Application area:

Selective wave soldering is a special form of wave soldering invented to meet the development requirements of through-hole component soldering.

Mainly suitable for soldering through-hole components in high-end electronic products. For example, industries such as military electronics,

automotive electronics, and switch power supply products that require high welding reliability.

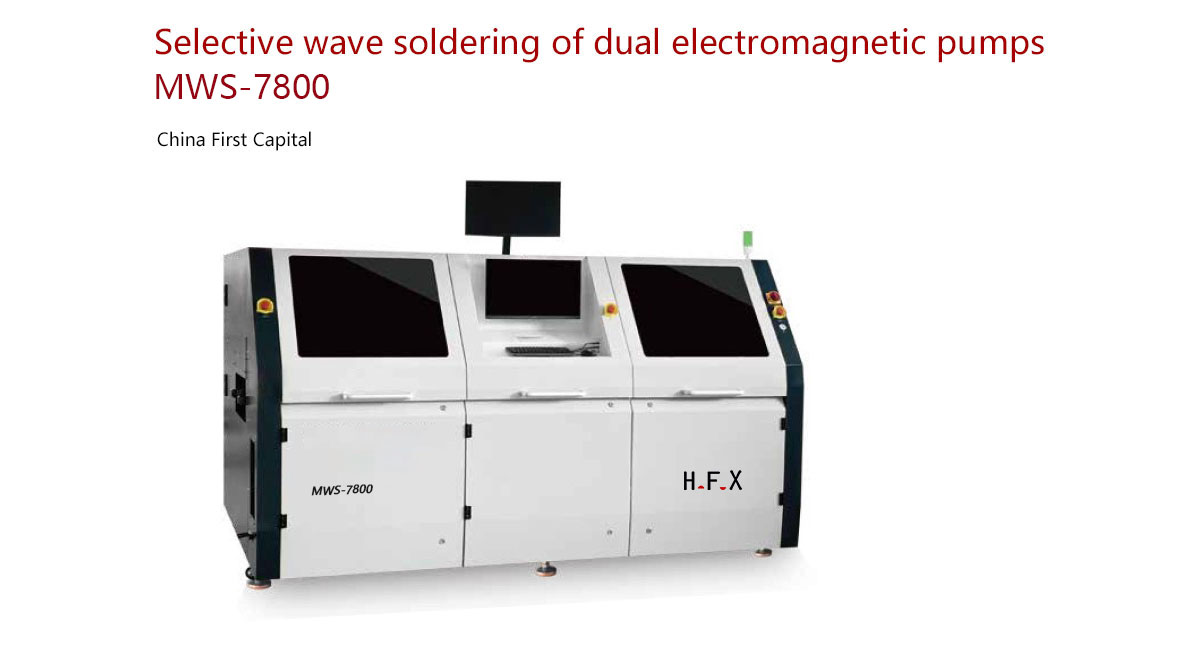

Selective soldering MWS-7800 Feature:

High efficiency and energy saving,top quality;

Double solder pots independent lifting;

Display and record the whole process welding status;

Pioneered electromagnetic pump technology in China;

Nozzle spacing automatic adjustment.

Basic machine module:

| Flux Module | Preheat Module | Soldering Module | Conveyor System |

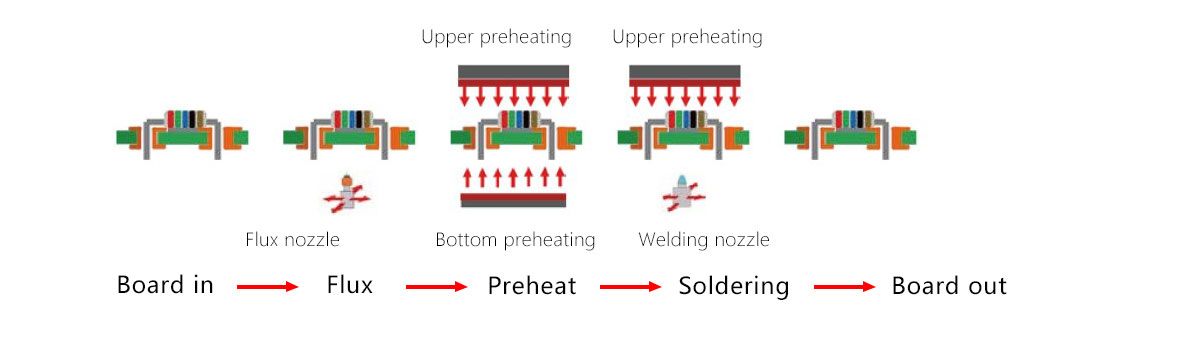

Soldering process:

Transport the PCB to flux module

Spray head move to programed area and flux is applied only to the soldering joint to be made

Top -side and bottom-side preheat

Programed electromagnetic pump soldering perfectly formed solder joint

PCB is transported out

Working Process:After PCB is moved to flux area,the spray head istargeted to the programed position and thefluxis applied only tothe solder jointto bemade.After preheating,the electromagnetic pumpmoves to the target areaand solder joint is made.

Product parameters:

| Specifications | ||

| Model NO. | MWS-7800 | MWS-7800A |

| General Parameters | ||

Overalldimension(mm)(Not include indicator light andmonitor) | 2710(L)*1930(W)*1630(H) | 3040(L)*2240(W)*1630(H) |

| Equipment Weight(kg) | 1650 | 2200 |

| Max PCBsize(mm) | 510(L)*450(W) | 610(L)*610(W) |

| Min PCB size(mm) | 120(L)*50(W | 120(L)*50(W |

| PCB Top Side Clearance(mm) | 120 | 120 |

| PCB Bottom Side Clearance (mm) | 60 | 60 |

| PCB process edge(mm) | ≥3 | ≥3 |

| Conveyor Height From Floor (mm) | 900±20 | 900±20 |

| PCB Conveying Speed(m/min) | 0.2-10 | 0.2-10 |

| Max PCB Weight(kg) | ≤8 | ≤8 |

| PCB Thickness With Jig(mm) | 1-6 | 1-6 |

| Conveyor Width Adjustment Range(mm) | 50-450 | 50-610 |

| Conveyor Width Adjustment Mode | Electric | Electric |

| PCB Conveying Direction | Left to right | Left to right |

| Air Input Pressure(Mpa) | 0.6 | 0.6 |

| Max Air Consumption(m³/h) | 5 | 5 |

| Nitrogen Supply | Offered by customer | Offered by customer |

| Nitrogen Input Pressure(Mpa) | 0.6 | 0.6 |

| Nitrogen Consumption(m³/h) | 1.5/single solder pot | 1.5/single solder pot |

| Required Purity of Nitrogen(%) | >99.999 | >99.999 |

| Supply Voltage(VAC) | 380 | 380 |

| Frequency(HZ) | 50/60 | 50/60 |

| Max Power Consumption (kw) | <32 | <38 |

| Max Current(A) | <60 | <64 |

| Ambient Temperature(℃) | 10-35 | 10-35 |

| Machine Noise Level (dB) | <65 | <65 |

| Communication Interface | SMEMA | SMEMA |

| Soldering System | ||

| Max.Soldering distance of Xaxis(mm) | 510 | 610 |

| Max.Soldering distance ofY axis(mm) | 450 | 610 |

| Max.Soldering distance of Z axis(mm) | 60 | 60 |

| Nozzle outer diameter (mm) | 5、6、8、9、10、12、14 | 5、6.8、9、10、12、14 |

| Nozzle inner diameter (mm) | 2.4、3、4、5、6、8、10 | 2.4、3、4、5、6、8、10 |

| Max soldering wave height (mm) | 5 | 5 |

| Solder pot capacity (kg) | Approx.13kg(Sn63Pb)/solder pot | Approx.13kg(Sn63Pb)/solder pot |

| Approx.12kg(lead-free)/solder pot | Approx.12kg(lead-free)/solder pot | |

| Max soldering temperature(℃) | 330 | 330 |

| Soldering heating power (kw) | 1.15/solderpot | 1.15/solderpot |

Minimum distance between nozzle center of the two solder pots(mm) | 95 | 95 |

Maximum distancebetween nozzle center of the two solderpots(mm) | 230 | 310 |

| Preheating System | ||

| Preheat temperature range(℃) | <200 | <200 |

| Heating power (kw) | 17 | 21.5 |

| Heating mode | Hot air+Infrared | Hot air+Infrared |

| Top side preheating | Hot air | Hotair |

| Spraying System | ||

| Max.stroke of Xaxis (mm) | 510 | 610 |

| Max.stroke of Yaxis(mm) | 450 | 610 |

| Spray height(mm) | 60 | 60 |

| Location speed(mm/s) | <400 | <400 |

| Spray head automaticallycleaning | Program control | Program control |

| Fluxbox capacity (L) | 2 | 2 |

| Remarks:Other models of MWS double pumps series can be customized. | ||

> Customization can be made according to customer needs.