Product Introduction:

1. Fully automatic cleaning mode: The mesh board is thrown up and down, and the high-pressure spray system sprays heated cleaning solution, which can automatically clean, rinse, and dry the entire process of the mesh board in all directions;

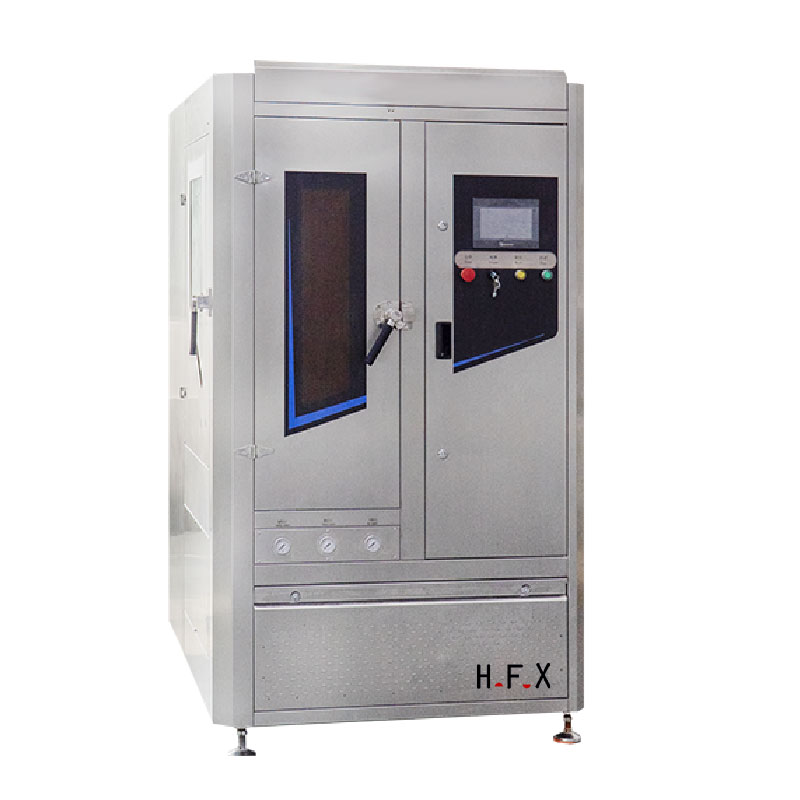

2. Full process visualization: Visual window and LED light device, making the cleaning process clear at a glance;

3. The most scientific nozzle design (patent): using 8 left and right spray distributions - completely solving the cleaning blind spot, the spray and nozzle are detachable;

4. Visual nozzle pressure adjustable: solves the collision and splashing problems of small workpiece sizes under high-pressure spray conditions during cleaning;

5. Installing photoelectric sensors at the observation window and the entrance of the mesh board to protect personal safety, and the standard dilution tank/rinse tank heating system greatly improves cleaning efficiency and shortens cleaning time;

6. Comprehensive cleaning system: compatible with running water washing or chemical cleaning, for SMT; Thoroughly and effectively clean the organic and inorganic pollutants such as rosin, water-soluble flux, cleaning free flux/solder paste left on the surface of THT PCBA after welding;

7. Body quality: The overall body is made of 304 stainless steel, and it is resistant to acid, alkaline and other cleaning solutions;

8. Cleaning the built-in filtering device can achieve solvent recycling and reduce solvent usage;

9. There is an emergency stop button and leakage protection function when a fixed fault occurs.

Application case:

Suitable for cleaning SMT steel mesh, copper mesh, adhesive mesh, printing adhesive fixtures, PCB misprinted boards, and PCBA. It can effectively clean the surface after printing and residual contaminants such as solder paste and red glue on the hole wall.

Product parameters:

| Project | FM-40D |

| Effective cleaning size: | 736mm(L) ×736mm(W) × 40mm(H) |

| Equipment appearance dimensions: | 1700mm(L) ×1200mm(W) × 2000mm(H) |

| Power/Air Source: | Three phase five wire system, 380V/18Kw (rated power)/0.45Mpa-0.7Mpa |

| Tank capacity: | >80L * 2 pieces |

| Spray tank dilution tank heater power: | 6KW |

| Cleaning time: | 3-5 minutes (solder paste) |

| Cleaning temperature (liquid): | Room temperature~70 ℃ (adjustable) |

| Rinse time: | 1-3 minutes (solder paste) |

| Rinse temperature (DI water): | Room temperature~70 ℃ (adjustable) |

| Drying time: | 3-5 minutes/(adjustable) |

| Cleaning size range setting: | 50—736mm |

| Whole machine weight | 750KG |

> Customization can be made according to customer needs.