PCB Top Side Clearance(mm) | 120 |

| PCB Bottom Side Clearance (mm) | 60 |

| PCB process edge(mm) | ≥3 |

| Conveyor Height From Floor(mm) | 900±20 |

| PCB Conveying Speed(m/min) | 0.2-10 |

| Max PCB Weight(kg) | ≤8 |

| PCB ThicknessWith Jig(mm) | 1-6 |

| ConveyorWidth Adjustment Range(mm) | 50-450 |

| Conveyor Width Adjustment Mode | Electric |

| PCB Conveying Direction | Left to right |

| Air Input Pressure(Mpa) | 0.6 |

| Nitrogen Supply | Offered by customer |

| Nitrogen Input Pressure(Mpa) | 0.6 |

| Nitrogen Consumption (m³/h) | 1.5 |

| Required Purity of Nitrogen(%) | >99.999 |

| Supply Voltage(VAC) | 380 |

| Frequency(HZ) | 50/60 |

| Max Power Consumption(kw) | <11 |

| Max Current(A) | <20 |

| Ambient Temperature(℃) | 10-35 |

| Machine Noise Level (dB) | <65 |

| Communication Interface | SMEMA |

| Soldering System | |

| Max.Soldering distance of Xaxis(mm) | 510 |

| Max.Soldering distance of Yaxis(mm) | 450 |

| Max.Soldering distance of Z axis(mm) | 60 |

| Nozzle outer diameter (mm) | 5、6、8、9、10、12、14 |

| Nozzle inner diameter(mm) | 2.4、3、4、5、6、8、10 |

| Max soldering wave height(mm) | 5 |

| Solder potcapacity (kg) | Approx.13kg(Sn63Pb)/solderpot |

| Approx.12kg(lead-free)/solderpot | |

| Max soldering temperature(℃) | 330 |

| Soldering heating power(kw) | 1.15 |

| Preheating System | |

| Preheat temperature range(℃) | <200 |

| Heating power(kw) | 5 |

| Top side preheating | Hot air |

| Spraying System | |

| Max.stroke of Xaxis (mm) | 510 |

| Max.stroke of Y axis(mm) | 450 |

| Spray height(mm) | 60 |

| Location speed(mm/s) | <200 |

| Flux box capacity (L) | 2 |

| Remarks:Other models of MWS series can be customized. | |

> Customization can be made according to customer needs.